Welcome to the photo gallery of our products, then you will find the lightspot of various equipment, and enjoy yourself !

Jaw crusher is used in the first process of crushing various mineral rocks with compressive strength no higher than 320MPa, such as the river pebble, calcite, granite, aggregates, quartz, concrete, dolomite, bluestone, gold ore, iron ore, coal gangue, glass, limestone, construction waste, etc.

Raw materials that the jaw crusher can process

When the jaw crusher is working, the movable jaws periodically reciprocate the jaws, moving up and down. When approaching, the material is crushed by crushing, splitting, and impact between the two jaws. When leaving, the broken material is discharged from the discharge port by gravity.

Working principle of the jaw crusher

1.Easy operation and low failure rate. The jaw crusher is designed in a modular manner and can remotely monitor and adjust the settings of feeders, crushers, and conveyors. It was equipped with a lubrication system, so it’s easy to work and maintenance.

2.High production capacity. We use oversized bearings and forged spindles, design a low suspension motion mechanism to achieve the larger crushing ratio. It has a deep cavity to crush efficiently.

3.Excellent casting engineering. Jaw crusher is made up with rack, seesaw, side guard, eccentric shaft and transmission. The eccentric shaft, made of high carbon steel, is the core part of the jaw crusher and has a large bending torque.

4.Environmental protection. Adopt advanced shock absorption and sound insulation technology to reduce noise pollution generated when the equipment is running, making the working environment more friendly and in line with environmental protection requirements.

5.Longer service life. Because of Using high wear-resistant tooth plate, it can perfectly realize longer service life and cost-saving.

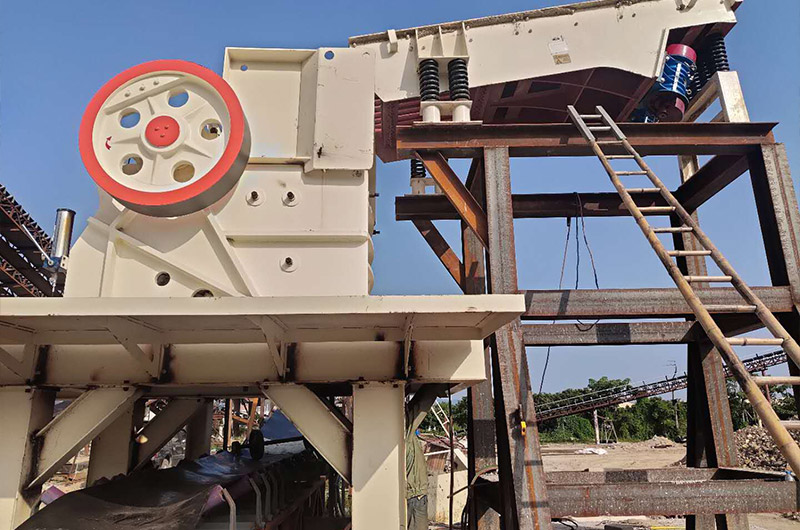

Jaw rock crusher plant case1: Its main material is the aggregates, and the finished products of the jaw crusher machines are used for local hydropower infrastructure construction. The three-stage project includes the jaw crusher, cone crusher and sand maker to process the pebble, among which the jaw crusher is used for the primary machine. The aggregates can be crushed into the medium granularity one time.

Aggregates crushing site 1000 t/h

Jaw rock crusher plant case2: The granite is very hard, so the requirement on the wear resistance of the machine is very high. We recommend the big jaw crusher HD125 950*1250 firstly, which can reduce the cost. Then, the cone crusher crushes further and the sand maker will shape the granite particularly and evenly. This guarantees the quality of the finished product.

