By: Ashley August 28, 2019 Last Updated :November 30, 2019

As we all know that with the continuous exploitation of mineral resources, mineral resources are constantly decreasing. In the process of mining, many ores are wasted and not fully exploited, which is very unfavorable for the protection of resources. Therefore, the full utilization and processing of mineral resources are very important. In the process of disposing and utilizing ore resources, the application of crusher equipment is inseparable. Only when the natural ore is processed through the crusher equipment to obtain the required particle size in the market, more resources can be said to be fully utilized. Therefore, stone crushing equipment can be said to be indispensable equipment for ore resource processing, and it plays a very important role in the ore market.

It can meet the processing needs of different stone materials and is an indispensable device in ore processing operations. With the continuous innovation and development of science and technology, the technical processes of this crusher equipment have also been greatly improved to better meet the needs of the market. As a crusher equipment manufacturer, Henan Fote Heavy Machinery Co., Ltd. has continuously carried out technological innovations and upgrades on crusher equipment and has achieved great breakthroughs in crusher equipment technology, and at the same time realized the optimization and upgrading of equipment structure and performance.

The states of mining resource

FTM Machinery has also launched a series of high-performance equipment, such as PE jaw crusher, PEX jaw crusher, CJ jaw crusher, HD jaw crusher, single cylinder hydraulic cone rock crusher, a new type of tertiary crusher, impact crusher, etc. These high-performance equipment have great advantages in both technology and structure, and the effect of ore crushing is outstanding.

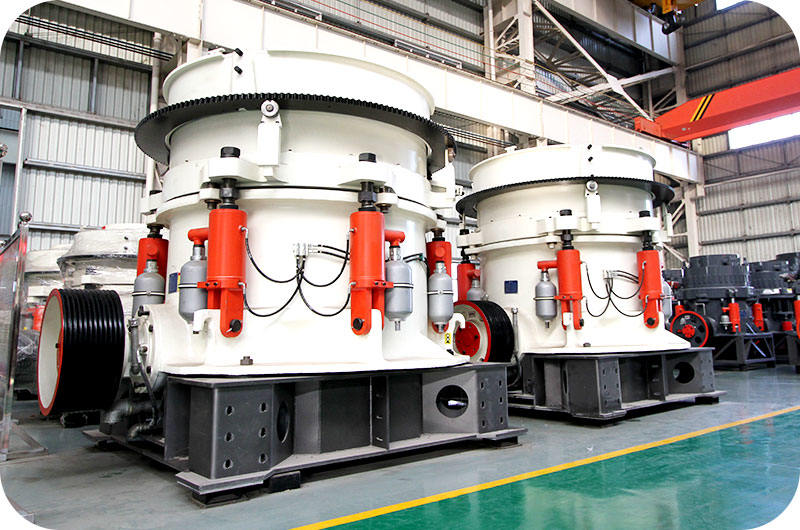

Cone crushing machine is applied to the fields of mining crushing, metallurgical, chemical, construction, construction waste recycling, cement and gravel production. The cone crushing machine has high crushing efficiency, low maintenance cost, fully automatic control of the production process, and can adapt to different production process requirements. It has become the mainstream crushing equipment in the mining industry. Single cylinder hydraulic cone rock crusher is one of the cone crusher plants with the advantages of simple and compact structure, low failure rate and high reliability.

SC315S single cylinder hydraulic cone crushing machine integrates mechanical, hydraulic and intelligent control technologies. The new crusher structure, optimized laminated crushing chamber type, and all-intelligent automatic control system make the SC315S series single-cylinder hydraulic cone crushing machine have the unparalleled performance characteristics compared with the traditional cone crusher plant. A variety of optional cavity shape, high crushing efficiency, low production cost, convenient adjustment and maintenance, excellent product size, and these advantages of China cone crushing machine can be widely used in medium, fine and ultra-fine operations. Its maximum feed size is 500mm, minimum discharge size is 38mm, installed power is 315kw, and the processing capacity is 318-892t/h.

Cone rock crusher for sale

Cone crushing machine has become the development direction of crusher because of its simple structure, light-body, high output, relatively stable work, and easy automatic control. The cone crusher plant crushes hardness or medium hardness material, and its compression ratio is large, the output and quality are better, and the product has a uniform particle size and consumes less energy.

