Introduction to the ceramic ball mill

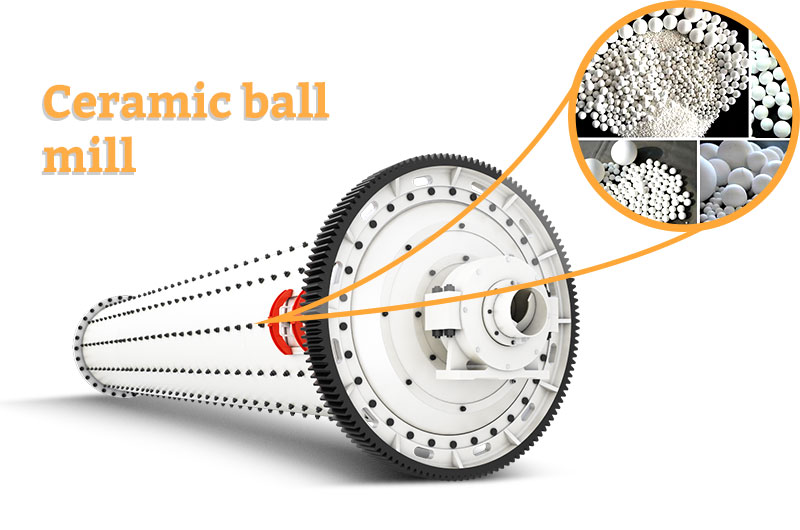

Ceramic ball mill is mainly used in material mixing, grinding. Henan Fote Heavy Machinery Co., Ltd has two kinds of grinding ceramic ball mill, one is dry grinding ceramic ball mill, and another is wet grinding ceramic ball mill. The machine can use different liner types according to different production needs. The fineness of the grinding is controlled by grinding time.

The ceramic ball mill machinery has the advantages of less investment, lower energy consumption, novel structure, easy operation, stable and reliable performance and so on, which is suitable for grinding common and special materials. Customers can choose suitable types of ceramic ball mill jars according to the specific gravity, hardness, and capacity of materials.

It also named the ceramics ball mill, is a small ball mill mainly used for material mixing and grinding considering its products having features of regular granularity and power saving. China Fote’s ceramic ball mill can do both dry and wet grinding and can choose different lining boards to meet various demands according to different production requirements.

The grinding ceramic ball mill uses different ball mill ceramic liner types according to production needs to meet different needs. The finess of ceramic ball mills depend on the grinding time. The electro-hydraulic machine is auto-coupled and decompressed to reduce the starting current. Its structure is divided into integral and independent.

The ceramic ball mill media is ceramic ball

Types of ceramic ball mill

FTM Machinery, as the ceramic ball mill supplier, produced 60T, 40T, 10T, and 0.1-1T ceramic ball mill according to different productivities.

| Model |

Feeding capacity

(t/time) |

Shell rotation speed

(r/min) |

Reference motor

(kw) |

| 600×700 |

0.05 |

50 |

2.2 |

| 800×600 |

0.075 |

42 |

3 |

| 900×1200 |

0.2 |

38.5 |

5.5 |

| 1300×1500 |

0.5 |

33 |

7.5 |

| 1500×1800 |

1.2 |

28.5 |

11 |

| 1800×2000 |

1.5 |

24 |

15 |

| 2600×2800 |

5 |

16.5 |

37 |

| 3000×3800 |

10 |

14.5 |

57.2 |

| 3200×4600 |

15 |

13.5 |

75 |

Advantages and features of the ceramic ball mill

The grinding fineness depends on the milling time. The motor of the ceramic ball mill is started by the coupling reduce voltage which lowers the starting electricity and the ball mill’s structure is divided into integral type and freestanding type; advantages of the ceramic ball mill are lower investment, energy saving, structure novelty, simply operated, used safely, ability even, etc.

The ceramic ball mill is suitable for mixing and milling of the general and special material. Users could choose the proper type and line, media material depending on material ratio, rigidity, and output size, etc.

