Welcome to the photo gallery of our products, then you will find the lightspot of various equipment, and enjoy yourself !

After the lime powder is pressed and formed by the high-pressure quick lime briquetting machine, it can replace the lumpy quick lime and serve as a good desulfurizer during the process of converter steelmaking. At the same time, in the production of calcium carbide, quicklime briquettes can also be used instead of lumpy quick lime to smelt calcium carbide.

Application of lime briquette machine

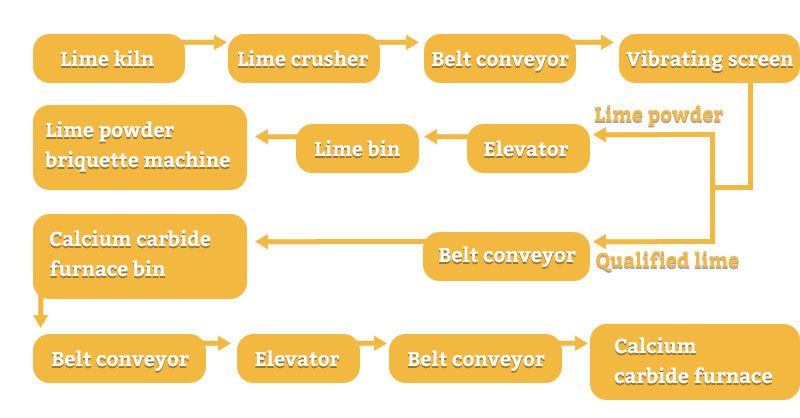

The calcium carbide production process has special requirements on the particle size of the raw material for the furnace. The lime must be screened before the furnace to separate lime powder below 5 inln, in order to ensure the safety, stability, high quality, and high yield of calcium carbide furnace.

Statistics show that the quick lime powder that hasn’t been sieved out, whose amount accounts for 10% ~ 15% of the lime in the furnace, is generally disposed of as the three wastes by calcium carbide manufacturers.

However, the utilization rate of lime powders producing calcium carbide reaches more than 95% by directly sending them into a calcium carbide furnace after being pelletized by a high-pressure briquetting machine, which significantly reduces the cost of lime production.

Process of Making Lime Powder into briquettes for calcium carbide furnace use

The lime powder is normally distributed. Powders below 2 mm account for 90.08% of the total, among which below 0.5 mm 35.64%. Powders above 5 mm account for only 1.18%. From the particle size distribution of the lime powder, it meets the requirements of the high-pressure briquette machine on the particle size of the material.

Besides, The lime powder can be pressed into balls production of magnesium by Pidgeonprocess. In the past, most of the lime powder in China’s metallurgical industry was abandoned, resulting in a great waste of resources. With the increasing energy of resources, the utilization of lime powder is more and more important in the metallurgical industry.

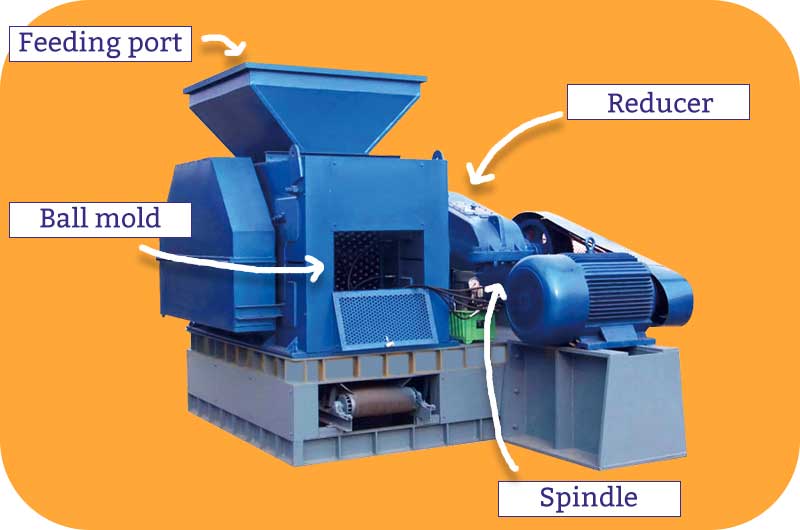

The quick lime briquette machine or the lime dry powder briquette machine belongs to the twin roller briquette machines and it owns a pair of cylindrical squeeze rollers paralleling with the axis. There are half ball socket structures with the same size and shape on top of the squeeze rollers. When materials fall into the space between the rollers from the top end, the rollers will revolve inwards at the same time to compress the materials into balls.

FTM briquette machine for sale

There are three main parts of lime powder briquetting machine.

1.Feeding part: this part can guarantee materials enter the double rollers evenly. The feeding part generally uses the spiral feeder to compress the materials into the main feeding port, which can keep the uniformity of the feeding materials and help to produce regular balls.

2.Driving part: the main driving system is made up of electric motor, triangle belt, reducer, open gear, and rollers. The main engine is powered by the electromagnetic speed control motor and drives the squeeze roller via the belt pulley and gear reducer, which makes sure the two squeeze rollers run at the same time. A hydraulic device is installed behind the squeeze roller in order to guarantee the required briquetting pressure.

