Welcome to the photo gallery of our products, then you will find the lightspot of various equipment, and enjoy yourself !

Hammer crusher is a kind of mining crusher for crushing limestone, coal, dolomite, brick, tile, gangue and other materials and sometimes it is also called coal hammer crusher. It is a kind of equipment which could directly crush the materials with the largest particle size like 600-1800mm into less than 25mm. Hammer crusher is widely used in cement, chemical, electricity, metallurgy and other industries.

Heavy hammer crusher is used for crushing all kinds of hard and weak abrasive materials. The compressive strength of the material should not exceed 100MPa and the moisture content should be less than 15%.

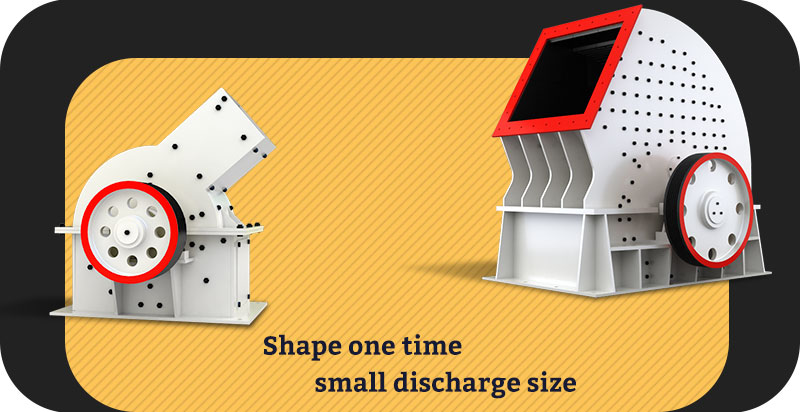

Hammer crusher and heavy hammer crusher both can shape materials on time

The large stone hammer crusher of our company is developed on the basis of the traditional hammer crusher. Any parts of our hammer rock crusher like hammers and hammer mill screens are high-quality and easy to maintain in which its unique advantages are not possessed by other equipment.

High quality. All parts of our hammer mill crushers are made of high-quality materials, which greatly reduce the downtime and prolong the service life.

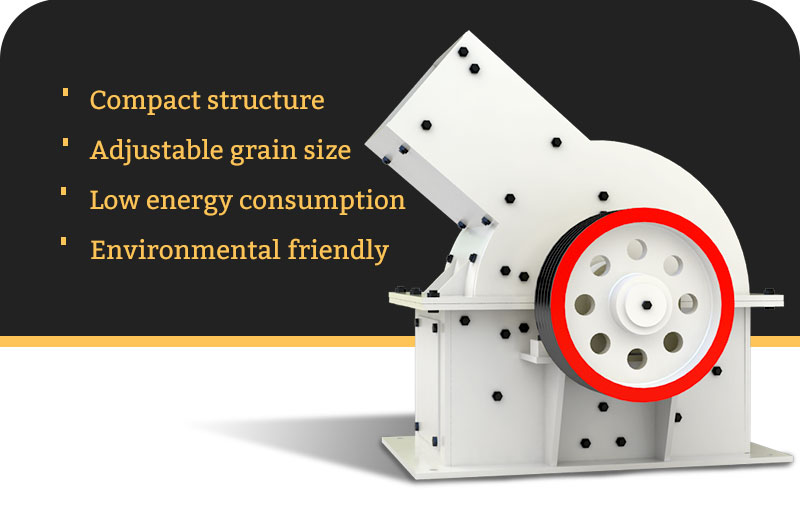

Compact structure. Because this equipment is processed by a new process, the hammer crusher’s internal structure design is reasonable. The small size of the equipment results in reduced area.

Granularity is adjustable. The particle size of finished products can be adjusted according to the requirements of users.

Low energy consumption. Compared with the same type of equipment on the market, the energy consumption of this device can be reduced by more than 50%, saving 100,000 operating costs for the processing plant every year.

Environmental protection. Nowadys, a lot of hammer mill manufacturers pay more attention to the environmental protection. Advanced dust removal device allows the equipment to work without any dust. Emission standards are also in the prescribed range, which really plays a role in protecting the environment.

Low noise. When the hammering machines are running, they would produce little noise. And even the hammer crusher works at night, it will not have any impact on the lives of people around so that most of minerals do love purchase the rock crushing machines for sale.

