Welcome to the photo gallery of our products, then you will find the lightspot of various equipment, and enjoy yourself !

Impact crusher is the machine of using the impact not the pressure to reduce the size of the raw material. FTM company introduced foreign advantaged technology to produce a kind of new impact crusher with no tension and cracks, special structure, little dust and cube finished products. It is equipped with the motor whose power is 6P 132KW and can meet the demands of many customers.

Impact crusher

1. Large crushing ratio and high productivity. The materials can be fully crushed in the deep cavity, which has enlarged the crushing ratio and improved productivity.

2. Wear-resistant and long service life. fragile parts are made of high strength wear resistant material. The gap between counterattack and hammer can be adjusted to reduce the wearing on the hammer. Besides, it is also equipped with safety devices to improve the life of the impact crusher overall.

3.Strong adaptability to materials. Various of rocks can be well shaped through the impact crusher. It can also provide a fine material for the grinding equipment. Therefore, the impact crusher is popular with the mining industry.

4. Well-shaped products. The impact crusher can shape for its raw material, which is the unique feature that the cone crusher doesn’t have. It can also be used as the sand maker for some plan with low requirement on the size of sand.

5.Flexible configuration and wide application. The impact crusher can be used on the fixed sandstone production line or a mobile crusher unit. It’s suitable for some factories that have a small scale or operates flexibly.

1.Quality of the equipment. The quality of machine itself is a key factor affecting the production capacity. Its quality directly affects the working capacity of the machine. A machine with good performance is stable in the process of operation and will not go wrong.

2.Performance of material. The performance of material also has a great influence on the capacity of products.

Impact crusher can break the stone below 350MPa, is suitable for crushing medium hardness stones, so impact crusher is is not recommended to crush the stones with higher hardness. Otherwise, the crusher will be damaged and the capacity of product will be reduced.

3.Operating procedures. In addition to external factors such as equipment and materials, human factors are also important.

Avoid the Abnormal phenomenon that bearing is hot or damaged, and impact crusher vibrates abnormally, workers should operate the machine according to the specification and inspect and maintain from time to time.

The rotor rotates at high speed under the driving of the motor. Then, the material collides with the plate hammer on the rotor, and is broken by high-speed impact from the plate hammer.

The broken material is rebounded to the liner and broken again. At last the broken material is discharged. Adjusting the gap between the counter frame and rotor can change the size and shape of the material.

Working principle of the impact crusher

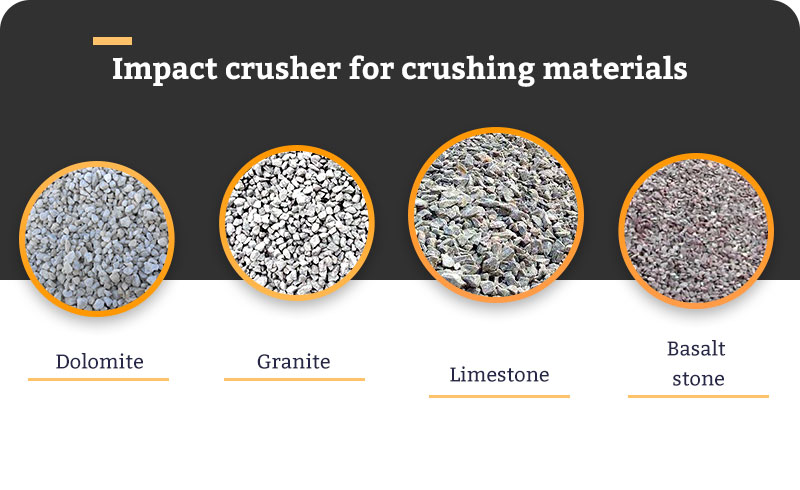

Because of wearable parts for the impact crusher, there is some limitation on the material with high hardness. It can process the coarse, medium and materials such as limestone, feldspar, calcite, talc, barite, rare earth, clay, kaolin, dolomite, kaolin, gypsum, graphite, etc.

Applied raw materials for the impact crusher

Capacity: 160t/h. Sand making line for the limestone(Highway stone production base), 160t/h

The project was built by a company in Indonesia for limestone processing, and the finished aggregate is used for local highways. This production line is the classic configuration of our company: jaw crusher, impact crusher, sand maker. Its high production capacity, large output, well-shaped products, providing high-quality stone for the construction of a highway.

Capacity: 300t/h. We use the jaw crusher and impact crusher to process the calcite. The customer is very for its productivity and had a plan to purchase another one to expand the production scale. Capacity: 300t/h

Production sites of customers

As we all know, impact crushers are often used in the secondary crushing process during which we can get more fine-sized materials.But as for jaw crushers, it is only used in the primary crushing equipment except for the PEX jaw crushers which are also used in secondary crushing. But both of them are so important crushing machines in mining and quarry industry.

From China Fote cases above, you may know that the jaw crushers are used for primary crushing and the impact crushers are used for secondary crushing, what means the match like that are the most important and popular solutions for your projects. All of our customers make a successful business and so satisfied with our impactor machines because of best services including pre-sale, shipping and after sale. FTM Machinery as a the largest mining machine manufacturer can ensure every impact crusher for sale are high quality with reasonable prices. If you are kind of interested and want to more about these impact rock crushers, we’ll warmly welcome you to visit our company or leaving a message.

Contact

E-mail:vip@sinoftm.com

Address: No.168 Wutong Street, High-Tech Industrial Development Zone of Zhengzhou City, China.

Hot Products

Future Prospect

We would like to cooperate with customers all around the world, and welcome you sincerely !

Inquiry Online 7×24 Online