Welcome to the photo gallery of our products, then you will find the lightspot of various equipment, and enjoy yourself !

Stone crusher, main function is to crush large stones and rocks into smaller and more uniform size. It is a heavy-duty mechanical equipment widely used in mining, construction, roads, bridges and other industries. We have small, medium and large stone crushers, different models to meet your crushing needs.

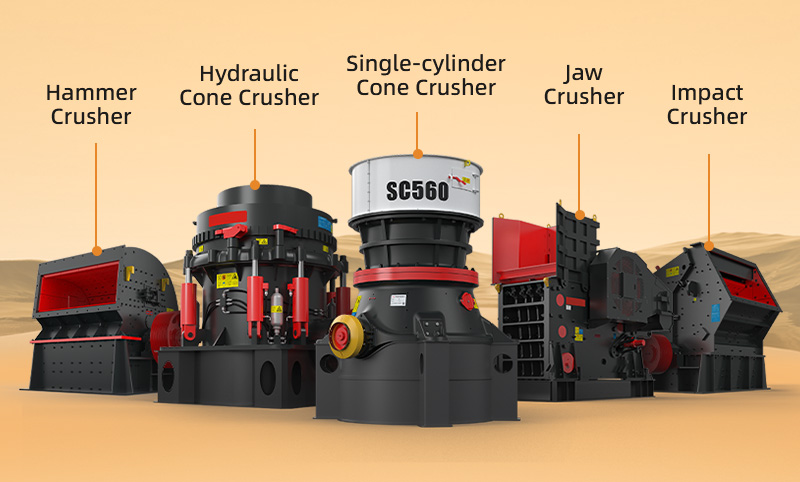

Some stone crushers

The stone crusher can handle materials of various hardnesses, including but not limited to various rocks, ores, granite, basalt, limestone, marble, river pebbles, cobbles, bluestone, gangue, dolomite, calcite, quartzite, etc.

Partially applied materials

1.Strong crushing ability: The stone crusher adopts advanced crushing technology and efficient crushing chamber design, which can quickly break large materials into the required particle size, greatly improving production efficiency.

2.High output and stable operation: high production efficiency and large output. It has simple structure and convenient operation and maintenance.

3.Wide scope of application: used for crushing various materials, with complete models, Professional crushing solutions can be specified according to needs.

Common types of stone crushers include: jaw crusher, impact crusher, cone crusher, roller crusher, hammer crusher, compound crusher, single-stage crusher ect.

Working principle: Jaw crusher mainly crushes materials under the squeezing action between two jaws. The material is squeezed, split and bent by the movable jaw plate in the crushing cavity, thereby achieving the crushing of the material.

Hot selling models: PE 400X600, PE 600X900, HD86, HD72

Advantage:The jaw crusher adopts advanced crushing technology, which can quickly and effectively break large materials into the required particle size, greatly improving production efficiency and achieving a higher crushing ratio.

Jaw crusher

Working principle:Impact crusher is a crusher that uses a hammer or plate hammer on a high-speed rotating impeller to impact, throw, collide, and rub materials to achieve crushing purposes.

Hot selling models: CJ1110, CJ1213, PF1007

Advantage:The structure of the impact crusher is relatively simple, and subsequent maintenance is relatively convenient. In addition, during the working process of the impact crusher, materials collide and crush each other, so there is less wear and tear on the machine itself.

Impact crusher

Working principle:Cone crusher uses the lamination principle to crush stone. Continuously roll the wall membrane onto the broken walls, squeezing the stone between them.

Hot selling models: PSG1300, HPM200, HPM300

Advantage:The cone crusher adopts high-strength materials and advanced design, which makes it have excellent wear resistance and durability and can operate stably for a long time. Its structure is relatively simple, and its operation and maintenance are very convenient.

Cone crusher

Raw material: granite, basalt and other hard ores

Capacity: 500T/H

We recommend PE1500×1800 jaw crusher to our customers based on their needs.

Customer feedback:”I was impressed with the strong crushing capacity of this jaw crusher.I was surprised that it could achieve both high output and high quality at the same time, meeting all the requirements for the size of the aggregates. In addition, we received prompt and effective solutions to any problems we encountered during the usage process. There is no need to worry at all, as the after-sales service is excellent.”

Jaw crusher working site

Raw material: construction waste

Capacity: 200T/H

Customer feedback:”As a construction company, we needed a crusher to handle construction waste. Fote’s engineers provided us with a crushing solution that utilized an impact crusher. This machine’s unique enclosed design effectively controls dust and noise, making it an excellent choice. Additionally, its unique casing design allows me to complete routine inspections in just a few minutes.”

construction waste crushing work site in US

The price of stone crusher depends on your model choice or your project plan. However, as a manufacturer and supplier of stone crushers with a long history of more than 40 years, our machines are all sold directly from the factory, 100% factory price.

In order to ensure the efficient operation of your stone crusher and extend the life of the equipment, we provide a one-step after-sales service system covering the following key links:

Professional installation and commissioning—Operator training—Regular maintenance—Quick supply of original parts—24/7 technical support—Upgrade service—Maintenance and repair plan—Environmental compliance

Contact us to start an exclusive after-sales service journey. If you want to know the price, pictures or specifications PDF of the stone crusher, please leave us a message. Our FTM mechanical engineers will recommend the most suitable crusher for you based on your needs.

Contact

E-mail:vip@sinoftm.com

Address: No.168 Wutong Street, High-Tech Industrial Development Zone of Zhengzhou City, China.

Hot Products

Future Prospect

We would like to cooperate with customers all around the world, and welcome you sincerely !

Inquiry Online 7×24 Online