What is a drum dryer machine?

The drum rotary dryer can also be called H series of rotary dryer. It’s an equipment for heating and drying materials, and the drum dryer design of sleeve structure can shorten the length of dryer. Since the heat dissipation area is greatly reduced, the heat consumption is reduced, and the doubled heat exchange area greatly improves the thermal efficiency. The drum dryer machine produced from China FTM has high mechanization degree, large production capacity, excellent structure, stable convenient operation. The rotary dryer capacity can reach 0.5-50t/h.

Drum dryer has a simple structure and is favored by the customers not only in industrial production but also in daily life. Different drum dryers with different sizes have different productivity and FTM Machinery can customize the product according to your needs. Rotary dryer is one high efficient drying machine with multi-usage. In addition, cylinder dryer has the typical advantages like wide range application, energy saving, environmental benefit and other advantages.

Fote Machinery rotary drum dryer is applied to dry materials in cement, mining, building materials, chemical industry, compound fertilizer production and other industries. Drum dryer parts are device, former and rear roller device, feeding and discharge device, conveying device, gear cover and so on.

Rotary drum dryer manufacturered from Henan Fote Mining Machinery Co., Ltd. is used to dry the material by transferring the material through the cylinder and configuring the feeding plate with animal material and high-temperature flue gas to exchange heat. It has characteristics of good drying effect, large production capacity, high operation rate, energy saving and environmental protection, easy operation and maintenance, and long service life of the whole machine and its parts like dryer drum belt. The multi-angle feeding device can greatly increase the heat exchange rate and shorten the drying time.

