Brief introduction of sand dryer machine

FTM heavy machinery produces the three-drum dryer based on the original single-drum dryer, prolonging the pre-drying and drying time for wet material. Besides, it seals well, preserves heat, and equip reasonably. The production capacity of the sand dryer is 48-80% higher than that of the original single-cylinder dryer. The evaporation capacity per unit volume of sand dryer equipmemnt can reach 120-180kg/m3, and the standard coal consumption is only 6-8kg/t. The sand dryer machine has advanced technology, reasonable operating parameters, simple and feasible operation, and is widely used in slag, clay, and coal in various industries.

Bulk sand dryer 500lbs per hour production site

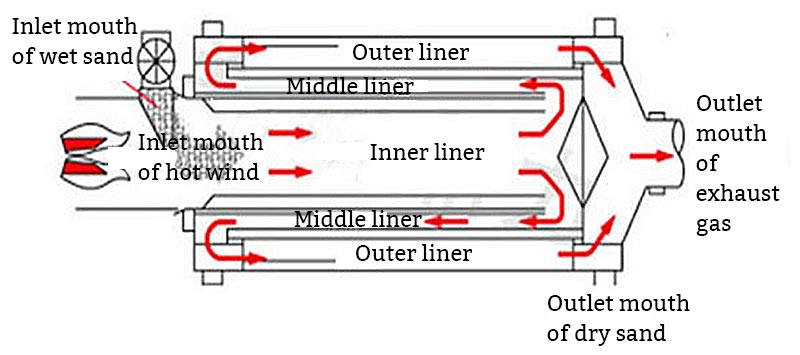

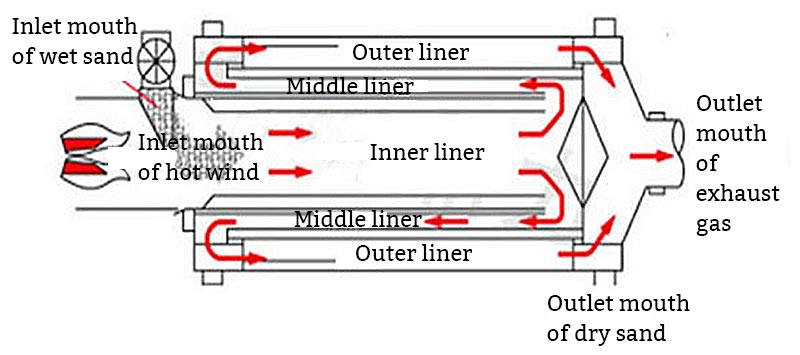

Structure of rotary three-drum dryer

The three-drum dryer is made up of three layers of sleeves: internal, middle and external one. Both the internal and middle drums are two-dimension ones and the external drum is a vertical one, which makes the most use of the sand drying drums. The three-drum dryer’s drum length is 25%-35% of the monocular dryer’s, thus decreasing the covering area of the sand dryer machine.

China Fote’s three-cylinder dryer is used to shorten the outer dimensions of the drying body by changing the single cylinder of the single-cylinder dryer into three cylinders that are stacked together. When the sand dryer machine is working, the material and the hot air flow are put from the inside to the outside. After the Z-shaped reciprocating, the hot air flow is used to dry the material and then discharged.

The drum part of sand dryer plant machine is composed of inner, middle and outer drums that are coaxially placed , which makes the cross section of the cylinder fully utilized. The overall length of the drum is about 30-35% of the single drum, thereby greatly reducing the floor space and plant floor area.

The supporting device of the plant machine is a wheel belt and a supporting wheel on the outer cylinder, and the motor directly drives the supporting wheel. The cylinder rotates through the friction between the roller and the wheel. The overall structure of the sand dryer machine is compact, reasonable and simple. In order to facilitate the repair and replacement of the wear parts, the middle part of rotary drum dryer is designed to be axially split and bolted to the joint.