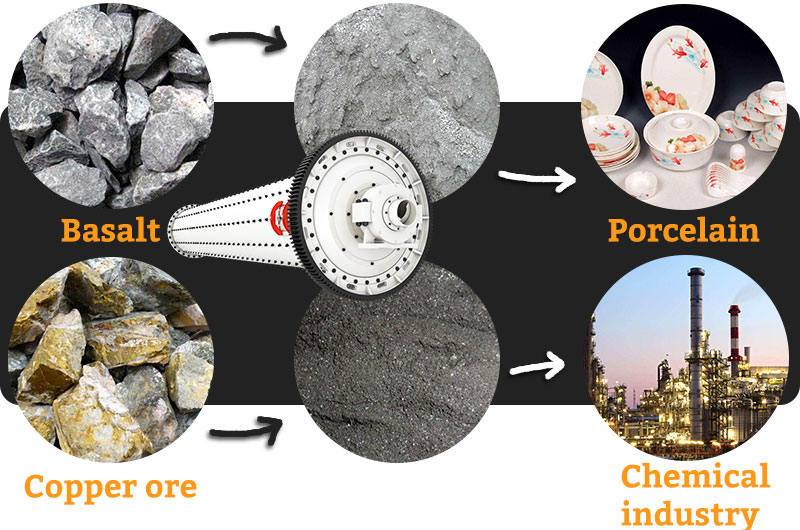

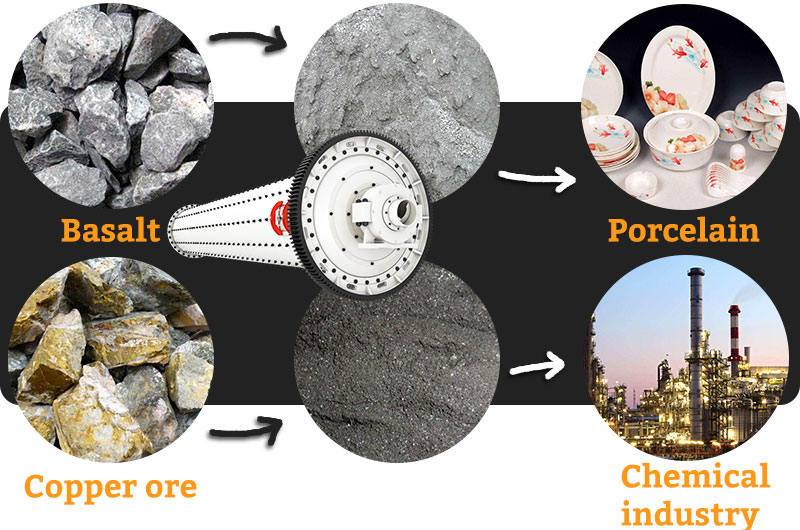

Application of the ceramic ball mill

Ceramic ball mill is the typical grinding equipment which us ball mill ceramics, greatly improves the grinding fineness. Compared with the traditional ball mill, such kind of ball mill has a great advantage in function, structure, and operation. This machine also has great capacity, high technology, and no noise, which plays an important role in the field of Metallurgy, building materials, chemicals, industry.

The small tonnage glaze ball mill is the main machine used to make glaze ceramic grinding balls by the industries of producing household porcelain, electrical porcelain and building porcelain. It is applied to grind different glaze materials with different colors and has features of good grinding quality, compact structure, little noise, and simple maintenance.

The ceramic ball mill is a wet type grinding machine for the ceramic materials which can realize high efficiency for fine grinding of the medium crushed materials. Then, how to ball mill ceramic powder? Once users add raw materials, water, and ceramic grinding media in a proper proportion into the cylinder of the ball mill, they will get the ideal product particles by adjusting the required grinding period.

The fine material slurry is especially suitable to be applied in the industries of large-sized household porcelain, electrical porcelain, building porcelain and chemical engineering. And that’s the main reason why the producers love ceramic glaze ball mill so much.According to the different demands, the ceramic grinding ball mill

can produce different range of the partical ship.

Materials that are grinded by ceramic ball mill can be made into porcelain and applied in the chemical industry

Small production ball mill for ore grinding

This is a 3-foot by 6-foot continuous ball mill, and this machine will process one ton an hour at 65 mesh. You can actually process finer than that, down to about 200 mesh, but the throughput goes down. To the feed side, you can put three quarter to one inch minus here. then, ore enters into the scoop of ball mill, with a two-ton charge of balls. The material works its way through the ball mill, which turns about 35 RPM, with the water addition. To the discharge, they will go on to the shaker tables for concentration.