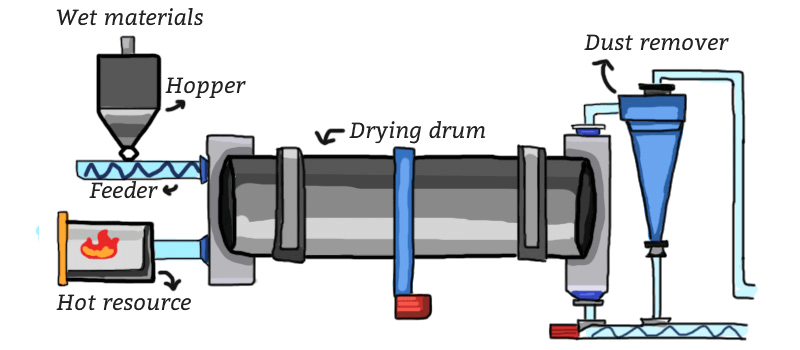

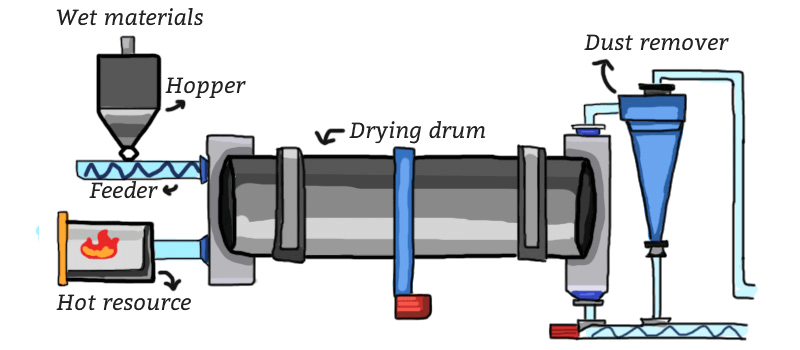

You can clearly see the internal structure of drum dryer

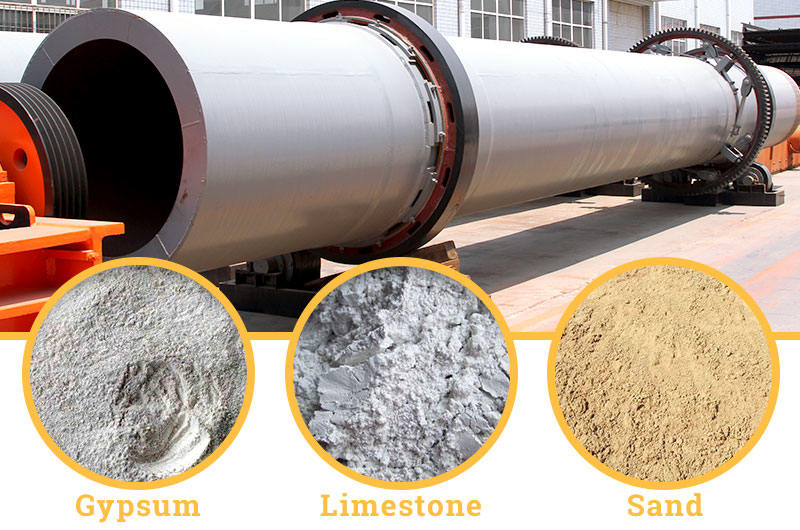

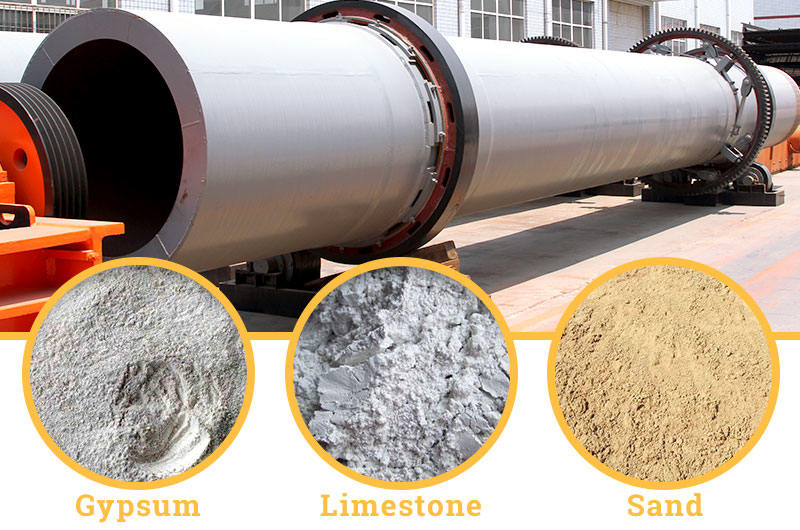

Applicable materials for drum dryer machine

Drum dryer is mainly used to dry block, powdered, paste type materials or materials with large water content. Cylinder dryer can dry materials like ore, sand, slag, coal, clay, sludge, coal slurry, hematite, copper, kaolin, slag, graphite, gypsum, ceramics, calcium carbonate, bauxite, tailings, etc.

Rotary drum dryer for sand, gypsum, limestone

Features of drum dryer equipment

The temperature of finished materials is less than 50℃ and they can be put into the feed library directly without cooling in the cooling shed.

The drum dryer is well sealed and the heat will not be emitted. You can install the drum dryer within 2 hours.

The traditional drum dryer has a thermal efficiency of only 32%. The new drum dryer’s thermal efficiency has been reached to 80%, which has improved by 48%.

It reduces the floor space by about 50% compared to the single-cylinder dryer, and the civil construction investment is reduced by about 50%.

The drum dryer can save 40% of electricity. Small rotary dryer annually can save coal 50-100 million, while large rotary dryer can save coal 1 million to 2 million.

The raw material is delivered smoothly through the cylinder, which improves the uniformity of material and increases its residence time. In addition, the efficiency of drum dryer has been improved a lot.

For materials with 30% initial water content, it can be dried to less than 1% through the drum dryer.

How does a rotary dryer work?

The material input into the drum dryer, it will contact the hot air flow and begin the drying process. The material is added from the higher end, the heat carrier enters from the lower end, countercurrent with the material. However, there is also a heat carrier and material that flow into the cylinder together. The wet material will directly or indirectly get the heat from the heat carrier and will be dryer finally. Then, the dried material will be output through the conveyor belt or screw conveyor.

The copy board equipped on the inner wall of the drum will constantly pick up the material, which will accelerate the heat exchange between hot gas and slag. Besides, a cleaning device is also provided to clean the resulting agglomerates and the material adhered to the wall in order to prevent clogging.

After the heat carrier passes through the dryer, it is generally required to collect the materials in the gas by a cyclone. If you want to further reduce the dust content of the exhaust gas, you should also discharge it after passing the bag filter or wet dust collector.

Rotary drum dryer working principle

Where can I buy a rotary dryer machine?

High-quality Drum dryer is the latest product developed by Fote Heavy Machinery with characteristics like stable operation, high adaptability, and large capacity. Both ends of the drum dryer adopt well-sealed cover which is not only environment benefit but also energy saving. Electricity consumption is 30% of the same type of product and coal consumption is 50% of the same type of product, and after being dried, the materials of drum dryer belt and drum dryer bearing all meet the national required standard. You can leave a message or send us an e-mail to get more information about the equipment. We will give a reply as soon as possible.

Fote heavy Machinery’s rotary drum dryer is for sale and the price is cheaper than manufacturers with the same quality machine. You can leave us a message or send us an e-mail to get more information about the equipment. We will give the reply as soon as possible. Thank you!

This is the rotary drum dryer production site that our customers feedback to us.