By: Ashley August 30,2019 November 11,2024

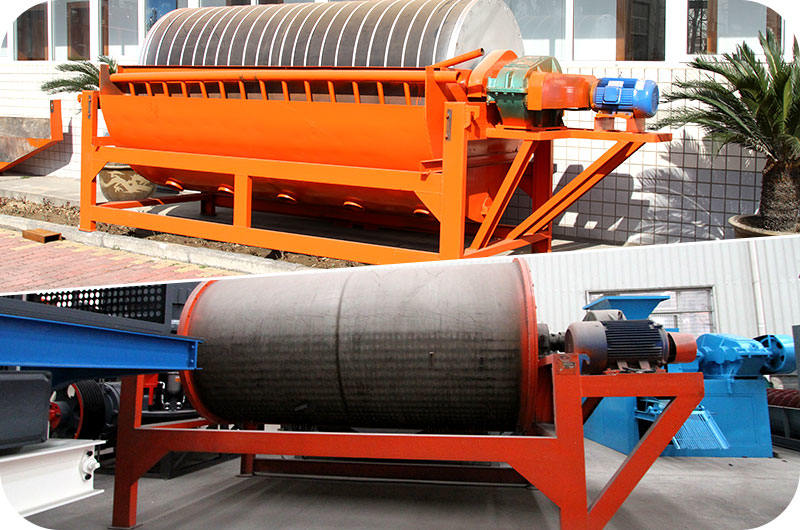

The magnetic separator machine is one of the most widely in resource recovery, timber industry, mining, kiln, chemistry, and other workshops. In the magnetic separation process, different minerals must be graded, which is also prepared for better magnetic separation. We have to carry out the monomer dissociation degree on the ground ore, which can separate the minerals smoothly. The selection index depends to a large extent on the operation of grinding operation.

If the fineness of the ground product is not standard, the minerals do not reach sufficient monomer separation, so the selection of indicators will not be good. Besides, if the ground mineral is too fine, too many particles will be produced, which will also reduce the beneficiation index. Therefore, to obtain a suitable particle size, it depends not only on the beneficiation method but also on material requirements of the magnetic separator machine.

The slurry concentration is one of the main factors affecting the magnetic separation effect. It mainly refers to the overflow concentration of the magnetic classifier. If the concentration of slurry is too large, resulting in too high a sorting concentration, the quality of the concentrate will be seriously affected. If the ore particle size is small, it indicates that the mineral monomer has a high separation degree and can obtain a satisfactory selection index.

Concentrate particles are easily separated by finer gangue particles and are selected together to lower grade. If the concentration of the slurry is too small, the flow rate will increase, and the separation will be shortened, so that some small magnetic particles that would have been brought up in the tailings will fall into the tailings, causing tailings to increase in grade. Therefore, the pulp concentration should be adjusted as needs. The maximum concentration of feed slurry should not exceed 35%, and the control is generally around 30%.

Magnetic separator process

The magnetic separator equipment is widely applied to recycle the resource, and used in industries of the timber industry, mining, kiln, chemistry, food. It is suitable for the wet magnetic separation of magnetite, pyrrhotite, roasting ore, and pyrite lamp materials with a particle size of 3mm or less. It is also used for separating the iron ore from coal, non-metallic minerals, building materials, etc. The new type of magnetic separator manufacturer from FTM Machinery has been fully put into using and has a strong response in the magnetic separation equipment industry.

The magnetic system of magnetic separator is made of high-performance rare earth boron material and high-quality ferrite material. The maximum magnetic induction intensity of the barrel sorting area is above 0.8T, and the magnetic field strength is 3-5 times that of the conventional coal magnetic separator. The magnetic field force of the sorting zone can reach the magnetic level of electromagnetic depolarization machine. The sorting cylinder is made of wear-resistant stainless steel.

The sorting mineral is evenly fed to the upper part of sorting cylinder through the vibrating feeder, and the rotating cylinder throws the non-magnetic material away from the cylinder. Magnetic material is attracted to the cylinder by strong magnetic force. Using the separation board can precisely separate the iron from magnetic or non-magnetic materials.

