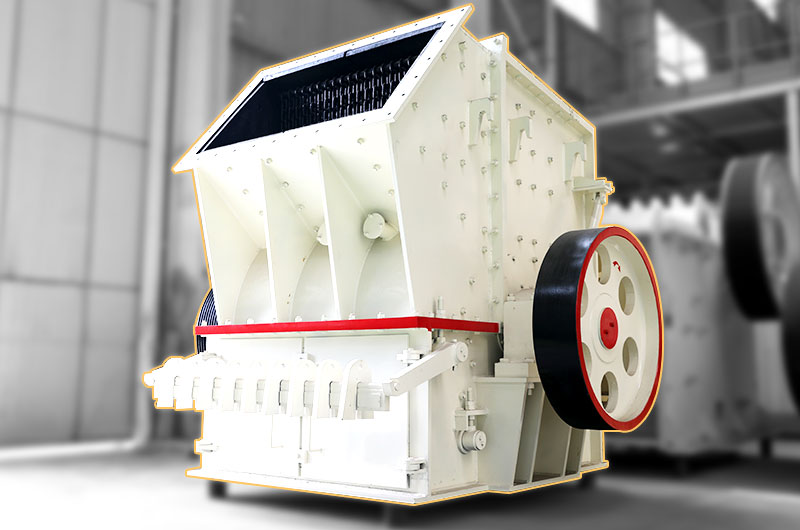

Introduction to the single-stage crusher

This series of single-stage crushers is a new crusher that is optimized under the introduction of advanced German technology. After years of improvement, it has developed into a more mature fourth generation product. The equipment can crush the large ore collected from the mine to an average particle size of 5mm, which is the replacement product of the traditional two-stage and three-stage crusher.

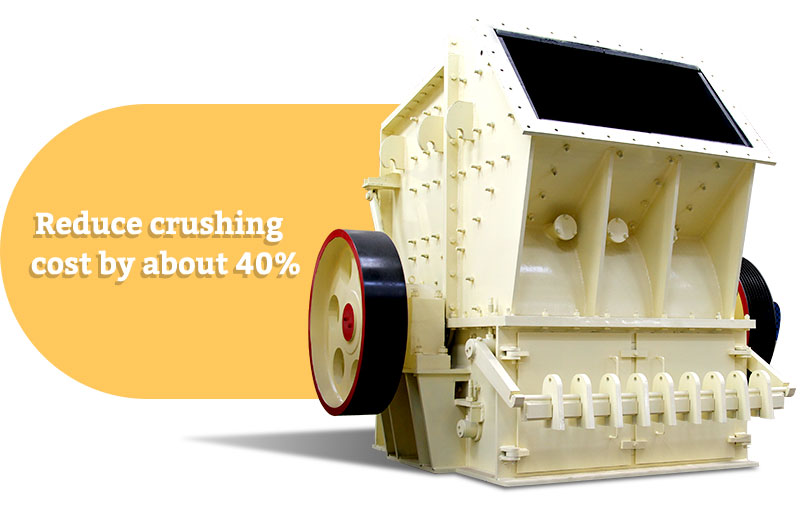

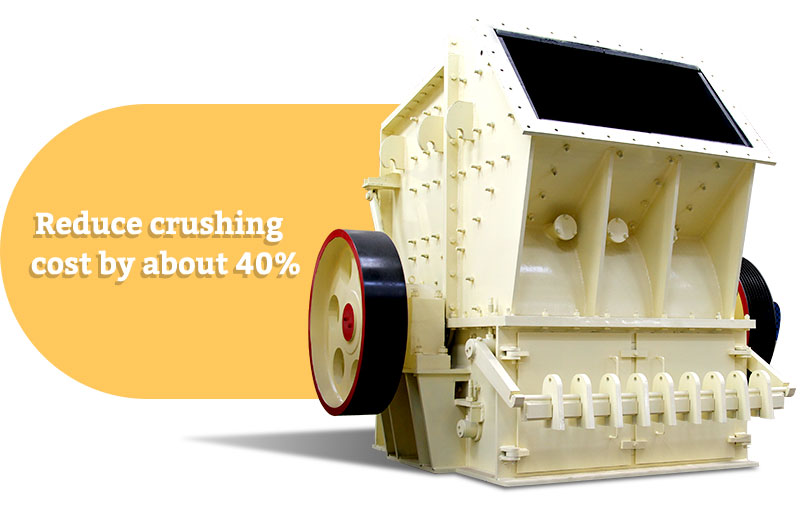

It simplifies the process, saves capital investment and production costs. Compared with the two-stage crusher, the single-stage crusher can save 45% of the one-time investment and reduce the crushing cost by about 40%. The operation is simple, the maintenance is convenient, and the labor intensity of the worker is reduced.

