Common equipment: jaw crusher, ball mill, flotation cell

Applied material: gold ore, copper ore, limestone, quartz, chrome, cement, etc.

Production Capacity: 1-150t/h

Common equipment: jaw crusher, ball mill, flotation cell

Applied material: gold ore, copper ore, limestone, quartz, chrome, cement, etc.

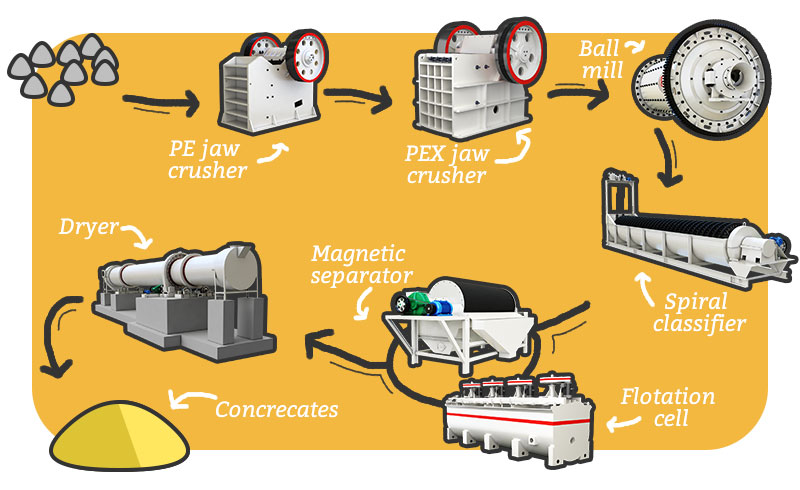

An ore beneficiation plant upgrades raw ore into concentrate by separating valuable minerals from waste rock. The core process involves crushing the ore, then using methods like flotation, magnetic or gravity separation based on mineral properties. Finally, the concentrate is dewatered.

It processes various materials, including iron ore, copper, gold, lead, zinc, nickel, coal, phosphates, etc.

The gravity method is to separate minerals based on the difference in relative density of minerals. Mineral particles with different densities influenced by fluid power and various mechanical forces, which will result in suitable loose delamination and separation conditions to separate the different density of the ore particles.

The flotation method is to use the flotation agent to process minerals attached to the bubble according to different physical and chemical properties of mineral surfaces.

Non-ferrous metal ores such as copper, lead, zinc, sulfur, and molybdenum can use the flotation method to process. Some ferrous metals, rare metals and some non-metallic ores, such as graphite ore, apatite, etc.are also selected by flotation.

The magnetic separation method is based on the difference of mineral magnetism, and different minerals are subjected to different forces in the magnetic field of the magnetic separator. Non-ferrous and rare metal ores such as iron, manganese, and chromium can use the magnetic separation method to separate from the minerals.

For the three methods, they have the same necessary machines in the beneficiation process, such as feeder, PE jaw crusher, PEX jaw crusher, ball mill, spiral classifier, and all these machines can be supplied from FTM Machinery. Generally, water is usually used to clean minerals during the beneficiation process.

In addition to the necessary equipment, different beneficiation methods also have a certain machine. The gravity beneficiation line also use the jigger, spiral chute, shaking table; flotation beneficiation line uses the stirring tank, flotation cell, foam tank, and dryer; magnetic beneficiation line uses the magnetic separator or dryer. Generally, water is usually used to clean minerals during the beneficiation process, but there is a kind of iron ore mining that does not require water. Correspondingly, its purity is low.

The magnetic separation line consists of feeder, jaw crusher, screen, ball mill, classifier, magnetic separator, concentrator, and dryer. They combine with hoist and conveyor to make up the complete beneficiation production line.

This beneficiation production line has the advantages of high efficiency, energy-saving, large capacity, and economy. Customers usually process the ore in the beneficiation plant. The following three basic processes are generally included.

1.Preparation. Before the beneficiation, we should crush, screen, grind, and classify the raw ore. The purpose of this process is to separate the useful minerals from the gangue mineral monomers and to dissociate the various useful minerals from each other.

Besides, this process creates suitable conditions for the next separation process. However, some beneficiation plants don’t wash or select waste ores because of ore properties and the need for sorting.

2.Separation. Fote company uses the methods of gravity, separation, and flotation to separate useful minerals from crushed gangue minerals and let the useful minerals be separated from each other. Finally, you can get the concentrates, tailings, and sometimes mines.

In the process of beneficiation, the first step is called rougher. The crude product obtained by rough selection is further selected to obtain final products with high quality. The next step is called the cleaner. And the last step is a scavenger. The crude product after roughly selecting is further selected, and the middle ore is returned to the first step or processed separately to get high recovery products.

Generally, after the processing of beneficiation, the purity of iron ore is about 60%, the copper ore is about 25%, and the cobalt ore is about 20%.

3.Finishing work. After the separation, you should dry the concentrates and tailings. The fine materials should be precipitated, concentrated, filtrated, dried and washed.

Main equipment of beneficiation plant

1.Compact structure. Fote company offers the necessary equipment of the beneficiation process to customers. The advantages of close cooperation between the equipment, high-speed material circulation can help customers save plenty of time.

2.A high degree of automation. The mineral processing is highly automated, controlled by a computer, and equipped with a security alarm system.

3.Low failure rate. Each equipment is made of wear-resistant materials, and the low failure rate can greatly reduce the production and maintenance costs of the whole production line.

4.Energy-saving and environmental. The beneficiation production line is equipped with perfect dust removal equipment. The reasonable layout is beneficial to convey the raw materials. And the sprinkler system can reduce dust during the production. Moreover, noise pollution is small.

Tantalite beneficiation plant vedio

If you have any project about the mining, FTM Machinery can provide you the equipment you want. Besides, we have the complete after-sales service system, so you don’t be worry about the installment or technical support problems. Welcome to FTM company for a visit or you can consult online for more details. Zhengzhou Fote company allow you to carry your material for a test on the machine before ordering. In addition, you can also come to pour company for a visit.

Contact

E-mail:vip@sinoftm.com

Address: Tanxiang Road, High-Tech Industrial Development Zone of Zhengzhou City, P. R. China.

Hot Products

Leave your personal information(Only kept by FTM), for sending a favorable price meets your production budget.

Inquiry Online 7×24 Online