By: Ashley March 20, 2020 Last Updated :March 20, 2020

There are several classification methods for grinding machines. Among them, the more commonly used one is to divide them according to different grinding media: whose media is metal balls is called the ball mill, steel rods the rod mill and the ore itself the autogenous mill (AG mill). In order to improve the processing capacity of the AG mill and reduce power consumption, a small number of steel balls can be added to form a semi-autogenous mill (SAG mill). This article introduces the differences between ball mills, rod mills and SAG mills.

Different grinding media is a significant difference between these three kinds of mills. Not only the types of media, but also the charge ratio is different. The following table gives a brief summary:

| Types of mill | Ball mill | Rod mill | SAG mill |

| Types of media | Metal balls | Steel rods of 50-100mm | 3% of steel balls (φ80~φ120) |

| Charge ratio | 40%-50% | 35%-45% | 8%~12%/15% |

different grinding media of ball mills, rod mills and SAG mills

The biggest feature of SAG mills is the large crushing ratio, which can crush and grind the materials to 0.074mm at one time, accounting for more than 20% to 40% of the total product. The crushing ratio can reach 4000 ~ 5000, which is more than ten times higher than that of the ball mill machine and rod grinding machine.

Ball mill:Ball mills are the most widely used one.

Rod mill:The rod mill has the highest efficiency when the feed size is <30mm and the discharge size is about 3mm with uniform particle size and light overcrushing phenomenon.

SAG mill: When the weight of the SAG mill is more than 75%, the output is high and the energy consumption is low with a light degree of over-crushing.

| Types of mill | Ball mill | Rod mill | SAG mill |

| Types of material | Almost all materials | 1.Rough grinding 2.Brittle materials, such as tungsten, tin ore before gravity concentration |

Dry SAG mill: asbestos mine, silicon carbide, etc. Wet SAG mill: minerals with mud (can omit ore washing) |

| Feeding size | ≤25mm | ≤50mm | 300-400mm |

| Capacity | 0.62—180t/h | 0.65—615t/h | 1.5-338t/h |

| Discharging size | 0.074—0.89mm | 0.147—0.833mm | <20mm |

Taking quartz as an example, the following table shows the specific situation of quartz stone when using these three kinds of grinding machines:

