By: Zoey April 18,2019 November 11,2024

Granite is an acidic intrusive rock, one of the most common rocks, mostly light red, light gray, gray white, etc. this kind of aggregate structure differs a lot like medium coarse grain, fine grain, and block structure.

Classification of granite

The main minerals are quartz, potassium feldspar and acid plagioclase, and the minor minerals are biotite, hornblende, and sometimes a small amount of pyroxene. There are many kinds of secondary minerals, such as magnetite, vermiculite, zircon, apatite, tourmaline, fluorite and so on.

It contains quartz, potassium feldspar and acid plagioclase, and minor minerals are biotite, hornblende, and sometimes a small amount of pyroxene. Its common secondary minerals are magnetite, vermiculite, zircon, apatite, tourmaline, fluorite and so on.

What is the most important ore of granite? Quartz content is the most abundant in various magmatic rocks, whose content can range from 20-50%, a few can reach 50-60%. Thus, many people also called the granite as the granite ore quartz. The content of potassium feldspar is generally more than that of plagioclase. The ratio of the content of the two is often two-thirds of the total feldspar of potassium feldspar, one third of feldspar, and more potassium feldspar in granite.

It is light red and gray, gray and white. Gray-white potassium feldspar and plagioclase are often difficult to distinguish. At this time, we must carefully observe the twin crystal characteristics of the two feldspars, because the plagioclase has a polycrystalline twin crystal, and when the hand specimen is rotated, there are regular bright and dark patches on the plagioclase crystal, and potassium feldspar. It is a card type twin crystal, which is expressed as two crystal halves with different brightness.

For example, those dark minerals that are mainly biotite are called biotite granitelike. If the dark minerals are mainly amphibole, it can be called two-mica granite.

Granite formation

Granite is a tectonic rock formed by volcanic eruptions and lava that rises to the surface of the crust in a molten state under considerable pressure. The magma does not spurt out of the ground, but it is slowly cooled and solidified under the ground. Acidic igneous rock, belonging to magmatic rock, is also called igneous rock.

The unique physical characteristics of granite and its beautiful patterns make it a good material for architecture, known as the “king of rock”. In the field of construction, it is used to produce concrete and then applied to make roof or floor. If it is crushed, it can be made into cement or be rocked to fill the dam. The granite can save items. The People’s Heroes and the plaques of the Chiang Kai-shek Memorial Hall are both made of granite, which can be preserved for a long time.

Gold quartz granite ore can be widely used in mining, smelting, water conservancy and hydro-power, building materials, roads, railways, crushing and milling, chemical industry and many other departments. Granite is a kind of deep rock, so it’s not easy to be weathered. Its color is beautiful, and the appearance color can be kept for more than 100 years. Due to its high hardness and abrasive resistance, it is considered as the first choice for high-end architectural decoration project, hall floors, and open-air carving.