3.Forming part: it is the core part main the machine with squeeze rollers. The squeeze rollers are equipped with pressure protective device, so when hard materials enter, the rollers will back automatically in order to prevent the rollers from being damaged.

Main parts of the lime briquette machine

Briquette machine is suitable for the suppression of a variety of materials, which can improve the utilization rate of raw materials, save resources, economic and environmental protection, and is easy to transport the finished balls. Firstly, the machine should process the lime block into powder, then process the powder into balls. There are mainly four steps for the processing of lime with briquettes machine:

First, crushing the raw lime. Using crushers to break the raw lime that is transported from mining plants into powder or particles.

Second, mixing and stirring materials. Crushed lime powder is put into the feeder. In the manufacturing process, adhesives other dry powders are added. In a mixing mixer, the original lime powder can enter the briquette machine after a sufficient mixing.

Third, pressing balls. Press can also be used to suppress coal mine by-products such as coal powder, cinders, and sludge. Suppressing these resources into spherical or block shapes is a benefit to processing or transportation.

Fourth. Drying. There is a drying process after the lime powder is pressed into the molding. You can dry the materials with a machine or natural sunshine. If there is something needed, you can purchase a dryer to help dry.FTM company also can offer you the dryer.

Quicklime briquetting plant for sale in Iran

Simply describing the technique of quicklime powder briquette machine, Screen the lime from the kiln and send the powders <3mm into the high-pressure quick lime briquetting machine to pelletize them into the size of 35mm * 25mm * 15mm (length * width * thickness).

It can also be customized according to the requirements of the buyer. It is 1.9-2.2g/cm3 with the drop strength equivalent to that of lumpy lime. After screening, send qualified quicklime balls into the finished product bin for smelting.

Production of magnesium by Pidgeonprocess is a method of hot reduction magnesium smelting by reducing the calcined dolomite to magnesium metal by using a ferrosilicon reducing agent in a reduction tank. It includes dolomite calcination, grinding and ball pressing, vacuum heat reduction, and other processes.

The process of calcining dolomite should be as fast as possible (generally no more than 4h), and the pellets should be placed in a sealed paper bag to prevent the activity of the material due to the moisture absorption.

To the other applications of Quick Lime Briquetting Machine, it can also make briquettes of aluminum scraps, activated carbon, alumina, bauxite, caustic soda, charcoal, clay, coke breeze, coal, cryolite, chemical fertilizers, plastics, limestone, pigments, urea, etc.

Quick lime briquetting machine wide application ranges

To the detailed price and design PDF, as well as FTM manufacturer qualification of Quicklime briquette machine, You can leave your demands on our website, then our sales man will soon contact with you for sharing details. Briquetting machine has exported to UK, kenya, nigeria, USA, philipines, south africa, australia, canada, Ireland, etc. Welcome you to zhengzhou, henan, china for a site visit!

| Model | Roller Diameter (mm) |

Capacity (t/h) |

| FTMQ290 | 290 | 1-2.5 |

| FTMQ360 | 360 | 3-5 |

| Heavy FTMQ360 | 360 | 3-5 |

| FTMQ430 | 430 | 5-8 |

| Heavy FTMQ430 | 430 | 5-8 |

| FTMQ500 | 500 | 8-11 |

| FTMQ650 | 650 | 10-15 |

| FTMQ750 | 750 | 20-25 |

| FTMQ850 | 850 | 20-28 |

| FTMQ1000 | 1000 | 25-35 |

| Model | Roller Diameter (mm) |

Capacity(t/h) | Power(kw) | Reducer |

| FTMQ290 | 290 | 1-2.5 | 5.5-7.5 | 350 |

| FTMQ360 | 360 | 3-5 | 7.5-11 | 350 |

| Heavy FTMQ360 | 360 | 3-5 | 7.5-11 | 400 |

| FTMQ430 | 430 | 5-8 | 15 | 400 |

| Heavy FTMQ430 | 430 | 5-8 | 15 | 500 |

| FTMQ500 | 500 | 8-11 | 30 | 650 |

| FTMQ650 | 650 | 10-15 | 37-45 | 750 |

| FTMQ750 | 750 | 20-25 | 45 | 750 |

| FTMQ850 | 850 | 20-28 | 55 | 850 |

| FTMQ1000 | 1000 | 25-35 | 90 | 1000 |

| Model | Roller Diameter (mm) |

Capacity (t/h) |

| FTMQ290 | 290 | 1-2.5 |

| FTMQ360 | 360 | 3-5 |

| Heavy FTMQ360 | 360 | 3-5 |

| FTMQ430 | 430 | 5-8 |

| Heavy FTMQ430 | 430 | 5-8 |

| FTMQ500 | 500 | 8-11 |

| FTMQ650 | 650 | 10-15 |

| FTMQ750 | 750 | 20-25 |

| FTMQ850 | 850 | 20-28 |

| FTMQ1000 | 1000 | 25-35 |

Contact

E-mail:vip@sinoftm.com

Address: No.168 Wutong Street, High-Tech Industrial Development Zone of Zhengzhou City, China.

Hot Products

Future Prospect

We would like to cooperate with customers all around the world, and welcome you sincerely !

Inquiry Online 7×24 Online