Stone crusher is a mechanical equipment used to break stones, ores and other materials into specified sizes. It is widely used in mining, construction engineering, chemical industry, metallurgy and other industries. We have small, medium and large stone crushers. Different models can meet your different needs.

The materials that the stone crusher can crush include: granite, basalt, limestone, marble, river pebbles, cobbles, bluestone, gangue, dolomite, calcite, quartzite, tailings and more than 100 kinds of soft and hard stones and rocks.

Common models of stone crushers include: jaw crusher, impact crusher, cone crusher, impact crusher,hammer crusher, ect.

-

-

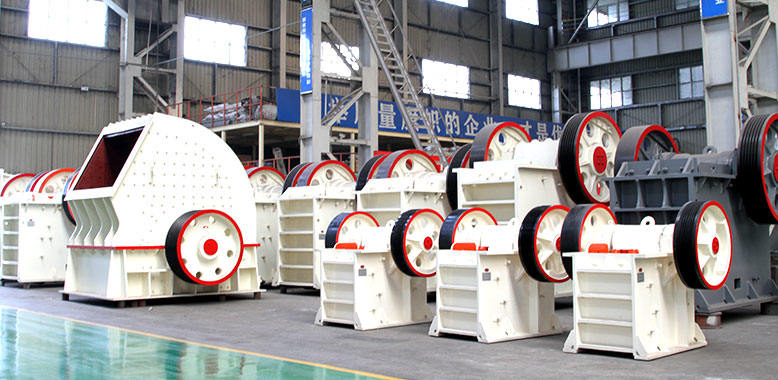

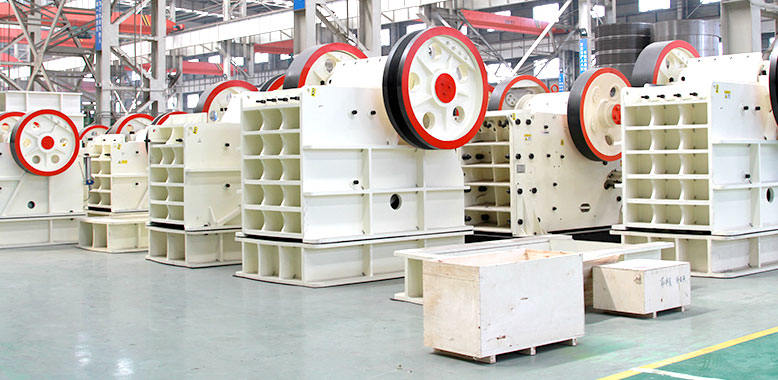

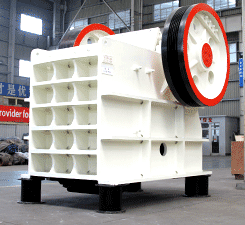

Jaw Crusher— The jaw crusher mainly crushes the material under the function of extrusion between two jaws.

-

-

Impact crusher— The impact crusher adopts the principle of impact crushing, and the material is repeatedly crushed and broken between the rotor, hammer, and counterattack.

-

-

Cone crusher—Cone crusher uses the lamination principle to break the stone. Rolling wall movies to the broken wall constantly to extrude the stone materials between them.

Fixed jaw crusher can process all kinds of soft stones, but impact crusher is suitable for crushing the stone materials with small toughness and medium hardness or bellow, such as the limestone.Depending on the crushing materials, discharge size, output, ect. there will be a cost-effective stone crusher to meet your needs.

Stone crusher cases

Jaw crusher plant case: Its main material is the aggregates, and the finished products of the jaw crusher machines are used for local hydropower infrastructure construction. The three-stage project includes the jaw crusher, cone crusher and sand maker to process the pebble, among which the jaw crusher is used for the primary machine. The aggregates can be crushed into the medium granularity one time.

Jaw crusher working site

Stone Crusher Plant: At first, the stone materials are delivered into the jaw crusher for coarse crushing by the feeder. Then, the materials crushed by the jaw crusher will be crushed by impact crusher or cone crusher further. Thirdly, the crushed stone materials are sent to the vibrating screen to separate the stone materials from the impact crusher or cone crusher.

