As we all know, the road construction and building materials often need sand production line, and FTM machinery(which also calls Fote company) sand production equipment can meet the requirements of stone and artificial sand production.

Sand making machine youtube video

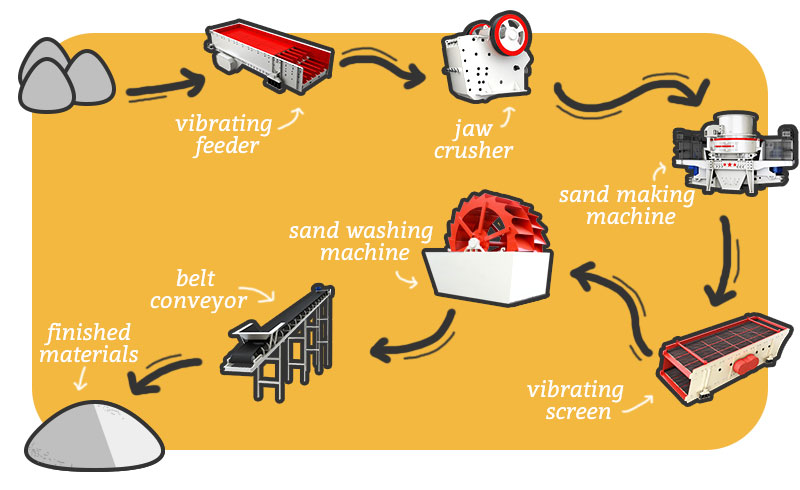

The sand production line is usually composed of vibrating feeder, jaw crusher, sand making machine, vibrating screen, sand washing machine, belt conveyor, centralized electric control, etc.

A company has made an inspection of crushing equipment in China for nearly half a year, and finally attracted by FTM heavy machinery’s strong processing capability and sophisticated technology, A has purchased a 500T/H gravel aggregate production line. At present, the equipment has been installed and commissioned, and the output and grain type are all meeting customer’s requirement.

Up to now, this production line has also become a new model project of FTM in Kazakhstan. The output is generally 50-500T/H. FTM heavy machinery has experienced several years of development research, and it makes the sand making machine match with other series of products, whose aim is to design a complete sand production line. And in this way, FTM company is deeply loved by users in the industry.

Fote heavy machinery is engaged in the research and production of sand and stone crushing for many years. Its sand making production line and ordinary sand making production line are designed according to the situation in China, they have the following characteristics:

Characteristics of sand and stone production line

What’s more, during the process of the sand production line, due to the reasonable match of sandstone equipment at all levels and the rigorous cross layout of space, the FTM Machinery sand production line has the small occupation, high benefit of economic investment, good quality of crushed stone, and low output rate of stone powder.

Working process of sand production plant

Firstly, the stone material is evenly sent to the jaw crusher for rough breaking by the vibrating feeder. The coarse material is sent to the impact crusher for second crushing. Secondly, the crushed material is sent into the vibration screen by the belt conveyor. The stone which meets the feeding particle size of the sand machine is sent to be made sand, The stone that does not meet the requirement is re-crushed.

Besides, the stone from the sand machine is entering into the vibrating screen for screening again. The process doesn’t stop until the sand meets the requirement. Then the sand is sent into the sand washing machine for cleaning. After cleaning, it is transported by the finished conveyor belt, which is the finished product.

Finally, the unqualified sand and gravel mixture is sent to the sand making machine for crushing again. The production line finally forms a two-stage closed loop.

FTM machinery provides customers with free production lines. We can go to your site to analyze the actual situation and customize the production line for you. Fote company has the following main production lines:

Indonesian river pebble sand production line site, Hubei limestone sand production line site, artificial sand making machine in india, and Philippines sandstone sand washing production line site.

Sand production line site

If you are owner of a pebble mine, granite mine or quartz quarry, what kind of machines you use on a VSI sand making plant? Based on 50 year experience, FTM Machinery introduces the common configurations below for you to consider.

1: sand making plant from pebble stone, with capacity of 50-70t/h

configuration: vibrating feeder + 2 PEX jaw crusher + sand making machine + vibrating screen + sand washer + belt conveyor

2: artificial sand making plant from granite stone, with capacity of 80-130t/h

configuration: vibrating feeder + 2 PE jaw crusher + vibrating screen + cone crusher + sand making machine + sand washer + belt conveyor

3: artificial sand manufacturing plant from quartz stone, with capacity of 60-80t/h

configuration: raw material bin + vibrating feeder + jaw crusher + impact crusher + sand making machine + vibrating screen + sand washer + belt conveyor

4: sand making plant for sale to process limestone with capacity of 100-150t/h

configuration: raw material bin + vibrating feeder + jaw crusher + impact crusher + sand making machine + vibrating screen

Contact

E-mail:vip@sinoftm.com

Address: Tanxiang Road, High-Tech Industrial Development Zone of Zhengzhou City, P. R. China.

Hot Products

Leave your personal information(Only kept by FTM), for sending a favorable price meets your production budget.

Inquiry Online 7×24 Online