Applied materials of sand dryer plants

The three-cylinder dryer(sand dryer equipment) manufactured by Fote Machinery is mainly used to dry granular materials in a certain humidity range, such as yellow sand used in the dry mortar industry, various sand with specifications for the foundry industry, blast furnace slag for building materials and cement industry, small particle size clay, small particle materials that do not change chemically, can resist high temperature in chemical industry.

The material entering the sand dryer is not stuck to the wall and the lifting plate. The temperature of the gas entering the sand dryer should not be higher than 750 degrees Celsius. If there is special requirement for high temperature drying, the inner tube and the lifting plate at the entrance of the dryer can be made of heat-resistant plates.

In addition, the three-drum dryer can handle iron powder, mineral powder and other mixed materials, as well as can dry fly ash, slag, sand, coal, iron powder, ore, blue carbon and other materials.

Sand dryer different types of materials

Advantages of sand dryer plant machine for sale

The FTM Machinery sand dryer is scientific, reasonable, efficient and energy saving. The inner tube hot air flow alternates in the form of radiation, convection, and conduction, and is exchanged in the outer tube for heat exchange for conduction and convection. The three-drum sand dryer has high thermal efficiency and remarkable energy-saving effect. After testing, the thermal efficiency greatly exceeds the level of 50% of the traditional dryer. After the sand dryer equipment is put into production, the coal saving effect is remarkable.

The sand dryer machine adopts the material and hot air flow downstream drying process, and has wide application. It can dry various raw materials such as clay, coal, slag, iron powder, etc. Sand dryer is also suitable for drying various bulk materials in metallurgy, chemical and other departments. It is placed horizontally, using the support wheel, canceling the large and small gear transmission.

The external surface area of the three-drum machine is 30% less than that of the single-cylinder rotary dryer. The outer cylinder can preserve temperature and reduce heat loss, which greatly improve labor environment and working conditions while saving energy.

According to the moisture and requirements on three drum rotary dryer capacity, the appropriate speed is used to ensure the next process can be continue. Automatic temperature monitoring system makes the operation easier.

One of advantages for the three-drum dryer

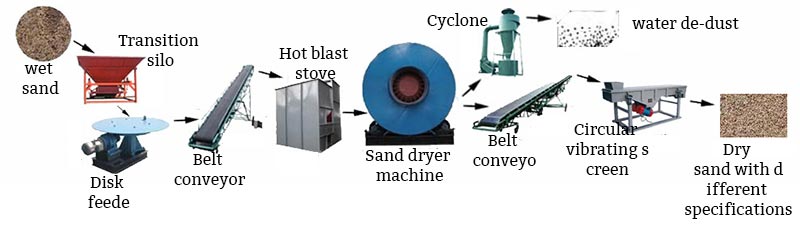

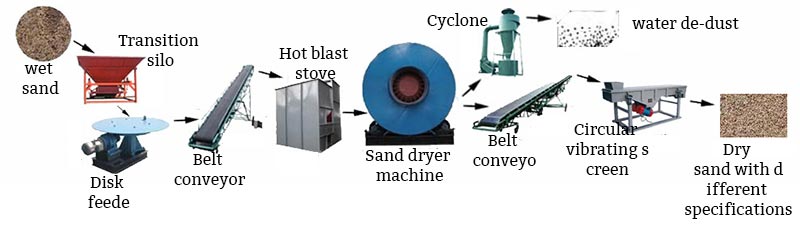

Working principle of portable sand dryers

During drying, the first-level drying zone (one return of the inner cylinder) uses downstream high-temperature for drying. Under high humidity conditions, the first-level drying zone in the inlet whose temperature is 430 ° C (up to 600 ° C) conducts heat transfer with the quart sand to remove most of the water and ensure that the heat value of the sand does not change.

The secondary drying zone (second return of the middle tube) adopts countercurrently dried way at room temperature of 300 ° C, and is a high-yield dewatering zone to make sure the sand being dewatered quickly.

