Welcome to the photo gallery of our products, then you will find the lightspot of various equipment, and enjoy yourself !

Compound crusher can be classified into glass crusher, gypsum crusher machine, small stone crusher, and vertical crusher. Compound crusher is widely used to crush shale, glass, ceramics, bluestone, metal ores, cement raw meal, clinker in building sand, iron ore, sandstone, gypsum, coal gangue, coal, etc. Especially in sand making and metal or stone, compound crusher is most widely used crushing machine.

Compound crushers

Compound crushers combine the advantages of tertiary crusher and coarse grinding mill. This equipment works efficiently, has the unique structure, and can easily replace consumables. It can be used for the crushing of various stone materials and metallurgical slags, which is a crushing machine without the sieve. Fote company, the compound crusher factory, can provide you with the best after-sale service. Welcom to our company for a visit.

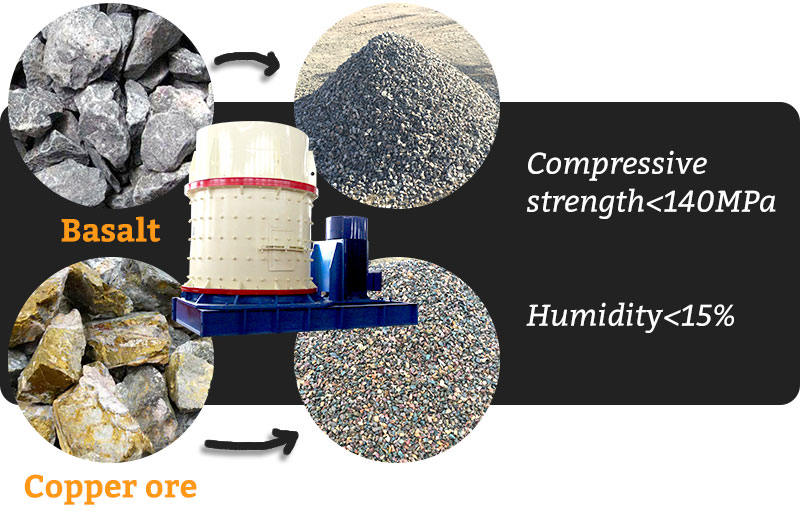

Compound crusher is widely used in various ores, cement, refractory, aluminum from bauxite, carborundum, glass raw materials and other materials. In mechanism building sand and stone, as well as a variety of metallurgical slag crushing, compound crusher is generally used and yield high efficiency compared with other types of crushers. The compressive strength of raw materials does not exceed 140 MPa and the humidity is not more than 15%.

Applicable raw materials of compound crusher

Large crushing ratio.

Discharge particle size is adjustable.

No influence of hammer and impact plate bearing; no grating. When crushing the materials with high water content and mud content, it is not easy being blocked.

It adopts an elastic adjusting mechanism so that the non-crushing materials can be discharged automatically without damage the machine.

The bearing is in horizontal layout and has a long life span.

Compound crusher can crush high-temperature materials (like cement clinker).

The rotor of compound crusher has a special structure and when crushing the materials, and there is barely abrasion for the rotor.

The rock materials are fell from the feed hopper into the tray on the cutting chamber and throw the material to the inner wall of the cylinder by the centrifugal force of tray. The rock materials constantly collide with the counter-attack plate installed on the inner wall, resulting in a large number of hairline cracks. After the material enters the conical rotor cavity, it falls spirally in the conical space, and the existing ore is further crushed, thereby the crushing efficiency is improved.

The material falling from the conical rotor cavity enters the lower crushing chamber to further crush the material into small particles by the centrifugal force of the drip tray. Then, the crushed products will be put into the cylindrical rotor cavity and be grinded further until the granularity is proper.

Working principle of compound crusher

With the development of high-speed railway, the market for the compound crushers has become larger and larger. The building of high-speed railway has a high demand for sandstone aggregate and concrete aggregate, while there are many manufacturers that produce compound crusher for sale. FTM Machinery actively introduced foreign technology to improve the quality of compound crushers of china. The compound crusher has been widely installed in the construction of high-speed railway and highway, and it’s the essential equipment of national infrastructure.

When processing the basalt or coal, the compound crusher usually used as the primary crusher, and the impact crusher will shape it, which can reduce the needle-like content of stone to about 4%. In accordance with the process of high-speed railway construction across the country, we have prepared for serving the whole country and maintained close cooperation with key engineering units in various provinces and cities across the country. Therefore, the future use of compound crusher is still booming.

Although there are many compound crusher manufacturers, The price of compound crusher manufactured from FTM Machinery is cheap and reasonable. Many customers from other countries visited and bought our compound crusher. If you are interested in our compound crusher, welcome to leave a message on the message board.

Coustomers are visiting the compound crusher machine

| Specification | Capacity(t/h) | Power(kw) |

| 800 | 5-15 | 4P 30 |

| 1000 | 10-30 | 4P 55 |

| 1250 | 17-60 | 6P 132 |

| 1500 | 25-80 | 8P 160 |

| 1750 | 30-100 | 8P 200 |

| Specification | Capacity(t/h) | Power(kw) |

| 860 | 5-15 | 4P 30 |

| 1060 | 10-30 | 4P 55 |

| 1260 | 17-60 | 6P 132 |

| 1560 | 25-80 | 8P 160 |

| 1760 | 30-100 | 8P 200 |

| Specification | Capacity(t/h) | Power(kw) |

| 860 | 5-15 | 4P 30 |

| 1060 | 10-30 | 4P 55 |

| 1260 | 17-60 | 6P 132 |

| 1560 | 25-80 | 8P 160 |

| 1760 | 30-100 | 8P 200 |

Contact

E-mail:vip@sinoftm.com

Address: No.168 Wutong Street, High-Tech Industrial Development Zone of Zhengzhou City, China.

Hot Products

Future Prospect

We would like to cooperate with customers all around the world, and welcome you sincerely !

Inquiry Online 7×24 Online