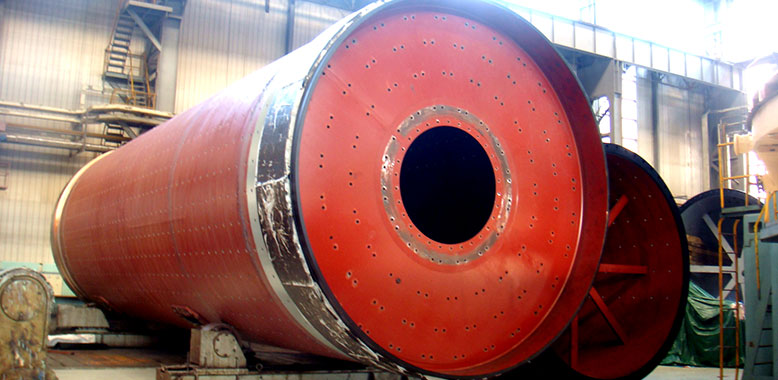

Raw material mill is used for processing and grinding different kinds of cement materials, cement clinker, silicate products, cement, limestone, building material, metallurgical material, and others powders used for electricity and chemical engineering, etc. It integrates the drying work and grinding work together. Also, raw material mill machine can be used to grind clay, etc.

Raw material mill is grinding cement now

Raw material mill uses large caps, end caps and hollow shaft for the whole cast, and the feed system uses a unique streamlined design, reducing ventilation resistance, increasing the effective volume and increasing mill production. Raw material grinding mill has single-silo structure and mill liner, which can grind materials for different stages in different liner structure, greatly improving grinding efficiency.

Raw material grinding machine’s working pressure is negative pressure, effectively preventing the occurrence of leakage. Dry-hot wind for high temperature kiln exhausts gases into the wind, and the grinding process is undertaking in insulation.

Raw material mill usually uses edge driving way, materials are continuous and uniformly sent to the raw material mill by feeding machine, and the motor of reducer leads the tube body of raw material grinding mill to rotate. Materials firstly enter into the first grinding warehouse along hollow axis, be crushed by steel balls in tube body. Final products with qualified size will be discharged from the raw material grinding machine; while unqualified products will go back into the raw material mill for grinding again, until their fineness is qualified.

1. Common raw material mill is suitable for medium and small scale, commonly used for grinding out selected powder-circuit grinding systems.

2. Air swept mill. Its features are short and rough, and the wind speed of grinding warehouse can be up to 5m/s, so hot air can enter into it, thus it’s with strong drying capacity.

1: wide application ranges, as mentioned above, it can grind almost of powders used for chemical engineering, metallurgy, building material, etc

2: easy to operate and high capacity, reaching to 135t/h

3: little production and high rate powder making

4: durable and easy maintenance

5: low grinding cost

Product specification

(m) |

Milling form |

Production capacity

(t/h) |

| Φ1.5×5.7 |

Open flow |

4.5-6 |

| Φ1.8×6.4 |

Open flow |

7.5-15 |

| Φ2.2×6.5 |

Circle flow |

14-26 |

| Φ2.4×7 |

Circle flow |

24-28 |

| Φ2.4×10 |

Circle flow |

32-36 |

| Φ2.6×10 |

Circle flow |

45-50 |

| Φ3×9 |

Open flow |

55-60 |

| Φ3.2×9 |

Circle flow |

62-65 |

| Φ3.5×10 |

Open flow |

70-75 |

| Φ3.8×7.5 |

Circle flow |

80 |

| Φ4.6×10+3.5 |

Circle flow |

190 |

| Φ4.6×10.5+3.5 |

Circle flow |

210 |

Raw Material Mill Technical Parameter

Product specification

(m) |

Milling form |

Transmission form |

Gear box |

Motor power

(kw) |

Production capacity

(t/h) |

Total weight

(t) |

| Model |

Speed reduction ratio |

| Φ1.5×5.7 |

Open flow |

Brim |

ZD40 |

3.55 |

130 |

4.5-6 |

25.8 |

| Φ1.8×6.4 |

Open flow |

Brim |

ZD60 |

4.5 |

210 |

7.5-15 |

43 |

| Φ2.2×6.5 |

Circle flow |

Brim |

ZD70 |

5 |

380 |

14-26 |

60 |

| Φ2.4×7 |

Circle flow |

Brim |

ZD70 |

5 |

475 |

24-28 |

81 |

| Φ2.4×10 |

Circle flow |

Brim |

ZD80-4-LL |

6.44 |

570 |

32-36 |

118 |

| Φ2.6×10 |

Circle flow |

Brim |

JDX710 |

6.3 |

800 |

45-50 |

130 |

| Φ3×9 |

Open flow |

Brim |

JDX800 |

6.3 |

1000 |

55-60 |

158 |

| Φ3.2×9 |

Circle flow |

Brim |

MBY900 |

7.1 |

1250 |

62-65 |

195 |

| Φ3.5×10 |

Open flow |

Brim |

JDX900 |

5.84 |

1250 |

70-75 |

200 |

| Φ3.8×7.5 |

Circle flow |

Brim |

JDX900 |

5.6 |

1600 |

80 |

233 |

| Φ4.6×10+3.5 |

Circle flow |

Central shaft |

JQS3550 |

15.1 |

3550 |

190 |

415 |

| Φ4.6×10.5+3.5 |

Circle flow |

Central shaft |

JQS3550 |

15.1 |

3550 |

210 |

476 |

Product specification

(m) |

Milling form |

Transmission form |

Gear box |

Motor power

(kw) |

Production capacity

(t/h) |

Total weight

(t) |

| Model |

Speed reduction ratio |

| Φ1.5×5.7 |

Open flow |

Brim |

ZD40 |

3.55 |

130 |

4.5-6 |

25.8 |

| Φ1.8×6.4 |

Open flow |

Brim |

ZD60 |

4.5 |

210 |

7.5-15 |

43 |

| Φ2.2×6.5 |

Circle flow |

Brim |

ZD70 |

5 |

380 |

14-26 |

60 |

| Φ2.4×7 |

Circle flow |

Brim |

ZD70 |

5 |

475 |

24-28 |

81 |

| Φ2.4×10 |

Circle flow |

Brim |

ZD80-4-LL |

6.44 |

570 |

32-36 |

118 |

| Φ2.6×10 |

Circle flow |

Brim |

JDX710 |

6.3 |

800 |

45-50 |

130 |

| Φ3×9 |

Open flow |

Brim |

JDX800 |

6.3 |

1000 |

55-60 |

158 |

| Φ3.2×9 |

Circle flow |

Brim |

MBY900 |

7.1 |

1250 |

62-65 |

195 |

| Φ3.5×10 |

Open flow |

Brim |

JDX900 |

5.84 |

1250 |

70-75 |

200 |

| Φ3.8×7.5 |

Circle flow |

Brim |

JDX900 |

5.6 |

1600 |

80 |

233 |

| Φ4.6×10+3.5 |

Circle flow |

Central shaft |

JQS3550 |

15.1 |

3550 |

190 |

415 |

| Φ4.6×10.5+3.5 |

Circle flow |

Central shaft |

JQS3550 |

15.1 |

3550 |

210 |

476 |