The third-level drying zone (three rounds of the outer cylinder) is a normal drying zone whose the indoor temperature is 120 ° C-210 ° C. The main purpose of this level is to cool down the drying sand and quickly discharge the material, the process of which we called Flow drying. Through the above three operations, the heat value of the sand after drying is higher than that before the way it is, and finally the temperature of the discharged sand is 60-80 ° C with the moisture content within 0.8%, which truly plays the role of energy saving and consumption reduction.

Detailed working principle of three-drum dryer machine with high-efficiency

When the three-drum dryer is working, its drying drum rotates slowly with the inner cone drum filled with materials and hot air entering from the small end. Then materials flow to the middle drum and to the external drum successively. During this procedure, materials exchange heat with the hot air, thus realizing the drying purpose. As materials remain inside the drum for a long time, so the drying effect is perfect.

FTM Machinery’s sand dryer had been exported to many countries. We have professional technology team to make plan for you, and our after-service will provide you with site gudiance. If you have project and need our machine, please leave a message on our website.

The three-drum dryer is running

Customer story 1: 80 tons per hour sand dryer

80 tons per hour sand dryer machine belongs to a large-scale sand drying machine. The FTM-80 triple-pass drum sand dryer designed by our company has been put into market application. Users use it to dry sand below 60 mesh and with initial water content 8-10%. After drying, the finished sand with moisture content below 0.8% is used as dry powder mortar.

Specialized three-drum machine configuration for this customer by FTM engineer

| Name |

specification |

Motor |

Price |

Postscript |

| Silo |

3500mm*2500m;

board thickness δ5mm |

0 |

32000 |

Manufacturing on site |

| Disc feeder |

Motor Power:11kw |

11 |

32000 |

|

| Belt conveyors |

Model: B800X12m

10#Steel channel

Motor 11kw |

11 |

12000 |

Additional configuration |

Gas&coal

combustion

furnace |

Φ800mm X 2000mm;

11kw fan |

11 |

38500 |

Buy individually |

| Feed hood |

Feed hood Φ1850 |

0 |

4200 |

|

triple-pass drum

sand dryer |

Model:FTM-80

Specification: Φ

3200mm x

13000mmδ20/16/14mm;

Base: 2860mm x 2540mm

2sets

Motor: 15kw x 4 |

60 |

58000 |

Including base |

| Discharger |

Discharge silo Φ

1920mm |

0 |

4600 |

|

| Belt conveyors |

Model: B800 x 10m

10#Steel channel

Motor 7.5kw |

7.5 |

10000 |

Additional

configuration |

| Ventilation system |

draught fan: 75kw

Model: Y5-47-12D

Draft tube: Φ820mm x

15800mm |

75 |

42000 |

|

Dust collection

system |

Shakeron dust

collector 1500mm x 2+

Spray dust removal |

0 |

0 |

Not necessary |

Linear vibrating

screen |

1.8m x 4.8m 2sets

Power: 2 x 3.7kw |

7.4 |

88000 |

Not necessary |

Distribution

Cabinet |

supplementary |

0 |

8000 |

Not necessary |

| total price |

212.9 |

878400 |

|

Note:Equipment mentioned above include all kinds of electrical appliances.The feed silo can be purchased by yourself due to its large volume and inconvenient transportation. Whether to buy Shakeron dust collection, pulse dust removal and distribution cabinet depends on your own situation.

Customer story 2: 25 ton acid-washed quartz sand dryer configuration

Drying material: fine quartz sand;

Material granularity: 4-120 mesh;

Material condition: The moisture content is down to 10% after acid washing, deacidification and dehydration then it will be less than 1% after being drying.

