Welcome to the photo gallery of our products, then you will find the lightspot of various equipment, and enjoy yourself !

Sawdust dryer

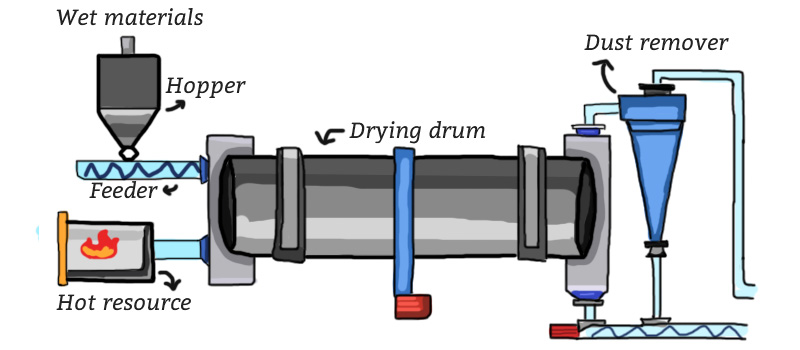

This is a kinld of airflow sawdust dryers. The powdery wet sawdust is continuously added to the drying tube by a screw conveyor. During the transportation and dispersion of the high-speed hot gas stream, the water in the wet material is evaporated to obtain the powdery or granular drying product.

The sawdust dryer is mainly applied in drying materials with a certain humidity or particle size in the departments of mineral processing, building materials, metallurgy, and chemical industry. The dryer has strong adaptability to materials and can dry various materials. Because the equipment operation is simple and reliable, so it is widely used among customers.

The cylinder of the FTM sawdust dryer is mainly composed of a rotating body, a lifting plate, a transmission device, a supporting device, and a sealing ring.

Sawdust dryer is specially designed for drying wood chips, sawdust, wood powder, wood chips and other materials. It has the characteristics of large drying output, remarkable energy-saving effect and low maintenance. It is suitable for straw briquette fuel, charcoal machinery, wood pellet fuel, sawdust briquette, agriculture and animal husbandry engineering and other industries. Fote Machinery, as the sawdust dryer manufacturer, possesses the high-end production technology. We not only have the large sawdust dryer but also have the small sawdust dryer. They are both for sale. If you want to know more, please leave a message on our website.

The sawdust dryer of FTM machinery adopts an automatic control system of temperature, which is full of energy-saving, durability, and large throughput.

Production capacity: 1.9-76.0t/h

Cylinder volume: 9.0-285m3

Total weight: 9-135t

Applicable materials: river sand, copper ore, hematite, limonite, molybdenum ore, gold ore, iron ore, limestone, clay, etc.

The sawdust dryer

General dryers typically use coal or wood as the heat source, which requires high density and high cost. In addition, the thermal efficiency loss is large, so that the heat utilization rate of the sawdust dryer is less than 30%. Typically, materials with a water content of 35% should be dried 3-4 times.

However, the sawdust dryer can successfully dry materials with a water content of 35% at a time, saving 75%, greatly reducing the cost. The gas from the sawdust dryer comes from a coke oven where methane gas is produced.

FTM sawdust dryer can process new kinds of biomass fuel and realize the secondary utilization of resources. It can also greatly increase the rate of burning and greatly reduce the pollution on the environment.

The sawdust dryer can make fodder of flowers and trees. And it can also make compression plate.

The sawdust dryer can be applied to aquaculture production. The sawdust that has been dried by the saw dust dryer can be used in the breeding production to make the chicken and duck pigsty clean.

The energy-saving airflow sawdust dryer will firstly dry the sawdust and then crush them together with other materials, whose aim is to make the semi-finished raw material for mechanical carbon. FTM sawdust dryer is an ideal production with less investment and quick effect.

The sawdust dryer of FTM heavy machinery adopts a new type of lifting plate device, which has many functions such as guiding, current sharing and lifting. It can make the material uniformly distributed, and the material is in the radial section of the dryer.

Besides, the material curtain can appear thin, uniform and full. The sawdust dryer system has good sealing performance, it is equipped with a complete dust removal device. If the dust is small and the operating environment will be good. The LX multi-assemblage lifting plate is used to increase the contact surface between the material and the hot air, and contact the hot air flow to achieve the purpose of fully utilizing the heat energy.

The sawdust dryer uses reasonable parameters. The coal and electricity consumption of sawdust dryer are reduced by 10-15% for dryers and 10-15% for production than general ones. It has been widely used in cement and mineral processing enterprises.

The working principle of sawdust dryer

The heat source of the industrial dryer comes from the combustion device, and the industrial dryer adopts the downstream heating method. Therefore, the dried material is slid into the cylinder from the feed, and then the material is pushed to the rear end by the spiral copy board. As the dryer inclines against the ground, the material flows to the rear end under the effect of gravity and rotation.

On the other hand, the material is repeatedly picked up by the copying board firstly, and then it is taken to the upper end, finally, the material is continuously sown down, so that the material forms a uniform curtain in the cylinder. The curtain is fully exchanged with the hot air flow in the cylinder. As the material is repeatedly spread, the moisture contained is gradually dried, thereby achieving the purpose of drying.

The heat source of the sawdust dryer is mainly composed of the combustion products, such as air, water vapor, hot water, electric energy, etc. At the same time, the selection of the heat source also affects the operating cost of the sawdust dryer. When choosing the heat source of the sawdust dryer, it is necessary to choose from the suitable heat source, like the local conditions, the safety of the heat source, the environmental requirement, and the quality of the dried material.

The Zhengzhou Fote machinery’s sawdust dryer for sale. If you have any mining project, you can leave your message on our website. Fote company is the professional mining manufacturer with three large production factories. We also have after-service team to help you solve the problem of installment, guidance, and training.

Contact

E-mail:vip@sinoftm.com

Address: No.168 Wutong Street, High-Tech Industrial Development Zone of Zhengzhou City, China.

Hot Products

Future Prospect

We would like to cooperate with customers all around the world, and welcome you sincerely !

Inquiry Online 7×24 Online