By: Ashley July 27,2019 November 11,2024

“I’m Ahmed from India. I see your company sell the briquette machine. I have coal to be transported, used, and packaged. How much is the briquette machine 75 tones per hour?”. This is the message from an Indian customer. If you have a coal project and need the machine, welcome to leave a message on our website.

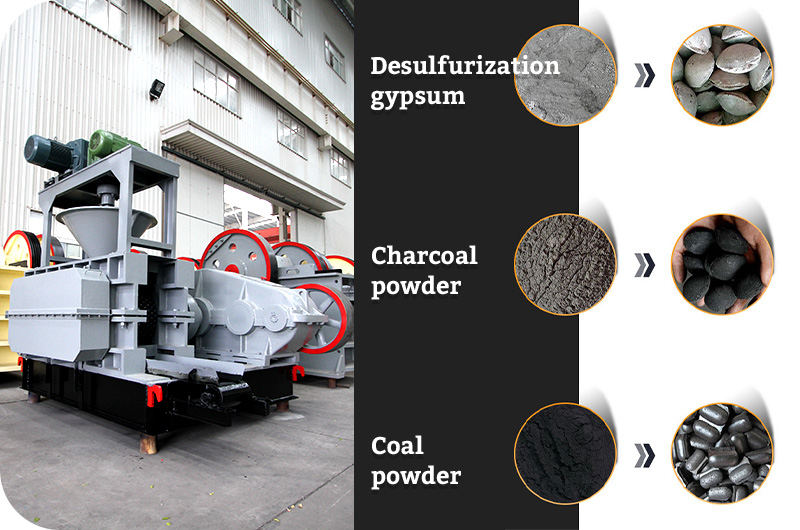

We not only have the coal briqutte machine, but also have the desulfurization briquette press, mineral powder briquette equipment and dry powder high pressure briquette machine. Mineral powder briquette equipment is mainly used to process colored and ferrous metal ore powder. And the pressed mineral powder will be smelt in the stove to improve the added value. Any metallurgical industry waste, auxiliary materials are all needed to be processed via the briquette machine.

Dry powder high pressure briquette machine is mainly used for material ball compaction without moisture, such as lime powder, magnesium oxide powder, copper powder, chrome ore powder, lead and zinc scrap, etc. These materials are processed into briquettes through the high pressure briquette equipment, which is widely used in the fields of mentallury, chemistry and refractory.

In the “low carbon” environment, the environmentally friendly mental briquette machine is compliant. China briquette machine is used to press the pulverized coal, iron powder, coking coal, aluminum powder, iron filings, iron oxide scale, carbon powder, carbon powder, slag, gypsum, tailings, sludge, kaolin, activated carbon, coke and other powders, powders, waste, which is widely applied in the fields of refractory, power plant, metallurgy, chemical, energy, transportation, and heating.

The material processed by the coal briquette machine is energy-saving and environmental protection, easy to transport, which improves the utilization rate of waste, and has good economic and social benefits. The dry powder briquette machine is mainly used for the ball making of colored and ferrous metal ore powder, directly into the furnace for smelting, and increasing the added value. The metallurgical industry waste, auxiliary materials need to be on the furnace all need to be pressed through the briquette machine, such as dust ash, pool mud, scale, steel slag, iron powder, aluminum ash powder, silico-manganese powder, etc.

Appliable materials of briquette machine

Transfer power to two rollers simultaneously via the gearbox and turn the two rollers in phase. In the rotation of the two rollers, the material enters the ball mold. With the rotation of the roller, the material will withstand different pressures. When the material is rotated to the contact point of two rolls, the material is subjected to the highest pressure. Under the great pressure, the material is processed into a ball that’s why it is also called charcoal briquette press machine.

In order to meet the molding needs, adjust the speed with hand through the electromagnet speed control motor. The clients can adjust the rotating speed of the briquette machine according to the needs to achieve the highest ball making rate and largest capacity. The pressed materials then go through the screening machine, and the qualified ones will be packed, the unqualified materials will be pressed again with the new material.

In addition to desulfurization gypsum, the production of phosphate fertilizer also produces a large amount of phosphogypsum. Each ton of phosphate fertilizer will produce 5 tons of phosphogypsum. The chemical properties between phosphogypsum and desulfurization gypsum are familiar. Poor handling of these industrial by-products will cause serious secondary pollution. At this time, the role of the desulfurization gypsum briquette machine is reflected.

