Flotation seperation plant is used to separate non-ferrous black metal like copper, zinc, lead and gold) and suitable for coarse separation and fine separation for nonmetal like fluorite and talc.

The flotation process is suitable for the treatment of gold-bearing sulfide ore with fine gold particles and good floatability. During the flotation process, the sulfide ore is enriched as a gold carrier in the sulfide concentrate, and the flotation method is also available to deal with polymetallic gold-bearing sulfide ore and carbonaceous ore. In addition, for “difficult ore” that cannot be directly treated by amalgamation or cyanidation, it is also necessary to use a combined process including flotation.

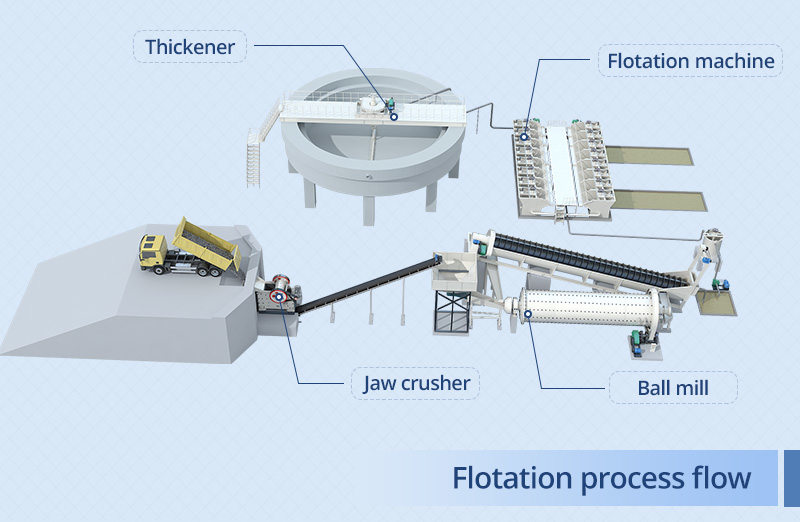

Flotation plant or flotation line is mainly composed of jaw crusher, ball mill, spiral classifier, agitation barrel, and flotation machine.

| Equipment | Function |

| Jaw Crusher | Crush the material to below 300 mm for the first-stage crushing |

| Ball Mill | Crush and grind materials of 20 mm to 0.074–0.4 mm |

| Spiral classifier | According to the different specific gravity of the materials, the ore mixture is washed and classified |

| Magnetic separator | Magnetic material is separated from other materials by magnetic and mechanical forces |

| Flotation machine | Add reagents to separate the required minerals from other substances |

In the flotation separation process or flotation processing line, the pulp after processed by adding in agentia makes air inflation by mixing to make some ore particle stick to the bubble. Float to the surface of the pulp and being scraped to make bubble product and the rest are in the pulp to achieve separation. Flotation machines are in various types and the most common type is mechanical mixing flotation machine.

Firstly, carry out the graphite ore dressing test. The test samples were taken by the client and sent to our company. After the samples were tested, the raw ore was grinded in nine stages, followed by one roughing, one scavenging and nine concentrations. The graphite concentrates with a yield of 14.20%, a fixed carbon content of 92.30% and a recovery rate of 87.91% could be obtained.

An iron ore mine in the Philippines contains 0.15% copper, 5.59% sulfur, and 43.47% iron. It belongs to the refractory polymetallic ore because the relationship between sulfur and iron is very close and the disseminated grain size is quite fine. the technological scheme of "stage grinding - stage low intensity magnetic separation - obtaining iron coarse concentrate - flotation desulfurization of the coarse iron concentrate" is adopted.

Contact

E-mail:vip@sinoftm.com

Address: Tanxiang Road, High-Tech Industrial Development Zone of Zhengzhou City, P. R. China.

Hot Products

Leave your personal information(Only kept by FTM), for sending a favorable price meets your production budget.

Inquiry Online 7×24 Online