There is also a disadvantage about the cone crusher plant, that is, the finished needle-like product is much, and the granular shape is not good enough. But after 1980, some scholars proposed the theory of lamination crushing. Then, what is the lamination crushing? What requirements do you need to achieve laminate fracture?

The process of making the material be squeezed, ground, and broken at its cracks and defects is called laminating fracture. Under normal circumstances, in the on-site operation of the cone crusher plant, only when the size of the material is large, or the size of the crushing cavity is small enough to form an effective fracture layer, it can be considered that single-particle breakage has occurred, which means that only the material at the inlet and outlet will undergo single particle breakage. Generally, much material will be crushed in this case, that is, the material is laminated and fractured at other positions in the crushing chamber.

The theory of laminar fracture refers to the crushing of materials in a multi-layered distribution in the crushing chamber. When the material is broken, it will not only be subjected to the pressing force of moving cone and the fixed cone but also the extrusion collision between materials, which a true reflection of the broken state of the material in the crushing chamber.

Certain prerequisites must be satisfied to enable the material to achieve the effect of lamination crushing.

(1) Enough raw material. Only a sufficient amount of material will form a certain layer of material, the fracturing effect will be achieved. When the number of broken layers is 6-10, the energy-saving effect will be obvious, and the advantage of high fracture yield will be reflected.

(2)Uniform feeding. Uniform feeding will make the material force distribution reasonable so that the crusher works smoothly.

(3)Uniform particle size. When the material sizes vary, small materials will protect large materials from being broken, and this is fine particle protection. Therefore, to avoid this phenomenon, the particle size of the feeding should be uniform.

(4)Filling rate. When the material filling rate is too small, powdery particles will appear, which will cause waste, thereby reducing the effect of laminating fracture; When the filling rate is too large, the material is too tight and easy to hold the group, which is not conducive to the crushing. A series of tests have shown that the filling rate between 0.55 and 0.75 is the most choice for the lamination of the laminate.

This customer is a large integrated joint-stock enterprise, possessing several mining projects like granite mine, gypsum mine, and iron ore. In the face of increasingly fierce market competition, to develop advantages of the industrial chain, it is planned to build a high-quality sand and gravel aggregate production line to enhance the efficiency of enterprises. After many customers’ inspection and communication, Henan Fote Heavy Mining Machinery wons the trust of customers with excellent project plan and product technology and finally reached this cooperation.

Raw material: granite

Size of raw material: 200-1200mm

Finished products: Fine sandstone aggregate

Finished product specification: 0-20mm;20-31.5mm

Capacity: 600-700T/H

Cone crushing machinery production site

This project adopts domestic mature process and reliable technology and equipment, ensuring the whole production technology and process equipment are at the domestic advanced level. China Fote made a plan of tertiary crusher and sand making machine. The centralized layout of the production line not only saves the floor space but also facilitates the inspection and maintenance of equipment.

The use of mine tailings for production, effectively reducing raw materials, low cost and improved economic benefits. On this basis, utilizing the original drop of the mine for the production line design not only saves the belt machine usage but also reduces the customer’s operating costs.

The project is equipped with dust-removing standard factory buildings, and the equipment is produced in a fully sealed environment, which effectively reduces environmental pollution and meets the national high standards of environmental protection.

The core equipment and solutions are designed and provided by a professional team. The equipment has high quality and the process flow is smooth. In today’s market environment, the production line is put into production, not only can meet the high standards of customers, but also bring considerable investment income to customers.

In this project, Fote company always adheres to the service concept of “quick response and efficient communication”, strictly grasps all aspects of the project construction stage, ensures that the project can be carried out safely and orderly, efficiently and quickly. FTM Machinery will take this as a deed, continuously innovate, and strive to provide customers with more efficient, environmentally friendly and comprehensive project services in future development.

China FTM cone crusher plant

Latest blog

By:AshleyMarch 20, 2020

By:AshleyMarch 20, 2020

By:AshleyMarch 14, 2020

By:AshleyMarch 14, 2020

By:AshleyDecember 28, 2019

By:AshleyDecember 28, 2019

By:AshleyDecember 20, 2019

By:AshleyDecember 20, 2019

Contact

E-mail:vip@sinoftm.com

Address: No.168 Wutong Street, High-Tech Industrial Development Zone of Zhengzhou City, China.

Hot Products

Future Prospect

We would like to cooperate with customers all around the world, and welcome you sincerely !

Inquiry Online 7×24 Online