Welcome to the photo gallery of our products, then you will find the lightspot of various equipment, and enjoy yourself !

Raymond mill is mainly used for barite, calcite, potassium feldspar, talc, marble, limestone, dolomite, fluorite, lime, activated clay, activated carbon, bentonite, cement, phosphate rock, gypsum, etc.

The Moh’s hardness of any raw material is no more than 9.3, and the humidity is less than 6%. The size of finished materials can be adjusted in the range of 80-325 mesh and some even can reach 600 meash.The processing capacity reaches up to 60 TPH.

Raymond grinding mill machine is widely used in the grinding of mineral products in metallurgy, building materials, chemical industry, mining and other fields. It is suitable for processing various non-flammable and explosive materials .

The production of raymond mill in Pakistian

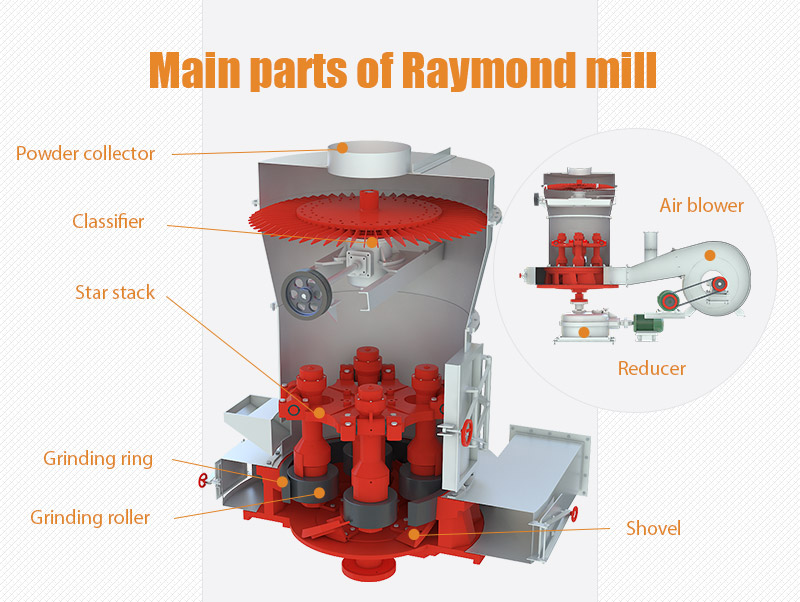

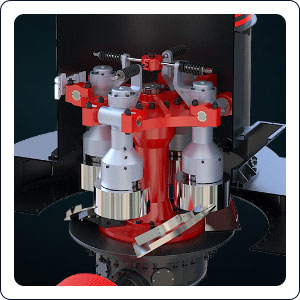

Raymond mill consists of main engine, analyzer, fan, finished cyclone, fine powder cyclone and duct. And the main engine is made up with rack, inlet volute, blade, grinding roller, grinding ring, casing. Generally, users will also choose a jaw crusher, bucket elevator, electromagnetic vibrating feeder, etc. as auxiliary equipment according to their own needs.

The structure of Raymond mill

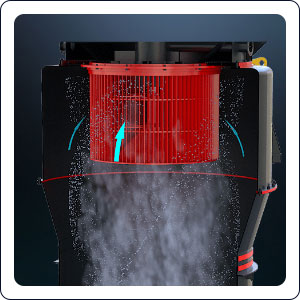

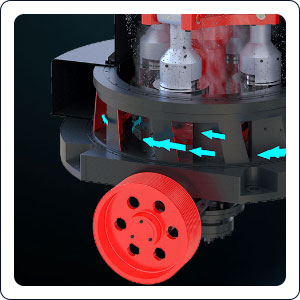

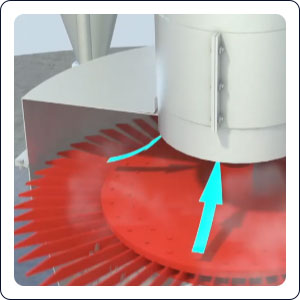

The Raymond mill crushes materials through the mutual compression between its roller and grinding ring. In operation, the transmission mechanism rotates the roller shaft rapidly. The grinding roller operates against a stationary grinding ring. As material enters the mill via a feeder, a blade positioned at the roller’s front edge continually feeds the material into the grinding area between the roller and ring. As the grinding roller revolves around its axis, it steadily moves outward, getting closer to and eventually pressing against the grinding ring. Concurrently, the material caught between the roller and ring is crushed under the applied pressure, effectively accomplishing the full grinding process.

