By: Ashley November 15,2019 November 11,2024

The international market shows a gradual decrease in demand for low-grade magnesite and the increase for high-grade magnesite. The price of 20-100mm magnesite ore is about 30 USD/ton, while the price of magnesite powder after beneficiation is about 85-145 USD/ton. Therefore, it is a general trend to invest in magnesite beneficiation. In order to remove harmful impurities from magnesite and improve its grade, it’s necessary to carry out purification. Flotation is the most common, simplest, and most frequently used method. The high-purity magnesite powder produced by the flotation process is widely used with remarkable economic benefits in the industries such as military, aerospace, steelmaking, chemical and non-ferrous metal casting, etc.

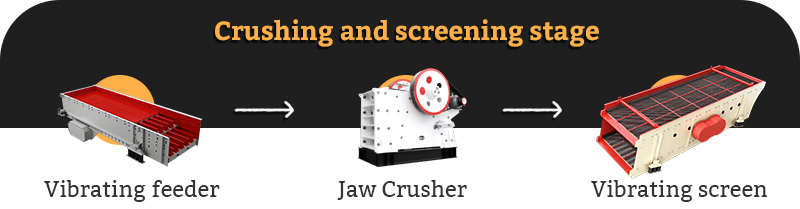

Crushing and screening stage: Vibrating Feeder, Jaw Crusher, Vibrating Screen

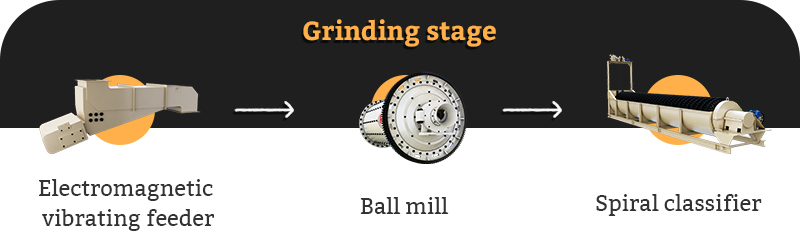

Grinding and grading stage: Electric-magnetic Vibrating Feeder, Ball Mill, Spiral Classifier

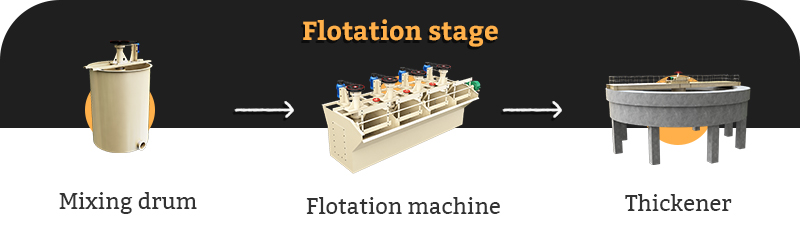

Flotation stage: Mixer, Flotation machine, Concentrator

Drying stage: Filter, Dryer

Sodium Hexametaphosphate, Sodium Silicate, BK-428, BK 410B, Sodium Hydroxide

The equipments used in this stage are the vibrating feeder, jaw crusher and vibrating screen. Firstly, send the magnesite ores with particle sizes less than 200mm through vibration feeder to the jaw crusher for crushing, and then screen them by vibrating screen. If you find any ores with particle sizes larger than 10mm, which does not meet the grinding requirements, send them back to the crusher again until they are crushed to 0-10mm.

crushing and screening stage

Grinding and grading stage is very important for flotation process. Grinding fineness is an important factor affecting the separation index and appropriate grinding can effectively dissociate target minerals and gangue minerals. Put the crushed ore with size less than 10mm into the ball mill for monomer dissociation. Usually, two-stage grinding or three-stage grinding is used. The requirements of the final product is that 0.074mm ores account for more than 70%, which can achieve the best grinding fineness.

