Welcome to the photo gallery of our products, then you will find the lightspot of various equipment, and enjoy yourself !

The two-stage crusher is composed of box, rotor, hammer, counter lining, sieve plate. Based on the traditional small hammer crusher, the double stage crusher or the two-stage crusher has been improved a lot, so it is also called double rotor hammer crusher.

It has two sets of rotors, and can totally crush rock materials twice. The effect of single two-stage crusher is equal to two common crushers.

Two-stage crusher

The material crushed by the upper rotor is immediately shredded again by the lower rotor that is rotating at high speed. The materials impact with each other and become powder in the cavity.

The traditional pulverizer with enamel sieve is not suitable for raw materials with moisture content more than 8%.

When the moisture content of raw material is higher than 10%, it is prone to severe blockage, so that the hammer can not rotate, the material cannot be discharged, even the motor is burned, which seriously affects the production.

The double-stage crusher doesn’t have screen bottom, and there is no strict requirement on the moisture content of the material. It doesn’t block the sieve plate at all, and the fine powder can be discharged in time.

Fote heavy machinery company uses the high alloy material to manufacturer the wear-resistant hammer. Hammerhead combines the hammer handle to operate the machine.

It doesn’t matter that the hammer and liner of two-stage crusher are worn out. As long as the position of the hammer is changed, it can be used repeatedly. A pair of hammers can be used as three pairs.

Only one person can start up and shut down the crusher, which is not only light, fast, but safe and reliable. Furthermore, it’s easy to maintain.

The two-stage crusher is able to break materials including limestone, bricks and tiles, coal cinder, furnace cinder, slag, gangue and construction waste, etc.

In order to avoid blocking, double-stage crusher does not install the grid and screen, which solved the problem of high temperature and high humidity in the process of crushing. The twin-stage crusher equals two hammer crushers working together.

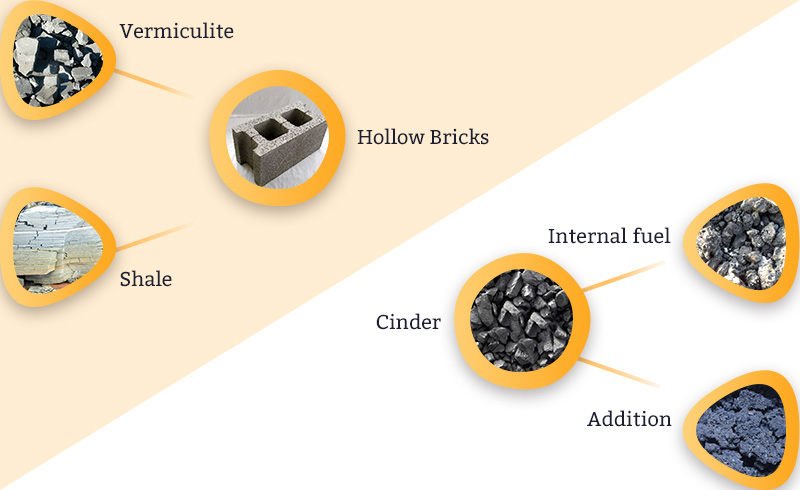

The reasonable combination realizes the series application of two sets of rotors. Vermiculite and cinder can be used as brick plant additives and internal fuel, while shale and vermiculite can produce standard and hollow bricks.

Application of two-stage crusher

When it works, the twin-stage crusher’s two rotors revolve at the same time at high speed driven by the double electric motors.

Materials in the crushing cavity are immediately crushed by the lower rotor’s hammerhead with high-speed rotation after first being crushed by the high-level rotor.

Materials are completely impacted with each other and crushed into the coal cinder powder with the discharging size less than 3mm.

Working principle

Henan Fote Heavy Mining Machinery is the professional mining manufacturer. We have exported many types of equipment to India, Indonesia, South Africa, Brazil, etc. We have three large production bases covering an area of 350,000 square meters. And the two-stage crusher factory is the main production base. We have the after-service team that can offer you the installment guidance, technology training, and shipping. If you want to know more, please leave a message on our message board and we will send you the latest price.

| Specifition | Capacity (t/h) |

Motor Power (kw) |

| 2PC 600×600 | 10-30 | 22+22 |

| 2PC 800×600 | 18-55 | 45+55 |

| 2PC 1000×800 | 22-90 | 55+75 |

| 2PC 1200×1000 | 30-120 | 90+110 |

| 2PC 1400×1200 | 40-140 | 132+160 |

| 2PC 1600×1400 | 50-180 | 160+200 |

| 2PC 2000×1600 | 60-300 | 400+400 |

| Specifition | Capacity (t/h) |

Motor Power (kw) |

| 2PC 600×600 | 10-30 | 22+22 |

| 2PC 800×600 | 18-55 | 45+55 |

| 2PC 1000×800 | 22-90 | 55+75 |

| 2PC 1200×1000 | 30-120 | 90+110 |

| 2PC 1400×1200 | 40-140 | 132+160 |

| 2PC 1600×1400 | 50-180 | 160+200 |

| 2PC 2000×1600 | 60-300 | 400+400 |

| Specifition | Capacity (t/h) |

Motor Power (kw) |

| 2PC 600×600 | 10-30 | 22+22 |

| 2PC 800×600 | 18-55 | 45+55 |

| 2PC 1000×800 | 22-90 | 55+75 |

| 2PC 1200×1000 | 30-120 | 90+110 |

| 2PC 1400×1200 | 40-140 | 132+160 |

| 2PC 1600×1400 | 50-180 | 160+200 |

| 2PC 2000×1600 | 60-300 | 400+400 |

Contact

E-mail:vip@sinoftm.com

Address: No.168 Wutong Street, High-Tech Industrial Development Zone of Zhengzhou City, China.

Hot Products

Future Prospect

We would like to cooperate with customers all around the world, and welcome you sincerely !

Inquiry Online 7×24 Online