Granite crushing site 150 t/h

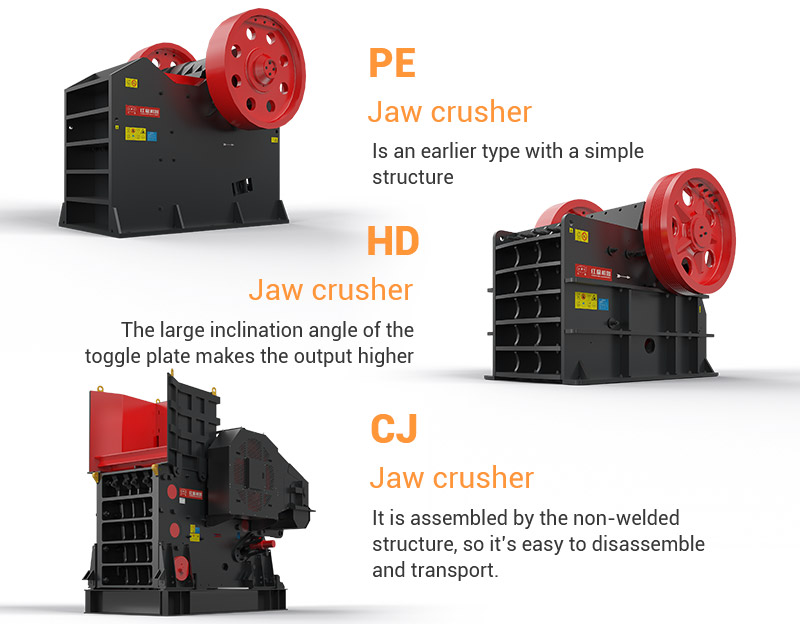

Jaw crusher has been updated for three times. There are different types and series of jaw crusher. The primary serie was researched and developed as the PE jaw crusher. In order to improve the quality of the jaw crusher, Henan Fote Heavy Mining Machinery which is a jaw crusher manufacturer in China actively introduced advanced technology from German to produce another serie of jaw crusher (HD) with a larger crushing ratio and higher output capacity. After researching from the market and the feedback from users, FTM machinery developed the European version jaw crusher(CJ).

Comparing with the HD jaw crusher, the CJ has more advantages. It is assembled by the non-welded structure, so it’s easy to disassemble and transport. Besides, a motor is installed at the end of the machine. Therefore, the CJ jaw crusher has been popular among the majority of users. Besides, we also have many types of mobile crushers and crushers plants.

PE jaw crusher VS HD jaw crusher VS CJ jaw crusher

To extend the life of crushers and reduce your losses, as one of jaw crusher dealers in china, we can also provide you with the high-quality jaw crusher parts like frame part, seesaw, bracket, crusher, lubrication system, etc. Although we are one of Chinese jaw crusher manufacturers, we sale our products all over the world and the price of jaw crusher is affordable to our customers. Thanks to the great initiative of Chinese Government One Belt and One Road, we’ve gotten a lot of partners from India, Zambia, Ethiopia, Pakistan, etc.

High-quality jaw crusher parts

To price of the jaw crusher, it depends on your model choice or your project plans. That means, the model choice is dependent on your project information like raw material, feeding size, discharging size and capacity demand. In general, if you just want to crush rocks at your home and backyard, small or mini jaw crushers would be the best choice for you because they can perfectly work at the limited spaces and cost a little. Otherwise, the big jaw stone crushers would be great, which means how much does the jaw rock crusher cost depends on customers’ various needs. At FTM company which always devotes itself to manufacture the best Chinese jaw crushers, we have small and mini jaw crushers as well as big one for sale. If you want to know the price, pictures or specification PDF of jaw rock crusher, please leave a message to us.

| Model | Max.Feeding size (mm) | Capacity (t/h) |

| PE 250×400 | 210 | 5-21 |

| PE 400×600 | 340 | 16-64 |

| PE 500×750 | 425 | 40-110 |

| PE 600×750 | 500 | 80-240 |

| PE 600×900 | 500 | 50-160 |

| PE 750×1060 | 630 | 110-320 |

| PE 900×1200 | 750 | 220-380 |

| PE 1200×1500 | 1020 | 400-1000 |

| PE 1500×1800 | 1200 | 500-1200 |

| PEX 250×1200 | 210 | 20-61 |

| PEX 300×1300 | 250 | 16-105 |

| Model | Feed opening size(mm) | Max.Feeding size (mm) | Adjustment range of discharge port (mm) | Capacity(t/h) | Rotation speed of eccentric shaft(r/min) | Power (kw) | Dimensions(L×W×H) (mm) |