griding stage

The beneficiation equipments mainly used in the flotation process of the magnesium ore are the flotation machine, mixer and concentrator. Because the use of a single reverse flotation process cannot effectively remove impurities from the ore, the magnesium flotation process is generally composed of reverse flotation and direct flotation. Reverse flotation is used to select all tailings and direct flotation is to obtain magnesium concentrates and middlings. Send the magnesite powder grinded by the ball mill to the mixer to mix the powder with flotation agents. Then use reverse-direct flotation technic and finally send it to the concentrator to form flocs in the pulp to reduce its moisture content.

flotation stage

The flotation process is as follows:

·Put the graded magnesite into the flotation machine and adjust the pulp to be acidulous with ph of 6.0 for reverse flotation. Add 650 g/t of sodium silicate inhibitor and BK-428 150 g/t as a collecting agent.

·After rougher flotation, add BK-428 70 g/t and 50 g /t respectively for concentration.

·Then, carry out direct flotation. Adjust the pulp by sodium hydroxide to be alkalescent with ph of 9.3 and add 300 g/t of sodium hexametaphosphate inhibitor and 1 500 g/t of BK410B collector.

·After rough flotation, carry out concentration for three times. Add sodium hexametaphosphate 50g/t and BK410B 200 g/t as well as sodium hexametaphosphate 25g/t and BK410B 100 g/t respectively in the first two times. The third time you add nothing and you get magnesite concentrate.

Magnesite concentrate with 46.60% of MgO and recovery rate of 77.78% can be obtained from low-grade magnesite ore with 42.90% of MgO.

(Data from Conservation and Utilization of Mineral Resources)

Drying is the last step in the production of finished products and the filter and dryer are used in this stage. The magnesite powder after flotation has a large water content, which is reduced after concentration, but it cannot be used in industry directly. Therefore, the dryer is used to completely dry the magnesite powder.

drying stage

| Reagent | Dosage (g/t) | Unite Price (USD/t) | Amount (USD) |

| Sodium Hexametaphosphate | 375 | 1069 | 0.4 |

| Sodium Silicate | 650 | 143 | 0.09 |

| BK-428 | 270 | 3276 | 0.09 |

| BK410B | 1800 | 1425 | 2.57 |

| Sodium Hydroxide | 180 | 428 | 0.08 |

| Total | 3.23 | ||

| Machine | Price (USD) |

| Vibrating Feeder | 1,500-70,000 |

| Jaw Crusher | 15,000-850,000 |

| Vibrating Screen | 7,000-11,000 |

| Electric-magnetic Vibrating Feeder | 7,500-18,000 |

| Spiral Classifier | 5,000-10,000 |

| Mixing Bucket | 3,000-60,000 |

| Flotation Machine | 10,000-150,000 |

| Concentrator | 2,000-15,000 |

| Filter | 20,000-10,000 |

| Dryer | 20,000-150,000 |

| Total | 99,000-2,344,000 |

As can be seen from the above table, the price of ore beneficiation equipments on the market varies widely and makes people dazzling. If you want to avoid this kind of trouble, you can choose our company to customize the beneficiation production line for you according to your actual needs. Our company has a full range of mineral processing equipment with high quality, excellent performance and popular price. From the configuration of the production line, the selection of equipment, to the transportation, installation and operation of the equipment, we provide you with comprehensive services. If you want to know more about our company and our equipments, please leave your information on the right form and we also welcome you to come to our company for on-the-spot visits at any time. We will be dedicated to your service!

Latest blog

By:ADMINAugust 19,2024

By:ADMINAugust 19,2024

By:AshleyMarch 20,2020

By:AshleyMarch 20,2020

By:AshleyMarch 14,2020

By:AshleyMarch 14,2020

By:AshleyDecember 28,2019

By:AshleyDecember 28,2019

Contact

E-mail:vip@sinoftm.com

Address: No.168 Wutong Street, High-Tech Industrial Development Zone of Zhengzhou City, China.

Hot Products

Future Prospect

We would like to cooperate with customers all around the world, and welcome you sincerely !

Inquiry Online 7×24 Online