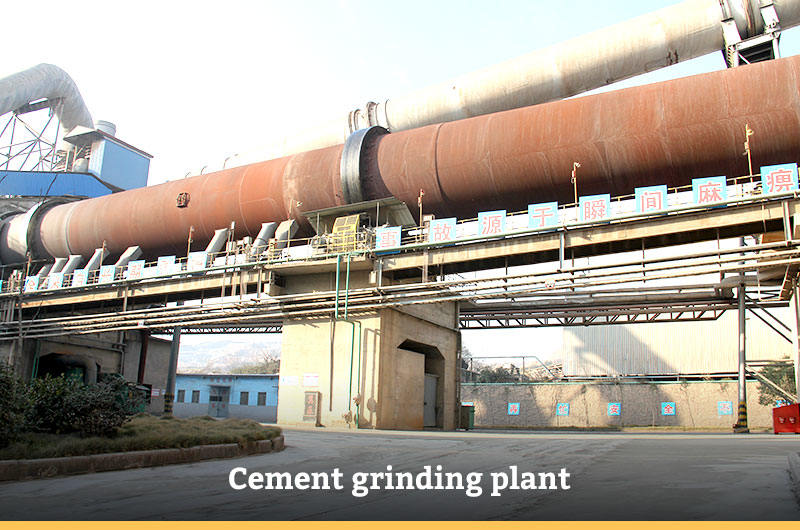

The cement grinding plant also named the cement grinding station or the cement clinker grinding plant is the production unit of the cement production line’s last period in which both the cement clinker and other mixed materials are ground to be finished cement products.

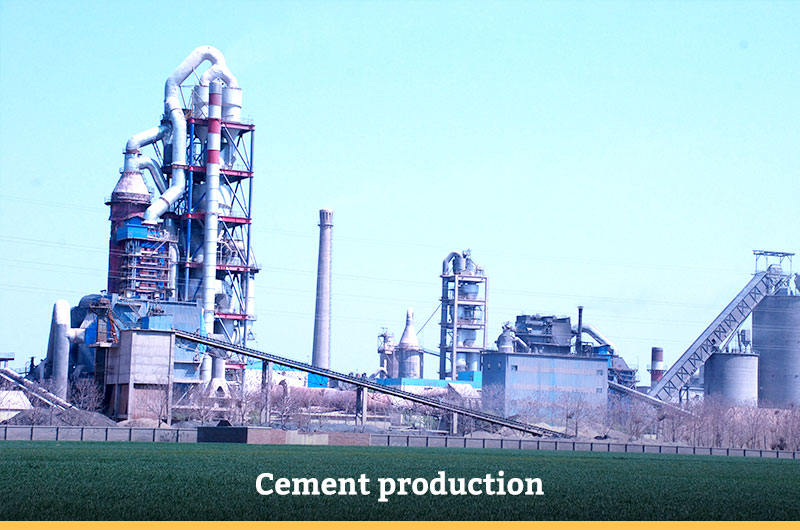

Cement grinding station is the finished cement product production unit formed by separately out of the final stage in the production of cement. At this stage, cement clinker fixes with a moderate amount of mixed materials to be ground together, producing the cement. The production of cement can generally be divided into three processes: raw material preparation, clinker calcination, and cement production. The process of silicate cement is representative of cement production.

compact cement clinker grinding plant

Using limestone and clay that are crushed, Ingrediented, and grinded by the machine to make the raw material, and the raw material will be calcined into clinker in the cement kilns. Grinding clinker with an appropriate amount of gypsum (sometimes mixed with mixed materials or admixtures).

The cement production process can be divided to three periods: preparation of raw materials, calcination of clinker and cement grinding. The silicate cement production uses the limestones as the main raw materials and after the addition of other mixture, the limestone is roasted at high temperature and then forms the cement clinker which is ground with the mixture of gypsum and other mixing agents by the cement grinding plant to become finished cement products.

Cement/clinker production process

It attributes to the environmentally friendly cement grinding plant process. After many times of technological improvement, FTM Machinery turns the discharging wastes into treasure as the cement batching.

As we all know, the normal cement or clinker grinding unit process will discharge out the industrial solid wastes like furnace slag, fly ash, desulfurization gypsum, water slag, etc, which can seriously damage the environment. Based on that, FTM engineers upgrade the discharging way and place the solid wastes in different batching bins, then along with the clinkers at a certain proportion, they are conveyed to cement mills (or ball mills in cement plant) for being milled into different levels of cement.

Along with the changes occurring, cement grinding unit costs can be saved a lot. As estimated, every year, almost 500,000 tons of waste slags are recycled for cement production. Except for the manufacturing work of compact cement grinding plant, FTM Machinery (Fote) can also manufacture the small cement grinding plant, or mini cement grinding plant.

Cement grinding unit in UAE

The cement grinding plant is generally built near the cement sales market in order to decrease the transportation cost. The cement grinding station produces the finished cement products by grinding the mixture of cement clinker, gypsum, cinder, and coal ash with a proper proportion.

The cement grinding is an energy-intensive process, so when it comes to the selection of the cement grinding plant, we should consider the one with high grinding efficiency and low energy consumption, thus increasing the economic benefit of the enterprise. It’s better to simplify the cement grinding unite process, reduce the construction area and save the investment cost.

Fote is specialized in manufacturing large-sized cement grinding equipment including cement mill, cement ball mill, cement rotary kiln and cement cooling machine, etc. For more information about our products, please leave a message and contact us.

Cement grinding plant

The layout of cement production is to build a cement clinker production line in the mining area. And the cement grinding mill should be built near the market of cement so that can reduce the cost of transportation. If the clinker production plant is built around the city, which will increase the cost of transportation by 60%.

However, if the cement grinding station and the clinker production line are built together in the mine, since most of the mixed materials are waste generated by the city, and these mixed materials are transported to the cement factory built near the mine, the ground into cement and then transported to the city, which increases transportation costs.

cement mill grinding plant with low cost build-up

Therefore, the clinker production line should be built near the mine, and the cement grinding station should be built near the market. FTM Machinery, as the cement grinding company, is a green industry.

Contact

E-mail:vip@sinoftm.com

Address: Tanxiang Road, High-Tech Industrial Development Zone of Zhengzhou City, P. R. China.

Hot Products

Leave your personal information(Only kept by FTM), for sending a favorable price meets your production budget.

Inquiry Online 7×24 Online