Single-stage crusher

Unique advantages:

The single-stage crusher can crush the materials into the grinding-need particle size. It has a large feeding size and large crushing ratio and has replaced the traditional two-stage crusher, simplified the working process and saved the production costs.

Fote single-stage crusher is the specialized crushing machine for cement production and is suitable to crush cement (argillaceous siltstone) and clay mixture. Also, single-stage crusher can be used to crush coal. Single-stage crusher is applied in cement production, large sand aggregate production and other engineering projects.

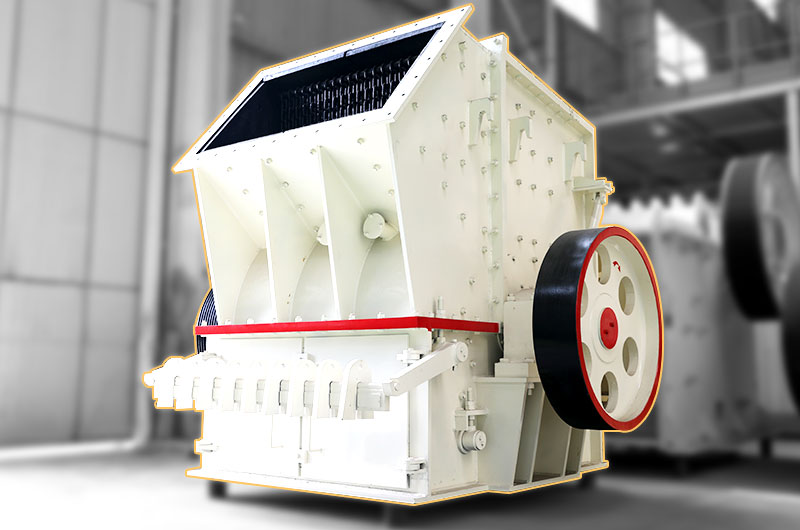

1.Single-stage replaced multi-stage to resist the limestone durable condition.

2.Hammer adopts the independent research and developed highly advanced composite material, prolonging life expectancy by 50%.

3.Hammer crusher adopts “stone strikes stone” patented technology to increase the self-crushing ratio and effectively decrease the bearing and load of the hammer and grid plate.

4.Latest and optimal grid plate design. Smooth discharge and fine particle size. And the long life expectancy of grid plate.

5.The feeding size can reach 1.3-1.5m. And the discharging size can be freely adjusted within the range of 3-150mm.

6.The shape of aggregate is good. The system supporting power is small, so the production cost is greatly reduced.

Characteristics of single-stage crusher

Working pricciple

The basic components are the chassis, rotor, hammerhead, intermediate bracket, and counterattack. When the single-stage crusher is working, the crushed materials are put into the broken cavity and fell into the middle bracket. The rotor drives the hammer in high speed under the function of an electric motor, and strike the material fell into the middle bracket. The shattered material hits the counter-attack plate, and is repeatedly impacted by the hammer in the crusher cavity, and finally crashed into the required particle size.

The paragram of single-stage crusher

Currently, there are generally three types of single-stage crusher in FTM company: DPC140、DPC160、DPC200. The model of DPC140, its feeding size should be controlled below 800mm, and its ideal output is as high as 100-140t/h. The model of DPC160, its feeding size should be controlled below 1000mm, and its ideal capacity is 150-240t/h. The model of DPC200, its feeding size is larger than the other two models. Its feeding size below the 1250mm will be ok. And its ideal capacity can reach 330-420t/h.

Therefore, the enterprise with small scale or the users that don’t have so much requirments on the capacity, the single-stage crusher of the above three models is sufficient for daily their needs. If youhave special production needs, FTM Machinery will customize for you. Here you will find what you need.

| Model |

Type |

Rotor diameter |

Feeding size

(mm) |

Product Size

(mm) |

Capacity

(t/h) |

Power

(kw) |

| DPC140 |

Single Rotor |

1400 |

≤800 |

<3-8 |

100-140 |

6P 160-220KW |

| DPC160 |

1600 |

≤1000 |

150-240 |

4P 280-355KW |

| DPC200 |

2000 |

≤1250 |

330-420 |

6P 500-630KW |

The service life of consumable parts of single-stage crusher

The service life of consumable parts of single-stage crusher is a problem that customers pay more attention to. The wearing parts generally refer to the hammer head. The hammer head plays an important role in the crushing process. The crusher without the hammer head is like a wolf without teeth. In general, our company’s single-stage crusher has significant performance advantages, long service life, and the price is very affordable. For more information on equipment prices, test machines, production sites, etc., you can directly consult for free or visit the customers’ sites.