Here are three different size balls we use. And you add equal amounts of each size ball when you charge the mill. And then as the balls wear, you keep putting in larger balls. Again, it is about a two ton charge of balls. The machine empty weighs about 8,500 pounds, with the charge of balls, it weights about 12,500 pounds.

let’s look inside the ball mill now, you can see it has cast armor lining the inside of mill. This is the feed side, and across the mill, here is the discharge side, and it has a grate to keep the balls in. There is an augur in there that screws the material back in, so only the finest material can exit the mill.

The mill weighs a little more than 3 tons, and you can easily turn the mill with one hand. So, it’s a really smooth mill, not a lot of friction. It runs with a 25 horse, 3-phase motor. And here in a couple weeks, we’ll be getting this mill up and running and put a lot of balls in and run some material.

Installation of ceramic ball mill

First. Installing the main bearing. In order to avoid the aggravating the wear of shoulder and bearing lining of the hollow journal, the gap between the base plate of two main ceramic ball mill bearings is no more than 0.25mm.

Second. Install the barrel of ceramic ball mill. According to the specific conditions, the pre-assembled whole simplified parts can be directly installed or installed in several parts. Check and adjust the center line of the journal and ceramic ball mill.

Third. Install transmission parts such as pinion gears, couplings, reducers, motors, etc. In the process of installation, measurements and adjustments should be made according to product technical standards. Check the radial slip off the ring gear and the meshing performance of the pinion, concentricity of reducer and pinion, and the concentricity of motor and reducer. Until all installations are ready, the foundation bolts and the main bearing bottom plate can be watered.

These ceramic ball mills are for sale. If you are interested in these kind of ceramic lined ball mill, please leave your message on the message board.

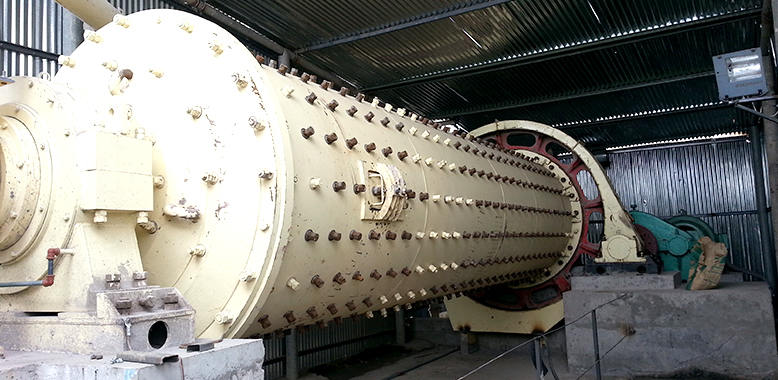

Ceramic ball mill site

Ceramic Ball Mill Technical Parameter

| Model |

Feeding capacity

(t/time) |

Shell rotation speed

(r/min) |

Reference motor

(kw) |

| 600×700 |

0.05 |

50 |

2.2 |

| 800×600 |

0.075 |

42 |

3 |

| 900×1200 |

0.2 |

38.5 |

5.5 |

| 1300×1500 |

0.5 |

33 |

7.5 |

| 1500×1800 |

1.2 |

28.5 |

11 |

| 1800×2000 |

1.5 |

24 |

15 |

| 2600×2800 |

5 |

16.5 |

37 |

| 3000×3800 |

10 |

14.5 |

57.2 |

| 3200×4600 |

15 |

13.5 |

75 |

| Model |

Feeding capacity

(t/time) |

Shell rotation speed

(r/min) |

Liner material |

| 600×700 |

0.05 |

50 |

Chinaware,silicon,rubber or metal(the related motor power varied as per the different liner materials and grinding materials) |

| 800×600 |

0.075 |

42 |

| 900×1200 |

0.2 |

38.5 |

| 1300×1500 |

0.5 |

33 |

| 1500×1800 |

1.2 |

28.5 |

| 1800×2000 |

1.5 |

24 |

| 2600×2800 |

5 |

16.5 |

| 3000×3800 |

10 |

14.5 |

| 3200×4600 |

15 |

13.5 |