Excellent sealing. The structure of the hammer crusher is well sealed, thus can solve both the problems of the dust pollution of the crushing workshop and the air leakage of the hammer crushing machine body.

Characteristics of reversible hammer crusher

The main working part of heavy hammer crusher is the rotor with a hammer (also known as hammerhead). The rotor consists of a spindle, disk, pin, and hammer. The motor drives the rotor to rotate at high speed in the crushing cavity. Materials go into the hammer crusher and crushed by the high-speed rotating hammer. Driven by the hammer, the crushed materials are then thrown to the crushing plate. And the large size materials are crushed by the hammer in the grate bars and small size ones are discharged from the grate bars.

Hammer crusher working principle

In a world, FTM Machinery has the advantaged technology to produce the hammer crusher with competitive price. For the customer, all hammer mills such as big hammer crushers, small hammer mills can guarantee and save production cost. But the different machines above are usually applied in various kinds of scale and the best hammer crusher depends on customers’ needs on production, materials like coal, limestone, etc. If you are interested in our hammer crusher machine, please feel free leave your message on our website.

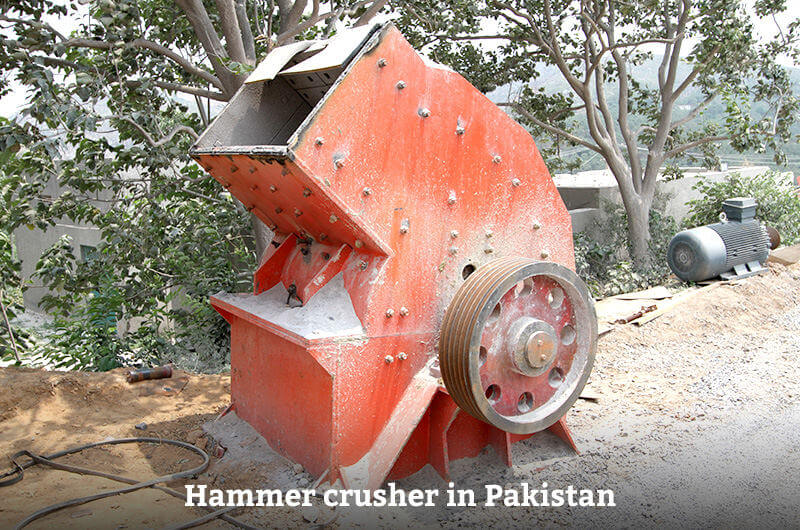

Hammer crusher in Pakistan

FTM Machinery, as a famous mining crushers’ manufacturer can also offer you hammer crusher spare parts and hammer mills for gold mining. Its hammer is the quick-wear part. Please check the parts regularly to improve productivity and ensure safety. If you have any other questions, you can leave a message or send us an e-mail. We’ll always at your service.

| Specification | Capacity(t/h) | Power (kw) |

| PC 400×300 | 3-10 | 4P 11 |

| PC 600×400 | 6-22 | 4P 22 |

| PC 800×600 | 10-40 | 4P 55 |

| PC 1000×800 | 15-50 | 4P 75 |

| PC 1000×1000 | 18-75 | 4P 90 |

| PC 1200×1200 | 22-95 | 4P 132 |

| Specification | Capacity(t/h) | Power (kw) |

| PC 400×300 | 3-10 | 4P 11 |

| PC 600×400 | 6-22 | 4P 22 |

| PC 800×600 | 10-40 | 4P 55 |

| PC 1000×800 | 15-50 | 4P 75 |

| PC 1000×1000 | 18-75 | 4P 90 |

| PC 1200×1200 | 22-95 | 4P 132 |

Note:processing Capacity May Vary With Different Materials And Feeding Sizes.

| Specification | Capacity(t/h) | Power (kw) |

| PC 400×300 | 3-10 | 4P 11 |

| PC 600×400 | 6-22 | 4P 22 |

| PC 800×600 | 10-40 | 4P 55 |

| PC 1000×800 | 15-50 | 4P 75 |

| PC 1000×1000 | 18-75 | 4P 90 |

| PC 1200×1200 | 22-95 | 4P 132 |

Note:processing Capacity May Vary With Different Materials And Feeding Sizes.

Contact

E-mail:vip@sinoftm.com

Address: No.168 Wutong Street, High-Tech Industrial Development Zone of Zhengzhou City, China.

Hot Products

Future Prospect

We would like to cooperate with customers all around the world, and welcome you sincerely !

Inquiry Online 7×24 Online