Clearly visiable grinding process

1.High Screening Rate: Raymond mill boasts a superior screening rate of up to 99%, outperforming other grinding machines.

2.Durable Drive System: Sealed gearbox and pulley ensure stable, reliable rotation and extended lifespan due to high-quality steel components.

3.Environmentally Friendly Operation: Negative pressure circulation system with air purified through a small cyclone collector for eco-compliance.

4.Automated Control: PLC electrical automation enhances ease of use, minimizes maintenance costs, and creates a quiet, low-pollution production environment.

5.Adjustable Fineness & Versatility: Grinding fineness ranges from 80-600 mesh, making Fote Raymond mill highly adaptable for various non-metallic ores.

6.Extended Wear Part Life: Modularly designed wearing parts facilitate quick replacement and maintenance, indirectly extending service life.

Raw material: limestone

Finished product size: 325 mesh

Capacity: 15-20T/H

Feedback from customer: “We have strict environmental protection requirements here. Before we purchased the Raymond mill, we made a detailed inspection and selected FTM Machinery’s new grinding mill. FTM Machinery, as the Raymond mill manufacturer, has great strength, its factory processing ability is strong, and after-sales service is also in place. Its price is cheap. I think this type of grinding mill is very suitable for our project. The equipment is very efficient and environmentally friendly, bringing us a revolutionary experience and much benefit.”

Environmental-friendly desulfurization limestone powder grinding mill

Raw material: calcium carbonate

Finished product size: 315 mesh

Feedback from customer: “Calcium carbonate has always provided good quality raw materials for the building materials, chemicals, coatings, paints and other industries. We choose 40 Raymond mills from FTM Machinery to produce the powder with 315 mesh.”

Calcium carnonate grinding production site

The Raymond mill price is one of the main concerns for the customers, and the demand of different grinding manufacturers are different according to the price of the grinding mill equipment. The device of the FTM Machinery mill machine is not only in quality but also at a very affordable price with respect to the same type of mill on the market.

FTM Machinery is a famous Raymond mill manufacturer in China. There are limestone grinding mill, gypsum grinding mill, calcium carbonate grinding mill, and clinker grinding in Fote. The products all have great quality, perfect service and reasonable price. You can send an e-mail or leave a message to know more about the machine.

| Model | Output Size (mm) |

Shift output of different materia fineness(t) |

| 4525 | 0.173-0.044 | 16-176 |

| 4119 | 0.173-0.044 | 8-78 |

| Model | 4525 | 4119 |

| Feeding Size(mm) | ≤30 | ≤25 |

| Output Size(mm) | 0.173-0.044 | 0.173-0.044 |

| Shift Output of Different Material Fineness(t) | 16-176 | 8-78 |

| Rotation Speed of Central Shaft(r/min) | 82 | 105 |

| Ring Diameter(mm) | 1770 | 1400 |

| Roller Diameter(mm) | 450 | 410 |

| Roller Height(mm) | 250 | 190 |

| Main Motor(kw) | Y315M-4-132 | Y280S-4-75 |

| Fan Motor | Y315M-4-132 | Y280S-4-75 |

| Analyzer Motor | YCT250-4A-18.5 | YCT200-4B-7.5 |

| Model | Output Size (mm) |

Shift output of different materia fineness(t) |

| 4525 | 0.173-0.044 | 16-176 |

| 4119 | 0.173-0.044 | 8-78 |

Related:

Contact

E-mail:vip@sinoftm.com

Address: No.168 Wutong Street, High-Tech Industrial Development Zone of Zhengzhou City, China.

Hot Products

Future Prospect

We would like to cooperate with customers all around the world, and welcome you sincerely !

Inquiry Online 7×24 Online