The industrial desulfurization gypsum can be made into cement retarder. The desulfurization gypsum briquette machine is to press this gypsum into balls to facilitate transportation, use, and improve the utilization of desulfurization gypsum.

Previously, industrial gypsum occupied land had caused potential threats to the environment. However, this problem has been solved after the appearance of briquette machine. Desulfurization gypsum briquette machine has solved the problem of transportation and utilization, which not only reduces the exploitation of natural gypsum but also realizes secondary utilization and has extremely high economic and social benefits. The desulfurization gypsum ball press plays an important role in it.

Thermal power plant

FTM Machinery uses the mechanical method to press the coal into briquette. Such briquettes can improve combustion efficiency, reduce environmental pollution, expand the application range of high-volatility weakly cohesive coal such as lean coal, gas coal, long flame coal, and lignite, and rationally utilize coal resources.

The length briquettes used in the field of chemistry is usually 35~50mm. The anthracite or tar whose size is lesson than 3mm or the powdered brown coal whose yield is more than 10% can be pressed into balls, which is mainly used fertilizer gas, semi-coke, liquid or gaseous fuels and production of chemical products such as methanol and acetic acid.

The coal briquettes that are used as a steam locomotive has shapes of oval and drip. The development of briquets coal needs to solve the thermal deformation characteristics of the combustion process using temperature control. Using batching technology to help solve key technologies for improving coal quality and the melting point of coal ash. For coal with high sulfur, it is necessary to use catalytic reverse equilibrium to increase the conversion rate of sulfur to reduce pollution.

The coke is formed by a weakly cohesive pulverized coal, coking in a continuous coke oven, or using a high-speed thermal analysis of the colloidal body to achieve hot pressing coke formation. The development of coke can expand coking raw materials and improve its oven efficiency. Most manufacturers use binder low-pressure molding to produce industrial briquette. Most of the binder is lime, petroleum asphalt, tar pitch or pulp waste. The amount of binder depends on the comeliness of the coal, and is generally about 5-10%.

Coal briquettes with high burning value

In addition to ordinary honeycomb coal briquettes, many manufacturers have begun to develop ignitable briquettes for heating and coal-fired briquettes for household cooking. The structure and raw material formula of this type of coal briquettes are more complicated. It generally consists of three parts: the ignition layer, the ignition layer and the coal body. The ignition layer is often mixed with oxidant or paraffin with flammable substances such as carbon and semi-coke powder. The ignition point of the transition layer is slightly higher than the ignition layer and acts as an igniting fire.

Therefore, the calorific value of the raw coal is required to be greater than 6000 kcal/kg and has a suitable particle size. The coal body can adopt anthracite, bituminous coal, lignite, peat or flotation tail. When briquettes made of bituminous coal is burned, the volatile matter and the free carbon produced by pyrolysis are not fully combusted and smoke. Therefore, the volatile matter of the ingredients must be controlled within the range of 20 to 25%, and add an appropriate amount of coke and lime. The inside of coal briquettes has a good microporous structure, which creates a good condition for uniform precipitation of combustible gas.

Desulfurization briquette machine can press the desulfurized gypsum powder for one time, and its capacity is large. The desulfurization gypsum hydraulic briquette machine can press the desulfurized gypsum powder into a ball at a time without adding any binder, and the ball formation rate is above 97%. The pressed ball has a strong hardness, and the loading and unloading should not be broken.

Coal briquettes

China Fote’s coal briquette machine is pressed into a ball at one time without subsequent drying process. Without adding any binder, the purity is guaranteed, which is more conducive to the connection and transformation of the existing process, and the advantages are obvious. FTM Machinery is a professional briquette machine manufacturer. The price of briquette machine is cheap, and many foreign customers had come to our company for a visit and ordered. Excellent product quality and efficient production efficiency have been well received by customers. If you have any questions about the briquette machine, welcome to leave message on our website. FTM company will be happy to help you.

Latest blog

By:ADMINAugust 19,2024

By:ADMINAugust 19,2024

By:AshleyMarch 20,2020

By:AshleyMarch 20,2020

By:AshleyMarch 14,2020

By:AshleyMarch 14,2020

By:AshleyDecember 28,2019

By:AshleyDecember 28,2019

Contact

E-mail:vip@sinoftm.com

Address: No.168 Wutong Street, High-Tech Industrial Development Zone of Zhengzhou City, China.

Hot Products

Future Prospect

We would like to cooperate with customers all around the world, and welcome you sincerely !

Inquiry Online 7×24 Online