Henan Fote machinery’s magnetic separating machine can greatly process the material. China Fote‘s magnetic2019-09-12 11:01:40 星期四 separator equipment has a large processing capacity, a wide range of sorting minerals, high separation precision, simple structure, and no blockage. Its power consumption is only 20% of the electromagnetic magnetic separator. Its biggest highlight is the demineralization operation for refractory materials and other materials.

Sand washer machine in India

Although magnetic separator machine is the core equipment of the mining field, many people are still not familiar with it. Here is some knowledge about the magnetic system height, magnetic system width, magnetic system radius, magnetic system pole pitch.

The height of the magnetic system has a certain influence on the average magnetic field strength of the magnetic pole surface. When the cross-sectional area of the magnetic pole group in the magnetic system is constant, the average magnetic field strength of the surface of the magnetic pole group increases as the height of the magnetic pole group increases. When the height of the magnetic pole group is increased to a certain value, the magnitude of the increase in the average magnetic field strength on the surface of the magnetic pole group is reduced. The height of the magnetic system was determined to be 30 mm in combination with the weight of equipment and the case of experimental research.

The magnetic system width of the magnetic separator refers to the length of a magnetic system along the axial direction of the cylinder. When the magnetic system width is increased, the magnetic flux leakage is reduced, and the magnetic field strength at each point above the magnetic pole is increased. The magnetic system with a small width is closer to the edge of the magnetic system and the lower the magnetic field strength is, the larger the drop is. A magnetic system with a large width, the magnetic field is uniform over a wide range.

The magnetic field distribution of a wide magnetic system in the axial direction of the cylinder has the characteristics of low height at both ends of the middle section. This is because magnetic flux is scattered at both ends of the magnetic system. This characteristic and the existence of magnetic flux dispersion should be considered when designing the width of ore feeder and the discharge port of magnetic separator.

The width of the magnetic system determines the width of the ore, which determines the processing capacity of the magnetic separator. Since the equipment is in the experimental stage, the miniaturization is easy to adjust and correct, so the magnetic system width is determined to be 240 mm from the viewpoint of less influence of processing factor.

The magnetic system radius of the magnetic separator China has a great influence on the processing capacity of the magnetic cylinder. As the radius of magnetic system increases, the selection work area is lengthened accordingly, and more magnetic poles can be arranged in the magnetic system, which helps improve the taste and recovery rate of the concentrate.

Increasing the radius of the magnetic system, not only is conducive to the average magnetic field strength, but also the height of the sorting work area is also increased. When the radius of the magnetic system increases within a certain range, the processing capacity of the magnetic separator equipment is significant. When it continues to increase, the increasing amplitude is not obvious.

The magnetic system pole moment is the sum of the pole face width and the pole gap width. The weight of magnetic system is related to the pole distance of magnetic system. The smaller the pole distance, the lighter the weight of the magnetic system is. From this point, it seems that using a small pole magnetic system is reasonable. However, the pole pitch is small, and the strength of magnetic field leaving the surface of pole drops too fast.

When selecting a large ore, some of the ore will be in an area where the magnetic field strength is too low, and the ore will be lost to the non-magnetic product. From this, a qualitative conclusion can be drawn: when the thickness of the core layer is small or the concentration is low, ore particles move close to the surface of magnetic system, and a small pole-distance magnetic system can be used. When the thickness of the core layer is large or the concentration is high, a magnetic system with a large pole pitch can be used.

Therefore, the pole pitch of magnetic system is determined by the particle size of selected ore or the thickness of the ore layer and the distance from the ore layer to the surface of the pole. The suspension magnetic separator machine is mainly used for selecting fine ore, and the large concentration of ore layer will increase the entrainment phenomenon, thereby reducing the sorting precision, so a small pole magnetic system is used. The pole distance value is set to 40 mm.

Dry magnetic separator VS wet drum magnetic separator

Latest blog

By:ADMINAugust 19,2024

By:ADMINAugust 19,2024

By:AshleyMarch 20,2020

By:AshleyMarch 20,2020

By:AshleyMarch 14,2020

By:AshleyMarch 14,2020

By:AshleyDecember 28,2019

By:AshleyDecember 28,2019

Contact

E-mail:vip@sinoftm.com

Address: No.168 Wutong Street, High-Tech Industrial Development Zone of Zhengzhou City, China.

Hot Products

Future Prospect

We would like to cooperate with customers all around the world, and welcome you sincerely !

Inquiry Online 7×24 Online