Welcome to the photo gallery of our products, then you will find the lightspot of various equipment, and enjoy yourself !

Tertiary stone crusher, manufactured from Henan Fote Machinery Ltd., is especially suitable for making abrasive, refractory, cement and crushing quartz sand, steel sand, slag powder, copper ore, etc. There are different types of tertiary crushers like tertiary impact crushers and tertiary cone crushers.

Mining tertiary crusher is an efficient, energy-saving crushing equipment that can save energy 50% than traditional crushers. The tertiary stone crusher is also be called fine crusher. As the name suggests, it is a crusher for fine crushing and always used after coarse crushers like concrete jaw crushers and secondary crushers like impact crushers and cone crushers.

Applied raw materials

1.The fine crusher is designed by seesaw and can crush the hard materials, which improve the crushing efficiency a lot.

2.The crusher runs fast, saves electricity, and reduce consumption.

3.Fragile parts are made by hard-wearing materials so the tertiary stone crusher can be used for a long time.

The fine crusher has stable operating performance, simple process, simple structure, and is easy to maintain. Its hammerhead has a long life and its capacity is very large.

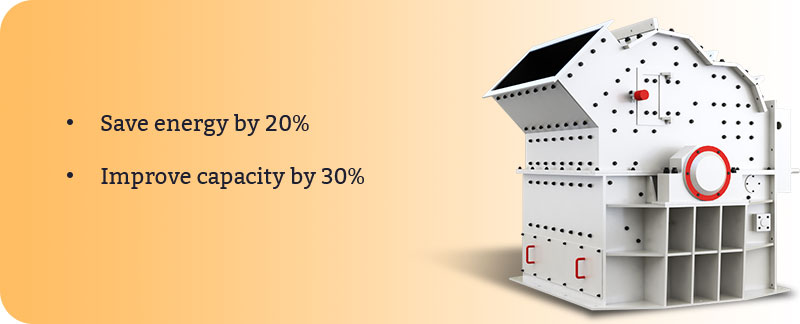

Compared with traditional stone crushers, fine crusher saves 20% energy, works stably. In terms of production capacity, the tertiary crusher no matter what tertiary roll crushers or tertiary impact crushers can improve by 30% compared to the traditional crusher of the same size.

Besides, the operation and maintenance costs are also lower than the common crusher. Thus, investing and buying tertiary crusher is quite cost-effective.

The materials discharged from the tertiary crusher are finer. However, its capacity is lower than common crusher. Therefore, customers can choose the suitable equipment according to different demands on the production line.

Tertiary crusher VS common crusher

The tertiary stone crusher is a kind of heavy machinery which works cyclically. When the tertiary crusher is working, the rotor driven by the motor rotates at a high speed. And the raw materials are put into the first crushing cavity and impact with the hammer on the rotor.

Then, the materials impacted in the first chamber will be put into the second cavity, and be discharged from the outlet. In a world, the tertiary crusher repeats the operating above all to crush the stone materials.

Working principle

The hammer of the tertiary crusher is an indispensable part of the stone crusher, including the wear-resistant parts. Most of the hammer parts produced by FTM Machinery use high-manganese steel. When the Henan Fote company is processing crushing equipment, the element is added to the high-manganese steel. The hammer of the tertiary crusher can be greatly strengthened. When crushing iron ore with a tertiary crusher, the service life of the China Fote Machinery hammer is higher than that of ordinary high manganese steel.

Although powerful performances of the tertiary crushers, it still need to team up with other crushers like primary jaw crushers, secondary cone crushers and impact crushers to implment the whole crushing process.

China Fote has high-quality mining equipment but cheap price. And the machines have a long life. Our experts will offer you a professional plan according to your needs. We will arrange workers to install and train the precautions for you at the site. We also have remote online service. If you want to know more, please leave your message on our website and our manager will contact you within 24hours and send you the latest quotation.

| Model | Rotor diameter×width(mm) | Limestone(t/h) | Power(kW) |

| pxJ0804 | 800×400 | 5-45 | 37 |

| pxJ0806 | 800×600 | 7-55 | 45 |

| pxJ0808 | 800×800 | 10-65 | 45 |

| pxJ1010 | 1010×1010 | 15-75 | 55 |

| pxJ1212 | 1200×1200 | 20-110 | 110 |

| pxJ1414 | 1400×1400 | 25-150 | 160 |

| pxJ1616 | 1600×1600 | 30-200 | 250 |

| pxJ1818 | 1800×1800 | 40-260 | 315 |

| Model | PXJ0804 | PXJ0806 | PXJ0808 | PXJ1010 | PXJ1212 | PXJ1414 | PXJ1616 | PXJ1818 |

| Rotor diameter×width(mm) | 800×400 | 800×600 | 800×800 | 1010×1010 | 1200×1200 | 1400×1400 | 1600×1600 | 1800×1800 |

| Limestone(t/h) | 5-45 | 7-55 | 10-65 | 15-75 | 20-110 | 25-150 | 30-200 | 40-260 |

| Power(kW) | 37 | 45 | 45 | 55 | 110 | 160 | 250 | 315 |

Note:processing Capacity May Vary With Different Materials And Feeding Sizes.

| Model | Rotor diameter×width(mm) | Limestone(t/h) | Power(kW) |

| PXJ0804 | 800×400 | 5-45 | 37 |

| PXJ0806 | 800×600 | 7-55 | 45 |

| PXJ0808 | 800×800 | 10-65 | 45 |

| PXJ1010 | 1010×1010 | 15-75 | 55 |

| PXJ1212 | 1200×1200 | 20-110 | 110 |

| PXJ1414 | 1400×1400 | 25-150 | 160 |

| PXJ1616 | 1600×1600 | 30-200 | 250 |

| PXJ1818 | 1800×1800 | 40-260 | 315 |

Note:processing Capacity May Vary With Different Materials And Feeding Sizes.

Contact

E-mail:vip@sinoftm.com

Address: No.168 Wutong Street, High-Tech Industrial Development Zone of Zhengzhou City, China.

Hot Products

Future Prospect

We would like to cooperate with customers all around the world, and welcome you sincerely !

Inquiry Online 7×24 Online