Welcome to the photo gallery of our products, then you will find the lightspot of various equipment, and enjoy yourself !

Toothed roller crusher vedio

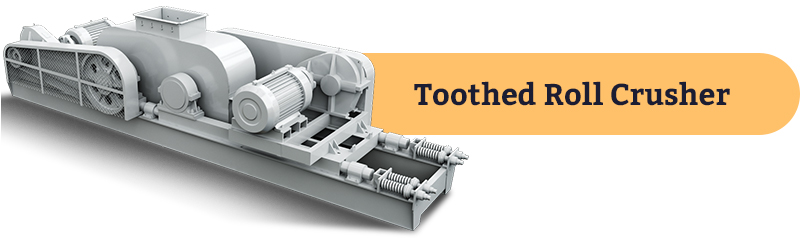

Toothed roll crusher is widely used in coal, metallurgy, mining, chemical industry, building materials, and other industries, and it is more suitable to crush coal in large coal preparation plant and process waste. Toothed roll crusher has a high crushing capacity. The distance between the rollers can be adjusted by hydraulic pressure. The bearing of the toothed roll crusher is centralization lubrication. What’s more, it has the advantages of optimal design, high efficiency, uniform grain, and low cost.

Protective device: The motor is connected with the retarder through hydraulic coupling to avoid dynamic overload. The sensor overload protection is very reliable. If you have mining project or chemical plant, the toothed roller crusher is prepared for you in China Fote.

The toothed roll crusher is suitable for crushing raw coal in coal mines, coal preparation plants and other industries (allowing less than 30% of coal gangue in raw coal). The crusher is also used to break other brittle materials whose hardness is similar to that of raw coal.

It has the characteristics of high efficiency, long life, full sealing, low noise, and uniform granularity. The double-toothed roll crusher is equipped with a scraper to keep the groove and working surface clean. For the toothed roll crusher, the outlet-size depends on the gap between the two rollers, the size of teeth, shape of teeth, and the number.

The characteristics of toothed roll crusher

The double-toothed roll crusher is relatively small in volume. It consists of two tooth rolls that are mounted in parallel and rotate in opposite directions. According to the crushing capacity and the size of the discharging granularity, the two crushing rolls are uniformly filled with brushing teeth.

And the double-toothed roll crusher adopts the operation way of non-circular, non-intermesh and non-uniform, which can enhance the contact face of roller teeth, and avoid material slippage and improve crushing efficiency.

When the toothed roller rotates, the teeth on the surface of the roller can bite the materials and crush them. Each roller crusher of the crushing system is driven by a separate motor. The roller crusher is generally driven by a belt, and it constitutes the deceleration system along with the reducing mechanism.

Working principle of toothed roll crusher

FTM double-tooth roller crusher for sand making, limestone, rock, clay crushing has a good crushing effect on wet and sticky materials. And adherence or clogging phenomenon never occurs during the work.

The silicon-aluminum raw material is an indispensable calibration material in the dry cement production process. After the mining work, the materials need to be crushed, transported and stored. and then they are sent to the raw material mill for grinding according to an appropriate ratio.

However, the silico-alumina raw materials have strong water storage capacity and high plasticity index, especially for bauxite and marlstone with water content more than 17% and plasticity index generally above 15. Because of the viscosity of materials, it can lead to blockage and arching during the process of crushing, transportation and storage, thus affecting the normal operation of the system.

Roller crusher process flow diagram

In order to solve the problem of adherence and clogging of wet-adhesive materials in the crushing stage, FTM toothed roll crusher is used to break the mixture of limestone and marl. In detail, firstly, the wet and dry materials are mixed and crushed, and secondly, the wet-adhesive materials and other limestone materials with lower moisture content are mixed into the crusher. And finally, they are crushed according to an appropriate ratio.

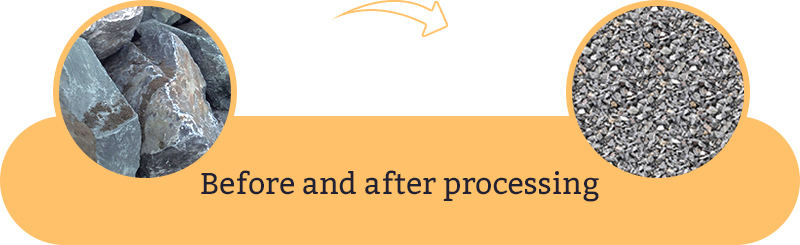

The processed material

There are some toothed roll crushers for sale, which manufactured by FTM heavy machinery. If you want more details, you can send an email or leave a message. We will be at your service.

