FTM new generation of grinding plant is a large-scale production line, and it can make stone become an ultra-fine powder used in many fields of production industries.

The grinding plant

The grinding plant of FTM machinery mainly processes diabase, activated carbon, ceramics, limestone, calcite, dolomite, barite, talc, gypsum and so on. The stone mill can grind stones into powder or ultra-fine powder for industrial construction, chemical engineering, refractory materials, and metallurgy.

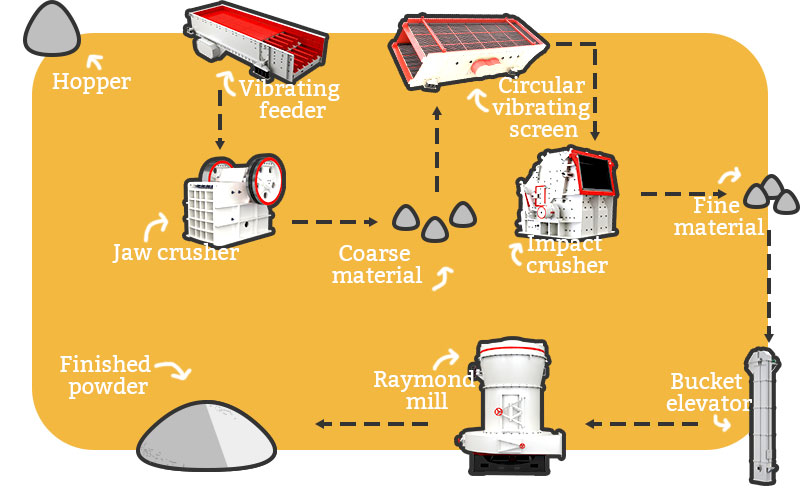

The FTM grinding plant can produce 20-1,000 mesh stone powder. The whole machine is composed of the main machine (Raymond mill), pipeline device, air blower, jaw crusher, bucket elevator, hopper, vibrating feeder, power distribution cabinet and so on.

The grinding plant of FTM heavy machinery can be equipped with the following mills: Raymond mill, high-pressure ultrafine mill, and triple-ring mill with medium speed.

host mills

Firstly, when the bulk material is crushed to the required particle size by the jaw crusher, then the material is sent to the silo by the hoist, and the vibrating feeder sends the material evenly and continuously into the host grinding chamber, such as FTM HGM Raymond mill, the powder after being ground is taken away by the fan airflow and is classified by the analyzer. The fine powder which meets the requirement can enter the large cyclone collector for separation and collection, and finally, they are discharged through the discharging pipe. So the product powder is finished.

Working process

The design of the grinding roller is novel and the material selection is reasonable, it is more reliable, and the pressure on the processing material is increased by 15%-20%.

The rate of changing bearing replacements is small, the service cycle is long, and the life of the whole machine is extended by 3-5 times compared with other mills.

FTM grinding plant has high efficiency, fast operation, precise control of discharging fineness and the selector can be frequently controlled.

Under the condition of uniformity of fineness and output, the energy consumption of the body is only 1/3 of the airflow grinding, saving oil and electricity costs of 30,000 yuan per year.

FTM grinding plant is installed with a new type of high-efficiency pulse dust-removal equipment, and it is also equipped with a silencer to eliminate dust, noise, and other pollution, so that FTM heavy machinery can establish a green production workshop.

Under the same capacity and fineness, FTM grinding plant whose price is 80% cheaper than the airflow mill.

The company mainly has quartz stone grinding, barite, and limestone plant.

Different application fields: Raymond mill is suitable for stone milling, and ball mill is used for ore dressing.

Different grinding media: Raymond mill mainly grinds non-metallic ore, which can not be applied to grind metal ore, and materials ground with water content is greater than 6%. However, ball mills can be used to grind metal ore.

The fineness and output of finished product are different: the particle size of the polished product is finer and more uniform, but the output is relatively less, and the finished product of the ball mill is more than that one.

FTM manufacturer is focusing on the grinding line for more than 30 years, and it has become famous in the industry and has a very good market reputation.

Before the sale, FTM machinery combines with the working site situation, tailor-made, and recommends the appropriate equipment model for customers, What’s more, the company configures the scientific production line, and answers any questions of the customer in time.

During the sale, the company can make an inspection of the grinding equipment, strictly eliminate the mistakes and sign a formal purchase contract with the customer.

After the sale, the company would arrange the technicians to install and debug the equipment on site, and stay on the site until the equipment is working normally for one week. At the same time, it is responsible for the maintenance and repair of the equipment.

FTM machinery grinding line for customers is advanced in structure, stable in performance, and affordable in service. Welcome friends to consult and purchase, or visit our factory for inspection and free test machine!

Contact

E-mail:vip@sinoftm.com

Address: Tanxiang Road, High-Tech Industrial Development Zone of Zhengzhou City, P. R. China.

Hot Products

Leave your personal information(Only kept by FTM), for sending a favorable price meets your production budget.

Inquiry Online 7×24 Online