quartz after grinding

| Parameters | Items | Ball mill | Rod mill | SAG mill |

| Mill | Inner diameter (mm) | 200 | 200 | 520 |

| Length (mm) | 184 | 280 | 225 | |

| Volume (cm3) | 5776 | 8792 | 31156 | |

| Speed | Critical speed (rpm) | 102 | 102 | 71.5 |

| Operational speed (75% of critical speed) (rpm) |

76 | 51 | 28 | |

| Media | Material | Stainless Steel | Steel Rods | Lump Ore |

| Diameter(mm) | 30,26 | 29,24,19 | -80+50 | |

| Average media weight (g) | 118.18,68.19 | 1521, 1041, 669 | / | |

| Specific gravity (g/cm3) | 7.9 | 7.9 | / | |

| Fractional Media filling (JB) | 0.2 | / | / | |

| Total mass (kg) | 5.475 | 22.6 | 3 | |

| Material | Specific gravity (g/cm3) | 2.65 | 2.65 | 2.65 |

| Total powder weight (g) | 367.3 | 745.5 | 2000 | |

| Fractional powder filling (fc) | 0.04 | / | / | |

| Powder-media loading ratio (U) | 0.5 | / | / | |

| Feed size (μm) | -800+600 | -4750+3350 | -10000+1000 | |

| Grinding time | Optimum time(min) | 16 | 16 | 256 |

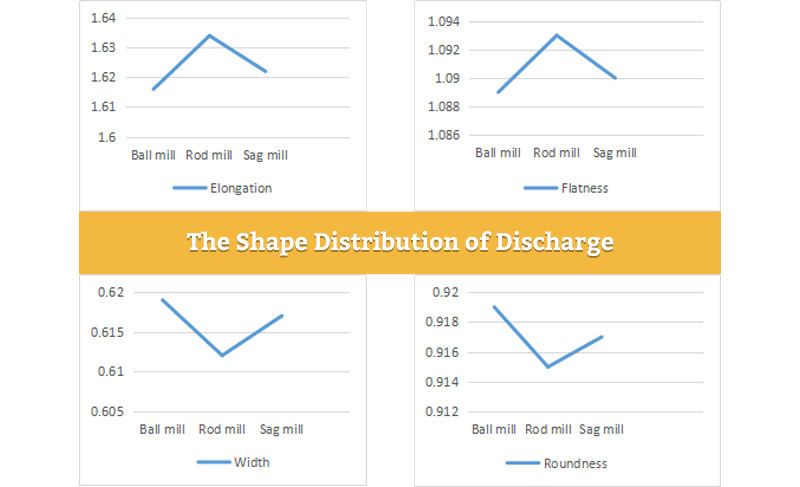

The discharging shapes of different mills will be different. As shown in the following figure, the length and flatness value of rod mill discharge are higher, while that of the ball mill is the opposite. The roundness and width value of ball mill discharge is higher, and rod mill is in contrast. That is, the discharge of the ball mill is more round and the rod mill longer.

The Shape Distribution of Discharge

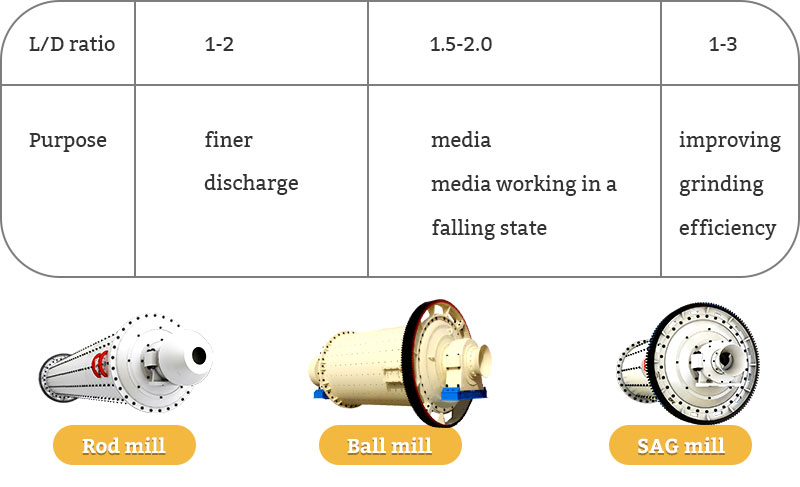

These three types of grinding equipment have different length-diameter ratios, that is, different L/D ratios.

L/D ratios of ball mills, rod mills and SAG mills

Besides, the diameter of the hollow shaft at both ends of the barrel of the SAG mill is large and the length is short. The diameter is large for its large feeding size. Generally, the inner diameter of the hollow shaft is about 2 times of the larger ore feeding size, which is about 0.2-0.3 times of the inner diameter of the ball mill. The short length is for the higher speed of the flow of ore.

The internal structures of the ball mill, rod mill and SAG are different. The following table analyzes the feeding part, bearing part, rotary part, liner shape, transmission part and slow transmission device:

| Types of mill | Ball mill | Rod mill | SAG mill |

| Feeding part | Trolley type welding chute structure | / | Trolley type welding chute structure |

| Bearing part | Hydrostatic Bearings | Plain self-aligning bearing | Dynamic-static pressure bearing |

| Rotary part | The end cap and hollow shaft can be integrated or split. | / | The end cap made of steel is welded into the cylinder body. |

| Liner shape | Waveform, convex shape, lap shape and scalariform, etc. | Waveform, scalariform, or wedge | Strip liner and T-shaped lifting liner |

| Transmission part | Large gear: combined on the barrel Small one: cast iron base |

Large gear: connected to the barrel Small one: connected to the input shaft of the reducer. |

Large gear: fixed on the hollow shaft of the discharge. |

| Slow transmission device | Equipped with rack and pinion structure. The operating handle is far away from the barrel. |

/ | Located above the claw clutch High labor intensity of lifting the clutch |

liners of ball mill, rod mill and SAG mill

SAG mill: The SAG mill adopts a self-return device to realize the discharge of the mill.