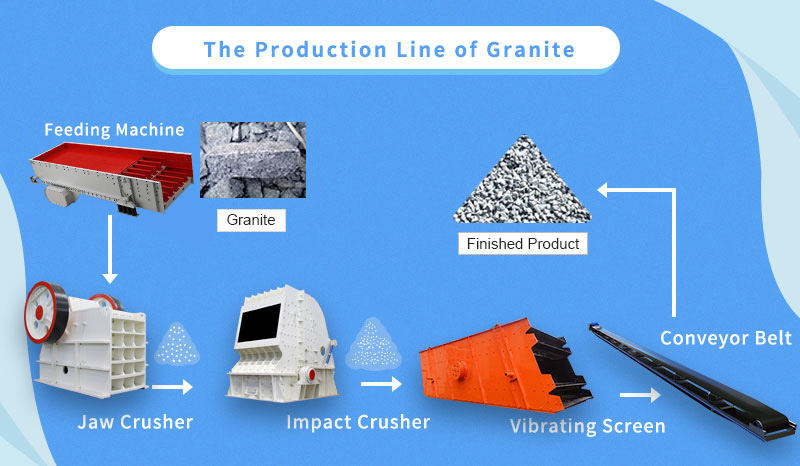

The production line of granite

Firstly, the granite is evenly sent to be roughly broken by the jaw crusher through the vibrating feeder for roughly broken. Secondly, send it to the impact crusher for secondary crushing. If you want small particles such as stones, you can configure the number of layers of the shaker according to the size of the stones you need. If you need two kinds of finished stones, you can configure two layers of vibrating screen. If you want to make sand, you need to crush the stone further. You can get 0-5mm sand through the sand maker and crusher. After cleaning the mud and some impurities in the sand through a sand washer, you can get clean sand.

The granite crushed by the crusher has the characteristic of small particle size and less pulverization. The impact crusher uses kinetic energy to break the material. The kinetic energy of each material is proportional to the mass of the material. Therefore, in the process of crushing, large materials are broken to a large extent, while the small particle materials are not broken under certain conditions.

Granite crushing production line has high degree of automation, large crushing ratio, high production efficiency and large processing capacity. The broken product is in the shape of a cube with low needle-like content, no internal cracks and high compressive strength.

It is easy to maintain the equipment. The wearing parts are made of the latest high-strength wear-resistant materials, which has the advantage of small loss and long service life. It can bring considerable economic benefits to customers.The equipment configuration of the production line is mainly determined by the customer’s requirements on the specification, capacity and usage of the stone.

We will configure the process according to customer’s production site, and strive to provide them with the most reasonable and economical production line.

Due to the reasonable matching of crushing equipment at all levels and the rigorous layout, the stone production line designed by our factory has the characteristics of small footprint, high investment economic benefit, good quality of crushed stone and low output rate of stone powder. At the same time, it is equipped with advanced electronic control operating system to ensure the smooth discharge of the whole process, reliable operation, convenient operation and high efficiency.

HGM German high efficiency raymond grinding mill

HGM German raymond grinding mill with high efficiency, is a new type of product with the international advanced technology. This machine can be used to process all kinds of stone like granite, limestone, quartz, calcite and so on. If you use it, the fineness of finished products can be adjusted between 0.18mm-0.010-mm(80mech-1250mesh), the machine can produce coarse powders ranging from 30 to 80 meshes, used for the highly fine power processing of 280 kinds of non-flammable and non-explosive stuff with Moh’S hardness below 9.3 and humdity less than 6%. So this raymond grinding mill could be the best solution.

Grinding mill machine is mainly used to grind the non-metallic minerals. Its largest capacity can reach 800 meshes, so the finished material is very fine. However, compared with the ball mill, the raymond grinding mill’s capacity is small. Therefore, if you want to grind the material with large capacity, we can also provide you with the high-quality ball mill grinder.

We can guarantee that the grinding mill parts have long service life. Generally, you can use the machine for 3-5 years. If there are any problems about the mineral grinding mill, we can also offer you the supplementary parts.

Henan Fote company allow you to carry your material for a test on the machine before ordering. If you are interested in our equipments, please leave your message on our message board, and our technology manager will make a professional plan for you. In addition, you can also come to our company for a visit. Welcome to FTM Machinery!

Tags:Mining, Minerals, Grinding mill machine, Granite, Aggregates

Latest blog

By:ADMINAugust 19,2024

By:ADMINAugust 19,2024

By:AshleyMarch 20,2020

By:AshleyMarch 20,2020

By:AshleyMarch 14,2020

By:AshleyMarch 14,2020

By:AshleyDecember 28,2019

By:AshleyDecember 28,2019

Contact

E-mail:vip@sinoftm.com

Address: No.168 Wutong Street, High-Tech Industrial Development Zone of Zhengzhou City, China.

Hot Products

Future Prospect

We would like to cooperate with customers all around the world, and welcome you sincerely !

Inquiry Online 7×24 Online