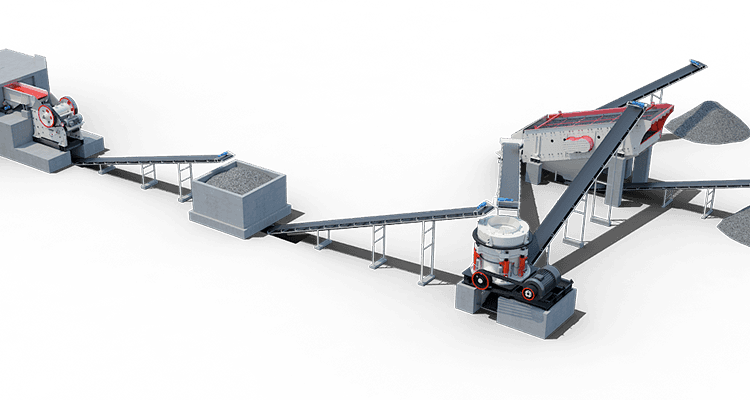

Raw material: ore

Feeding size: ≤400 mm

Output size: 0-5, 5-40, 40-70 mm

Recommended main equipment: GZD-1000×3600 vibrating feeder, PE600x750 jaw crusher, PF-1315 impact crusher, 3YK1548 vibrating screen

10-500t/hProduction Capacity

10-50t/h,100-200t/hHot

Raw Materials Processing: limestone, quartz stone, marble, granite, ore, slag, pebbles, etc.

First, the stone material is evenly fed into the primary crusher by the feeder for preliminary crushing. Then, the coarse material produced is sent to the impact crusher by the conveyor for further crushing. The finely crushed stone enters the vibrating screen to screen out stones of different specifications.

For uniform feeding

For coarse crushing

For secondary crushing

For secondary crushing

For screening grading

Stone crushing production line is equipped with dust removal system,dust suppression system, spray noise reduction system.

The combination of primary and secondary crushing equipment forms an advanced production line.

Adopt PLC control system to achieve precise control.

It meets the national standards for building sand and stone.

24/7 online service

Customize solution for free

Free training and installation

Fast accessory services

Timely technical support