With the constant development of the global economy and the rise of the construction industry, crawler mobile crushing and screening equipment has been favored by more and more customers and has become indispensable equipment in infrastructure construction.

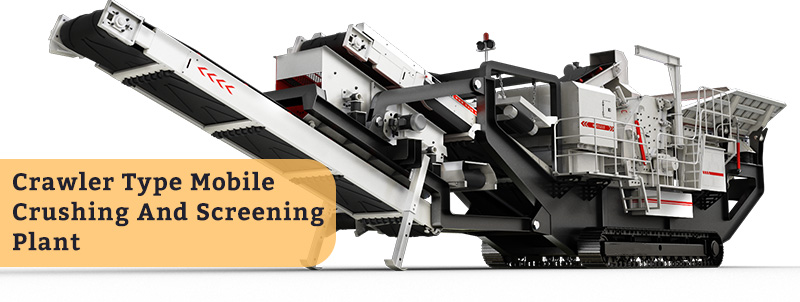

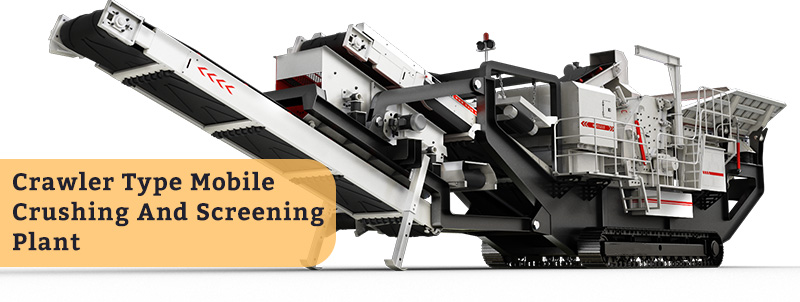

What is the crawler-type mobile crushing and screening plant?

Crawler-type mobile crushing and screening plant

Crawler-type mobile crushing and screening plant is a high-efficiency screening and crushing equipment. It adopts the self-driving method, advanced technology, and complete functions. The main design highlight is that it can reach any position on the work site and has high production. It can be applied in the fields of hydropower, highway, artificial sand and gravel, ore crushing, etc. It is more practical, especially for urban construction waste treatment.

Construction of crawler-type mobile crushing and screening plant

The crawler-type mobile crushing and screening plant is mainly composed of vibration feeders, crushers, such as jaw crusher (impact crusher or cone crusher ) crawler-type mobile crushing station, vibrating screens, etc.

Characteristics

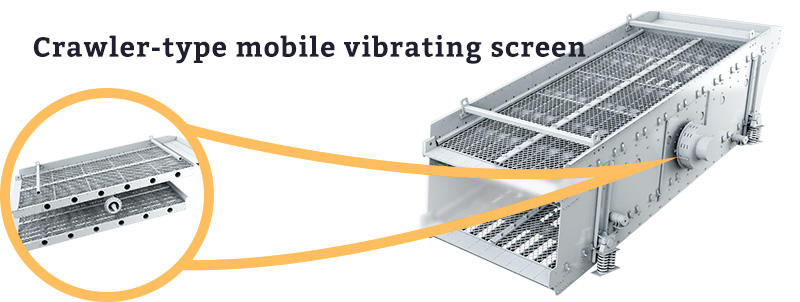

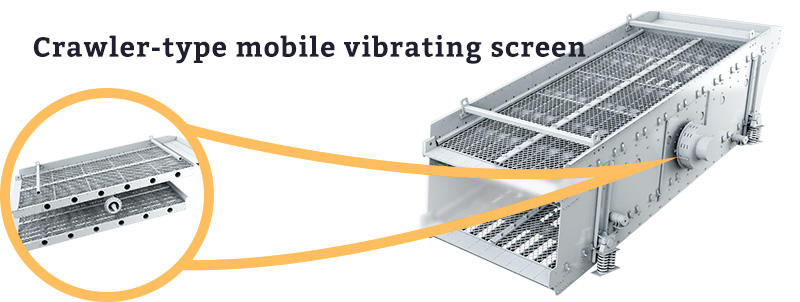

Crawler-type mobile crushing and screening plant, whose inclination angle of the screening surface is 18°, and the screening efficiency is high. The vibration exciter is made of eccentric shaft and eccentric block structure, which provides sufficient excitation force.

The oil is self-lubricating, and the lubricating oil is replaced once every 3-6 months. The key parts are designed with a wear-resistant rubber layer to extend the service life of the screening.

What is a gauge in reference to a screening plant?

Crawler-type mobile vibrating screen

Customers can choose from “screen first and then crush” or “break first and then sieve” to meet product requirements, or increase the return conveyors to achieve the conversion of closed circuit and open circuit, improving the usage of equipment.

The utility model combines with a common body and a model, a feeding unit exchange system and a screening unit interchange system, and the working efficiency and the production capacity are superior to the same level or the fixed screening station.

Crawler-type mobile crushing and screening plant integrates processing equipment such as receiving, screening and conveying and combines different models to form a powerful crushing and screening operation line. Its aim is to complete multi-demand processing work.

The design of the whole machine is completely in accordance with international road transportation standards, fully considering the convenience, high-quality driving components, uniform quality distribution, ensuring excellent driving performance, providing more flexible space for a reasonable layout.

Working principle

Screening plant 150t/h for Indonesia Customer of Constructional wastes recycling

The materials are conveyed to the crushing equipment through the belt conveyor, and the crushed materials are firstly sent to the belt conveyor then they are sent out, thirdly, through the transfer hopper, the materials are returned to the belt conveyor which is above the vibrating screen.

In addition, the materials are transported to the vibrating screen and are screened. The qualified materials are sent out by the hopper through the belt conveyor below the vibrating screen. The unqualified materials are directly sent back to the crushing to be broken again.

Achieve greater benefits for customers

1: high production capacity 45-500t/h

FTM crawler type mobile crushing and screening plant has high production capacity of 45-500t/h, by virtue of the following features:

——full series euro hosts

——most advanced crushing cavity

——high crushing ratio, low energy consumption

——reliable performance

——high running ratio

2: reliable performance

On the basis of more than 30 years manufacturing technology and experiences in mining machine industry, FTM Machinery adopts the precise design, high-level manufacturing and quality check system to ensure the smooth operation.Besides, FTM Machinery uses the high quality material to make easy-wearing parts of mobile screening plant, which are more durable and stronger.

crawler type mobile crushing and screening Plant ready to be delivered to Ghana

3: energy-conserving and environmental protection

most advanced engine system and high energy ratio, flexible running system makes the mobile crushing and screening plant work well and flexibly. Besides, there are professional dust and noise provention system.

4: safe operation

There is a proper platform for running. And being equipped with many kinds of safety and locking system, FTM mobile screening and crushing plants are working in a safe environment. More, the feeding and discharging mouths are able to be adjusted automatically with overload protection system inside the plant.

5: easy maintenance and overhual

The whole inner system of crawler type mobile screening and crushing plant is easy to be overhualed and checked, with automatic and hydraulic adjusting system, equipments for together lubrication, etc. For those easy-wearing parts, they are designed in the modules way, which is convenient for dismantling.

Crawler-type mobile crushing and screening plant can crush and classify the materials on the first line, significantly reducing the intermediate links and the material transportation expenses.

It has high production efficiency, the equipment can meet various requirements of customers for mobile crushing and screening, and the new type of equipment can be continuously operated. The equipment provides customers with finished products of excellent quality and comprehensive benefits.