Welcome to the photo gallery of our products, then you will find the lightspot of various equipment, and enjoy yourself !

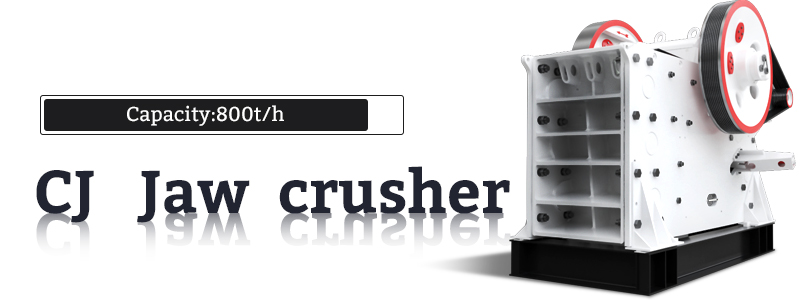

The Fote Machinery jaw crusher has appeared for a long time. Based on the primary jaw crusher, FTM company,jaw crusher manufacturer, introduced the advantaged technology from western countries and produced different types of jaw crushers, such as the CJ jaw crusher. It has great improvement in the terms of motion parameters, structural form, adjustment method.

The raw material can be crushed in the upper of the crushing chamber. The bigger stroke at the bottom of the crushing chamber, the larger broken ratio CJ jaw crusher is. The CJ Jaw crusher machine and motor are integrated together, which occupies small space.

The machine discharge port adopts wedge adjustment mode to reduce downtime and reduce labor intensity. Customers can set different sizes of discharge port according to the raw materials. The single CJ jaw crusher can process materials for 800TPH. Our CJ jaw crusher had been for sale in USA, UK, Canada, and the Philippines. Here are some CJ jaw crusher pictures:

CJ jaw crusher

There are two kinds of mobile rock crushers. They are tire-type mobile crusher and tracked mobile crusher. There are higher requirements on the rock crusher machine, Henan Fote Machinery Ltd.create a new kind of crusher—–mobile crusher equipment. It can directly work on the front line, reduce the transportation of raw materials and is environmental-friendly.

Since the advantages of compact and reasonable structure, the compact mobile rock crusher is easy to transfer from the production site. Fote can equip with the screen for the mobile crusher according to customer’s request. 40 years of mine production technology experience allow the Fote Machinery to produce a mobile crusher with simple, reasonable and compact structure.

Tire-type mobile crusher and tracted mobile crusher

The impact crushers play the important role in the crushing line. Impact crusher adopts a unique structural design, and the finished product is cubic. The grain shape is quite good and no tension and cracks. Besides, it can crush all kinds, of course, medium and fine materials (granite, limestone, concrete)whose feed particle size doesn’t exceed 500mm and compressive strength doesn’t exceed 350MPa.

Its maximum processing capacity up to 800TPH. The hammer made of high chromium is anti-Impact and anti-war. The rotor has a strong moment of inertia. Its feed inlet is large, and the crushing chamber is high. It can process raw material with high hardness. The finished products have less dust and good grain type.

The Characteristic of impact crusher

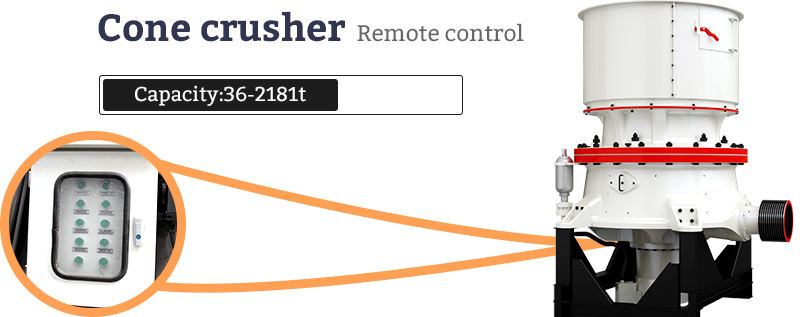

All parts of the FTM Machinery hydraulic cone crushers are protected by wear-resistant materials, which can increase the service life by more than 30%. The device is delayed for 120s after boot. Then, the lubricating oil will be a field with the entire host equipment within 120s, which effectively reduces the wear and tear of the equipment during operation.

Customers can set the different inlet and outlet sizes with one button, which can be accurate to the millimeter. If there is an emergency at work, the cone crushers will shut down the host immediately. What is most important is that hydraulic cone crusher can be controlled in a distance. If you have problems on the machine, our technical manager can help you solve as long as you insert a phone card into the cone crusher control terminal.

PLC for the cone crusher

The cone crusher, manufactured by FTM company, can be used for medium crushing, fine crushing, and super fine crushing. The upgrade of speed and stroke make the cone crusher possible to improve its breaking ratio and production efficiency.

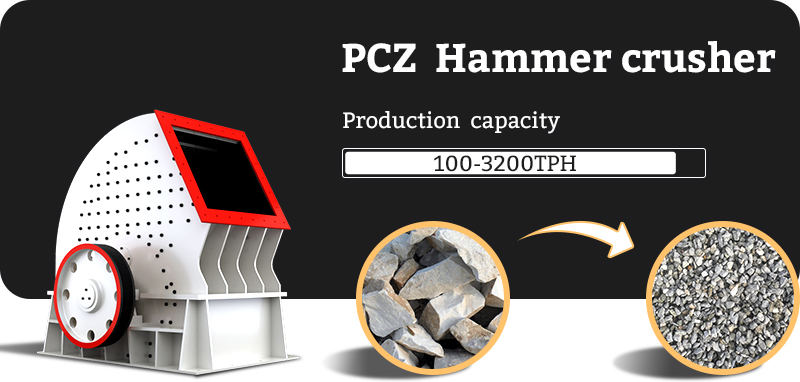

With the development of infrastructure, the stone market is very hot. R & D personnel in Henan Fote Machinery Ltd. independently developed the PCZ heavy hammer crusher based on the needs of users and characteristics of materials.

It can process raw material 100-3200TPH. It’s a new kind of rock crusher which combines hammer crusher with impact crusher. It can crush the raw materials into well-formed products directly, which reduces costs about 40%. Sieve design, reduce dust, low noise, grain shape. The heavy hammer crusher is designed modularly so that you can get different size of finished raw materials by changing the different cavity. It sold well in India, Indonesia, Brazil, Nigeria, etc.

PCZ heavy hammer crusher

Fote Mining Machinery’s whole sandstone crushing plant provides you with comprehensive technical support. The configured gravel crushing production lines are carefully designed for customers according to the on-site site survey or actual requirements of customers, which fully reflects the rationality, effectiveness and applicability of design. The strong technical strength and perfect service system of FTM Company machines are the guarantee for customers to purchase and use with confidence. According to different process requirements, various types of equipment are combined to meet different process requirements of customers. If you have needs, welcome to our company for a visit and consulting.

Sandstome crushing production site

Roll crusher which is also called double roll crusher is suitable for medium and fine crushing of materials smaller than 150mm in cement, chemical, electric power, mining, metallurgy, building materials, refractory materials, coal mines like coal, coal gangue, coke, limestone, iron ore, quartz stone, sulfur ore, etc. The crushed material is usually brittle, the compressive strength does not exceed 160Mpa, and the water content does not exceed 6%, otherwise particle bonding will occur.

Contact

E-mail:vip@sinoftm.com

Address: No.168 Wutong Street, High-Tech Industrial Development Zone of Zhengzhou City, China.

Hot Products

Future Prospect

We would like to cooperate with customers all around the world, and welcome you sincerely !

Inquiry Online 7×24 Online