| PE 150×250 | 150×250 | 125 | 10-40 | 1-3 | 268 | 4P 5.5 | 760×700×860 |

| PE 200×300 | 200×300 | 180 | 15-50 | 2-6 | 260 | 4P 7.5 | 915×780×990 |

| PE 200×350 | 200×350 | 180 | 18-60 | 3-10 | 276 | 4P 11 | 1000×914×1112 |

| PE 250×400 | 250×400 | 210 | 20-70 | 5-21 | 300 | 6P 15 | 1100×1032×1285 |

| PE 400×600 | 400×600 | 340 | 40-100 | 16-64 | 270 | 6P 30 | 1623×1736×1615 |

| PE 500×750 | 500×750 | 425 | 50-100 | 40-110 | 268 | 6P 55 | 1920×1850×1920 |

| PE 600×750 | 600×750 | 500 | 150-200 | 80-240 | 268 | 6P 55 | 2020×1850×1920 |

| PE 600×900 | 600×900 | 500 | 65-160 | 50-160 | 254 | 6P 55 | 2530×1900×2340 |

| PE 750×1060 | 750×1060 | 630 | 80-180 | 110-320 | 245 | 8P 110 | 2680×2380×2785 |

| PE 900×1200 | 900×1200 | 750 | 100-200 | 220-380 | 208 | 8P 110 | 3470×2876×3330 |

| PE1200×1500 | 1200×1500 | 1020 | 150-350 | 400-1000 | 180 | 8P 160-245 | 4850×3220×3680 |

| PE1500×1800 | 1500×1800 | 1200 | 220-350 | 500-1200 | 180 | 8P 280-380 | 5160×3660×4248 |

| PEX 150×750 | 150×750 | 120 | 18-48 | 8-25 | 320 | 4P 15 | 1170×1575×1030 |

| PEX 250×750 | 250×750 | 210 | 25-60 | 13-35 | 320 | 6P 22 | 1550×1730×1470 |

| PEX 250×1000 | 250×1000 | 210 | 25-60 | 16-52 | 330 | 6P 30 | 1580×2006×1390 |

| PEX 250×1200 | 250×1200 | 210 | 25-60 | 20-61 | 330 | 6P 37 | 1780×2214×1430 |

| PEX 300×1300 | 300×1300 | 250 | 20-90 | 16-105 | 300 | 6P 55 | 2210×2320×1723 |

Note:processing Capacity May Vary With Different Materials And Feeding Sizes.

| Model | Max.Feeding size (mm) | Capacity (t/h) |

| PE 150×250 | 125 | 1-3 |

| PE 200×300 | 180 | 2-6 |

| PE 200×350 | 180 | 3-10 |

| PE 250×400 | 210 | 5-21 |

| PE 400×600 | 340 | 16-64 |

| PE 500×750 | 425 | 40-110 |

| PE 600×750 | 500 | 80-240 |

| PE 600×900 | 500 | 50-160 |

| PE 750×1060 | 630 | 110-320 |

| PE 900×1200 | 750 | 220-380 |

| PE 1200×1500 | 1020 | 400-1000 |

| PE 1500×1800 | 1200 | 500-1200 |

| PEX 150×750 | 120 | 8-25 |

| PEX 250×750 | 210 | 13-35 |

| PEX 250×1000 | 210 | 16-52 |

| PEX 250×1200 | 210 | 20-61 |

| PEX 300×1300 | 250 | 16-105 |

Note:processing Capacity May Vary With Different Materials And Feeding Sizes.

Related:

Contact

E-mail:vip@sinoftm.com

Address: No.168 Wutong Street, High-Tech Industrial Development Zone of Zhengzhou City, China.

Hot Products

Future Prospect

We would like to cooperate with customers all around the world, and welcome you sincerely !

Inquiry Online 7×24 Online