Output: 25tph

Heat sources: gas

If you need output 25tph, processing capacity 27.5tph, moisture content from 10% down to less than1% , the amount of evaporated water 2500kg/h and hear requirement 1.5 million kilocalories, triple-pass drum sand dryer is the best choice. This sand dryer is designed to meet the output demand over 25 tons because its diameter is 2.0 meters and the length is 15 meters, the volume of the drying cylinder is about 47 cubic meters, and the evaporation volume per unit is 55KG.

FTM engineer is manufacturing high-quality three-drum dryer machine

Configuration: The heat source is natural gas which is clean and pollution-free. Both the dryer barrel and the parts in contact with the material are made of 304 stainless steel, which will not cause secondary pollution to quartz sand. Can reach the predetermined output, the highest output can reach 35 tons; This river sand dryer can reach predetermined output even higher to 35tons only if the initial water content range is below 15%.

Installation site of three-drum dryer machine

In order to save the production cost of sand dryer machine, it adopts the dryer cylinder made of 304 stainless steel with 10mm thickness, the lifting plate made of 304 stainless steel with 6mm thickness, and the feeding device made of 304 stainless steel with 8 + 10mm thickness. Because of no contact with material the front material cover uses Q235 Carbon steel while discharging opening hood adopts 304 stainless steel to ensure that the entire quartz sand drying process does not contact with carbon steel. So, it is estimated that the whole set of drying equipment uses net 304 stainless steel sheet about 9.78 tons

Loading site for three-drum dryer machine

The main board 10mm thickness needs ring lining widen to 500mm so that the dryer will be more stable during operation.The heat source is clean natural gas, so it can be equipped with a 1500 Shakeron dust collector only. After calculating, the whole river sand drying machine unit need carbon steel (including motor, reducer, draft fan, dust collector, pipeline, etc.): about 9.66 tons

FTM Machinery three-drum dryer machine will be shipped to our customer’s country

Three-Drum Dryer Technical Parameter

| Item/Unit/Model |

Φ2.5×7m |

Φ2.7×7m |

Φ3.0×7.0m |

Φ3.2×7.0m |

Φ3.6×8m |

| Cylinder volume( m³ ) |

16.63 |

16.63 |

52.678 |

52.678 |

81.38 |

| Initial moisture of slag(%) |

10-12 |

10-12 |

10-12 |

10-12 |

10-12 |

| Final moisture of slag(%) |

1 |

1 |

1 |

1 |

1 |

| Initial moisture of yellow ground(%) |

8-10 |

8-10 |

8-10 |

8-10 |

8-10 |

| Final moisture of yellow ground (%) |

0.5-1 |

0.5-1 |

0.5-1 |

0.5-1 |

0.5-1 |

| Highest intake air temperature(℃) |

700-750℃ |

700-750℃ |

700-750℃ |

700-750℃ |

700-750℃ |

| Production capacity(T/h) |

Yellow sand: 25-30

Slag: 20-25 |

Yellow sand: 30-35

Slag: 25-30 |

Yellow sand: 35-40

Slag: 30-35 |

Yellow sand: 45-50

Slag: 35-40 |

Yellow sand: 65-70

Slag: 60-65 |

| Motor power(kw) |

7.5×2 |

11×2 |

7.5×4 |

7.5×4 |

15×4 |

| Reducer type |

XWD7-23-11W |

XWD7-23-11W |

XWD6-23-7.5KW |

XWD6-23-7.5KW |

XWD8-23-15KW |

| Item/Unit/Model |

Cylinder volume( m³ ) |

Production capacity(T/h) |

| Φ2.5×7m |

16.63 |

Yellow sand: 25-30

Slag: 20-25 |

| Φ2.7×7m |

16.63 |

Yellow sand: 30-35

Slag: 25-30 |

| Φ3.0×7.0m |

52.678 |

Yellow sand: 35-40

Slag: 30-35 |

| Φ3.2×7.0m |

52.678 |

Yellow sand: 45-50

Slag: 35-40 |

| Φ3.6×8m |

81.38 |

Yellow sand: 65-70

Slag: 60-65 |