The toothed roller crusher machine has advantages of small volume, large crushing ratio, low noise, simple structure, convenient maintenance, high productivity, uniform particle size of crushed material, low crushing rate, convenient maintenance, sensitive overload protection, safe and reliable.

| Model | Max. Feeding Size (mm) |

Discharging size(mm) |

Output (t/h) |

Motor power (kw) |

Total weight(t) |

| 2PGC600×500 | 200-450 | 15-100 | 30-60 | 4P 11×2 | 3.8 |

| 2PGC600×800 | 300-600 | 20-120 | 60-100 | 4P 18.5×2 | 7.2 |

| 2PGC800×1000 | 500-800 | 30-150 | 100-160 | 4P 22×2 | 12.6 |

| 2PGC1000×1000 | 700-950 | 30-200 | 150-200 | 6P 45×2 | 18.8 |

| 2PGC1200×1200 | 800-1050 | 30-200 | 180-250 | 6P 55×2 | 29.5 |

| 2PGC1500×1200 | 1000-1150 | 30-200 | 200-300 | 6P 75×2 | 38.6 |

| Model | Max. Feeding Size (mm) |

Discharging size(mm) |

Output (t/h) |

| 2PGC600×500 | 200-450 | 15-100 | 30-60 |

| 2PGC600×800 | 300-600 | 20-120 | 60-100 |

| 2PGC800×1000 | 500-800 | 30-150 | 100-160 |

| 2PGC1000×1000 | 700-950 | 30-200 | 150-200 |

| 2PGC1200×1200 | 800-1050 | 30-200 | 180-250 |

| 2PGC1500×1200 | 1000-1150 | 30-200 | 200-300 |

| Model | Roller diameter (mm) |

Roller length (mm) |

Max. Feeding Size (mm) |

Discharging size(mm) |

Output (t/h) |

Motor power (kw) |

Total weight(t) |

Overall dimension (L×W×H) (mm) |

| 2PGC600×500 | 600 | 500 | 200-450 | 15-100 | 30-60 | 4P 11×2 | 3.8 | 2450×1800×950 |

| 2PGC600×800 | 600 | 750 | 300-600 | 20-120 | 60-100 | 4P 18.5×2 | 7.2 | 4500×1900×1350 |

| 2PGC800×1000 | 800 | 1000 | 500-800 | 30-150 | 100-160 | 4P 22×2 | 12.6 | 2550×2050×1100 |

| 2PGC1000×1000 | 1000 | 1000 | 700-950 | 30-200 | 150-200 | 6P 45×2 | 18.8 | 2780×4100×1550 |

| 2PGC1200×1200 | 1200 | 1200 | 800-1050 | 30-200 | 180-250 | 6P 55×2 | 29.5 | 2780×3200×1980 |

| 2PGC1500×1200 | 1500 | 1200 | 1000-1150 | 30-200 | 200-300 | 6P 75×2 | 38.6 | 8010×4500×2050 |

| Model | Max. Feeding Size (mm) |

Discharging size(mm) |

Output (t/h) |

| 2PGC600×500 | 200-450 | 15-100 | 30-60 |

| 2PGC600×800 | 300-600 | 20-120 | 60-100 |

| 2PGC800×1000 | 500-800 | 30-150 | 100-160 |

| 2PGC1000×1000 | 700-950 | 30-200 | 150-200 |

| 2PGC1200×1200 | 800-1050 | 30-200 | 180-250 |

| 2PGC1500×1200 | 1000-1150 | 30-200 | 200-300 |

Contact

E-mail:vip@sinoftm.com

Address: No.168 Wutong Street, High-Tech Industrial Development Zone of Zhengzhou City, China.

Hot Products

Future Prospect

We would like to cooperate with customers all around the world, and welcome you sincerely !

Inquiry Online 7×24 Online