Ball mill: There are many types of ball mills, mainly including overflow ball mills and grate ball mills.

Rod mill: The rod mill does not use grid plates to discharge ore. There are only two types: overflow type and open-mouth type. The diameter of the hollow shaft at the discharge end is generally larger than that of a ball mill of the same specification.

There are so many differences between ball mills, rod mills and SAG mills. How should we choose in specific applications?

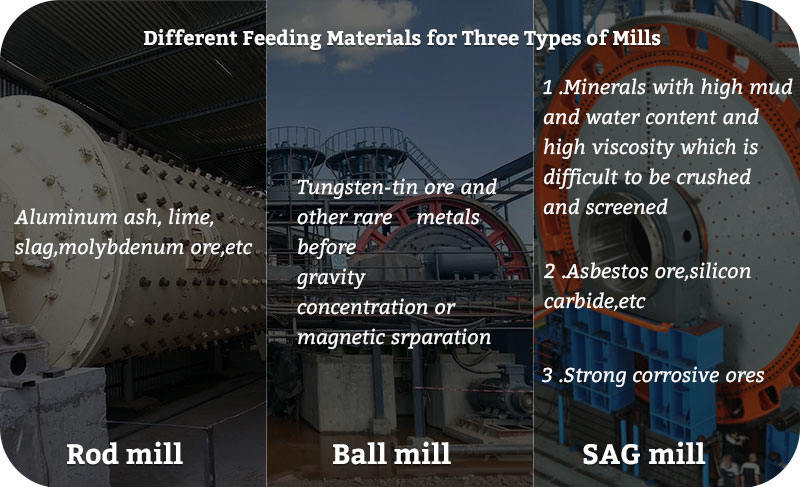

According to Raw Materials

Different mills should be selected for different raw materials.

Different Feeding Materials for Three Types of Mills

According to the size of finished products

Rod mill: When the particle size of the product is 1-3mm, the processing capacity of the rod mill is greater than that of a ball mill of the same specification.

Ball mill: When the particle size of the product is less than 0.5mm, the grinding effect of the ball mill is greater than that of a rod mill of the same specification.

SAG mill: The SAG mill has a wide range of feeding particle sizes and can process larger minerals, but at the same time, its output particle size is relatively larger.

According to the Grinding Stage

| Types of mill | Ball mill | Rod mill | SAG mill |

| Advantages | 1.Strong production capacity 2.Fine discharging size |

1.Uniform particle size 2.Simple configuration and low cost |

Wide range of feeding size and large crushing ratio |

| Disadvantages | 1.Higher cost 2.Be prone to overcrushing |

1.Rough output products 2.Poor grinding efficiency |

1.Large output granularity 2.Inconvenient installation and maintenance |

| Grinding Stage | After fine grinding (first-stage grinding: grate ball mill; second-stage grinding: overflow ball mill) |

1. First-stage grinding 2.Fine grinding instead of short-head cone crusher for viscous ores |

Equivalent to “crushing + first-stage grinding” |

a ball mill working on site

According to the Mode of Production

Rod mill: In order to prevent the damage caused by overcrushing, the rod mill is often used for production and processing before gravity concentration or magnetic separation plant.

Ball mill: Ball mills are mostly used in the production and processing of cement plants.

SAG mill: SAG mills are less commonly used in small and medium-sized plants because generally larger diameter SAG mills will play a role.

Latest blog

By:AshleyMarch 14, 2020

By:AshleyMarch 14, 2020

By:AshleyDecember 28, 2019

By:AshleyDecember 28, 2019

By:AshleyDecember 20, 2019

By:AshleyDecember 20, 2019

By:AshleyDecember 14, 2019

By:AshleyDecember 14, 2019

Contact

E-mail:vip@sinoftm.com

Address: No.168 Wutong Street, High-Tech Industrial Development Zone of Zhengzhou City, China.

Hot Products

Future Prospect

We would like to cooperate with customers all around the world, and welcome you sincerely !

Inquiry Online 7×24 Online