Conveyor belt definition

Conveyor belt is an essentical equipment in the mining production line. It seems that it doesn’t play an important role, but the mining production line will be stoped withou the conveyor belt. The conveyor belt is used to diliver all kinds of solid block and powder materials in the industry of agriculture, industrial and mining enterprises and transportation.

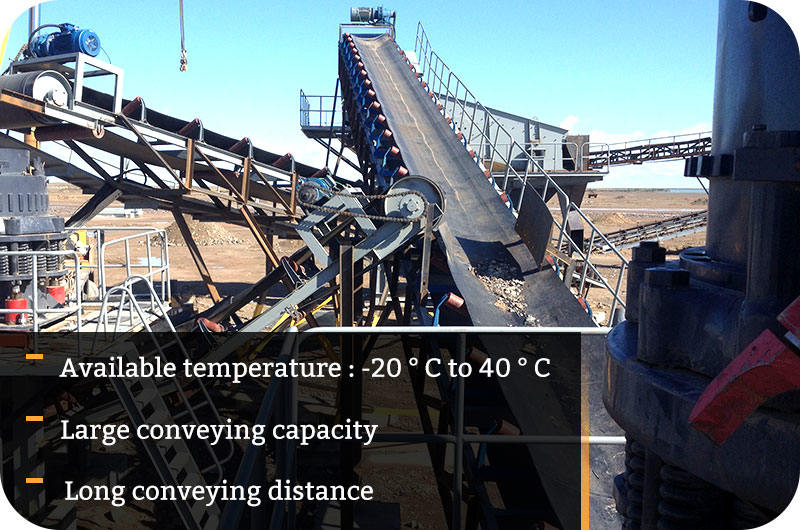

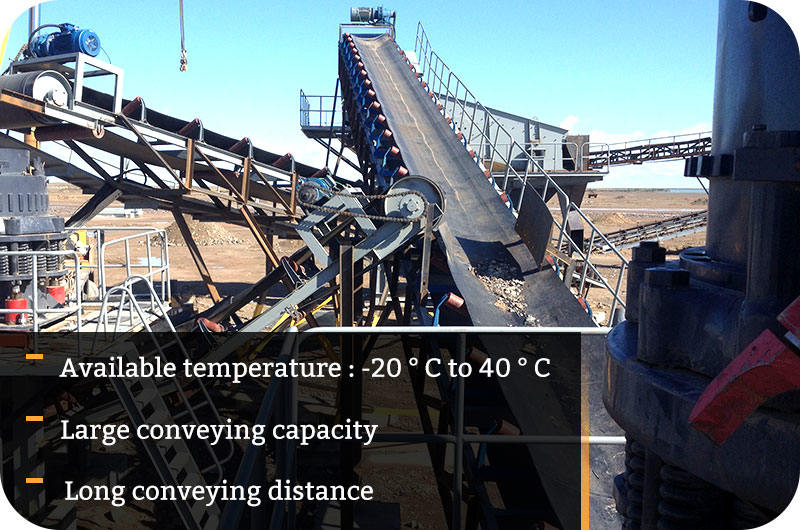

Conveyor belt can deliver the materials horizontally and obliquely, which is easy to use and widely used in many morden industries, such as underground roadway, mine ground transportation system, open pit mining and concentrating plant. According to different process demands, customers can use one conveyor belt and more conveyor belts to deliver the materials.

For mining industry, the conveyor belt is the necessary for all mining process and the applications of the conveyor can be used for many materials. Besides, it can be customed, which means the lenghth and sizes are different in terms of differernt modulars. ccording the different structures of convryor belts, FTM Machinery manufacturered many types of belt conveyor, such as flat belt conveyor, climbing belt conveyor, roll belt conveyor, turning belt conveyor, etc.

Conveyor belt

The structure of convryor belt

Conveyor belt system consists of head frame, drive unit, drive roller, tailstock, idler, intermediate frame, tail redirection device, unloading device, cleaning device, safety protection device, ect. The body of conveyor belt is made of high quality steel plates. The frame is formed by the height difference of the front and rear legs, and the plane is inclined at an angle.

The conveyor belt rollers installed on the body of conveyor belt are used to drive and support conveyor belt. There are two kinds of conveyor belt motors, one is the geared motor and another is the electric drum motor.

Features of conveyor belt

1.The material has a large accumulation area on the conveyor. And it has high belt speed and large conveying capacity.

2.There is no relative motion between raw materials and conveyor belt. Less noise, simple structure, convenient maintenance, less energy consumption, standardization of components, etc.

3.It drives under the principle of friction, and has the advantsges of large conveying capacity, long conveying distance and stable transportation. You can add raw materials when it is working and will not go wrong and scatter from the conveyor belt.

4.It has wide application range. It can be used to deliver raw materials in the production of mining, metallurgy, chemical, foundry, and building materials. Besides, hydropower station construction site and port and other production departments also need the conveyor belt.

5.The belt conveyor can be used in the range of ambient temperature -20 ° C to 40 ° C, and the temperature of the transport material is below 50 ° C.

Features of conveyor belt

Working principle of conveyor belt

The conveyor belt forms an endless belt with a drive roller and a tail roller. The upper and lower parts of the conveyor belt are supported on idlers. The tensioning device provides the tensioning force its for the normal operation. When working, the driving drum drives the portable conveyor belt through the friction between tensioning device and the belt.

Raw materials are loaded from the loading point, forming a continuous motion logistics, and will be unloaded at the unloading point. General materials are loaded onto the upper belt (load section) and unloaded in the head drum (here is the transmission drum). Special unloading devices can also be used to unload in the middle.

Working principle

Conveyor belt for sale

The belt is the expensive and wearable part of conveyor belt. Therefore, you should smaitain and regularly inspect and test the equipment if it has finished the work. The conveyor belt manufacturered from Fote company is for sale. The price of conveyor belt is cheaper than other manufacturers in China.

FTM Machinery can provide you with convryor belt of several sizes