Stone crusher plant

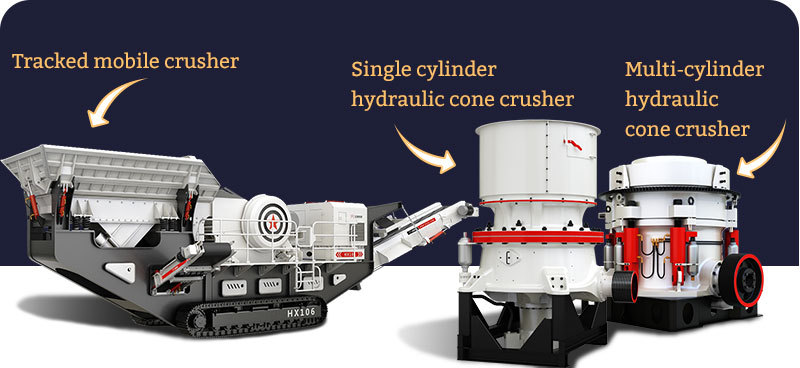

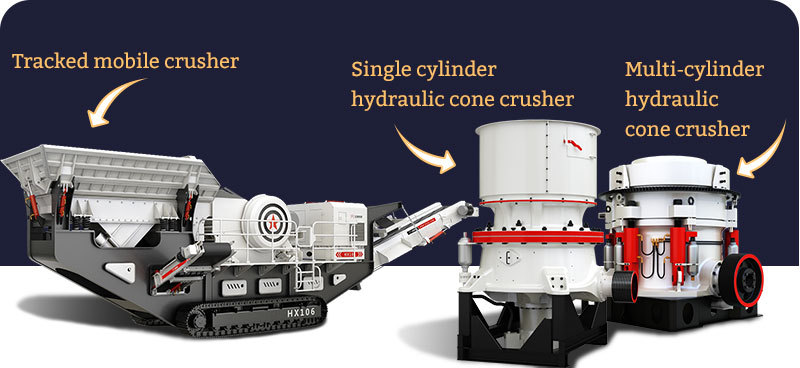

Other new types of stone crushers

We not only have the HD jaw crusher, but also have the portable jaw crusher, mobile impact crusher, mobile cone crusher. With the development of Henan Fote Machinery Ltd. and the creation of crushing technology, more and more new type crushers arise, such as single cylinder hydraulic cone crusher, multi-cylinder hydraulic cone crusher, and tracked mobile crusher.

New types of mining crushers

Customers should analyze and compare with different situations when choosing the crusher machines. For example, a large-scale company often use cone crusher for their beneficiation project, while the impact crusher is suitable for the medium and small beneficiation factories.

If you want to process the viscous material, the jaw crusher and impact crusher are the better choices. It is suggested that you can choose the most economic crusher based on your comprehensive demands and site situation with the help of FTM Machinery engineers.

Stone Crusher Technical Parameter

| Model |

Max.Feeding size (mm) |

Adjustment range of discharge port (mm) |

Capacity(t/h) |

Power (kw) |

Dimensions(L×W×H) (mm) |

| PE 250×400 |

210 |

20-70 |

5-21 |

6P 15 |

1100×1032×1285 |

| PE 400×600 |

340 |

40-100 |

16-64 |

6P 30 |

1623×1736×1615 |

| PE 500×750 |

425 |

50-100 |

40-110 |

6P 55 |

1920×1850×1920 |

| PE 600×750 |

500 |

150-200 |

80-240 |

6P 55 |

2020×1850×1920 |

| PE 600×900 |

500 |

65-160 |

50-160 |

6P 55 |

2530×1900×2340 |

| PE 750×1060 |

630 |

80-180 |

110-320 |

8P 110 |

2680×2380×2785 |

| PE 900×1200 |

750 |

100-200 |

220-380 |

8P 110 |

3470×2876×3330 |

| PE1200×1500 |

1020 |

150-350 |

400-1000 |

8P 160-245 |

4850×3220×3680 |

| PE1500×1800 |

1200 |

220-350 |

500-1200 |

8P 280-380 |

5160×3660×4248 |

| PEX 250×1000 |

210 |

25-60 |

16-52 |

6P 30 |

1580×2006×1390 |

| PEX 250×1200 |

210 |

25-60 |

20-61 |

6P 37 |

1780×2214×1430 |

| PEX 300×1300 |

250 |

20-90 |

16-105 |

6P 55 |

2210×2320×1723 |

Note:processing Capacity May Vary With Different Materials And Feeding Sizes.

| Model |

Max.Feeding size (mm) |

Capacity (t/h) |

| PE 250×400 |

210 |

5-21 |

| PE 400×600 |

340 |

16-64 |

| PE 500×750 |

425 |

40-110 |

| PE 600×750 |

500 |

80-240 |

| PE 600×900 |

500 |

50-160 |

| PE 750×1060 |

630 |

110-320 |

| PE 900×1200 |

750 |

220-380 |

| PE 1200×1500 |

1020 |

400-1000 |

| PE 1500×1800 |

1200 |

500-1200 |

| PEX 250×1200 |

210 |

20-61 |

| PEX 300×1300 |

250 |

16-105 |

Note:processing Capacity May Vary With Different Materials And Feeding Sizes.