Welcome to the photo gallery of our products, then you will find the lightspot of various equipment, and enjoy yourself !

The shaking table is a gravity beneficiation equipment for selecting fine materials. When the gold shaking table in action, the effective particle size range of metal ore is 3~O. 019 mm. While it processes the coal, the upper limit granularity is 10mm. The outstanding advantage of the shaker is that the sorting precision is high, and high-grade concentrate or waste tailings can be obtained by one sorting, and multiple products can be taken out at the same time. Besides, the shaking table is easy to adjust.

Mining gold shaking table is a common mineral processing equipment for sorting fine ore. When the metal ore is processed, the effective particle size range is 3~O. 019 mm, the upper limit particle size can be up to 10 mm when coal is selected. The outstanding advantage of 6-S shaker is the high precision of sorting. High-grade concentrate or waste tailings can be obtained by one selection, and multiple products can be taken at the same time. The flat 6-S shaker is easy to handle and easy to adjust. The main disadvantage is that the equipment covers a large area and the processing capacity per unit of the factory area is low.

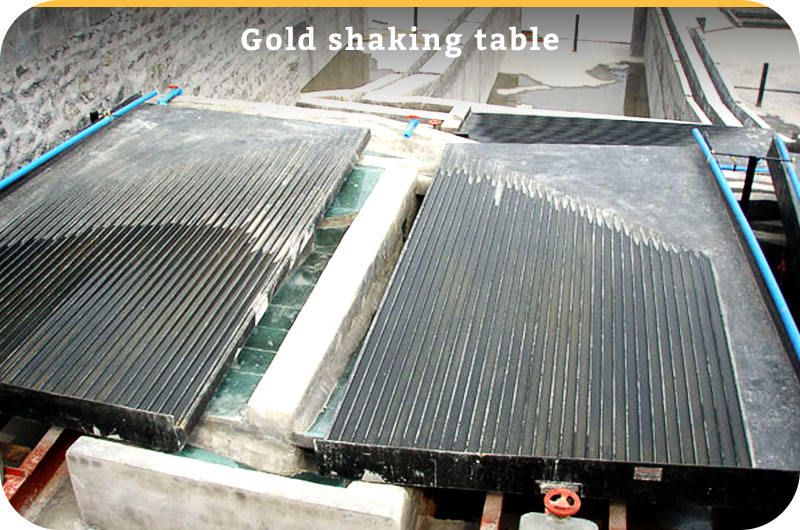

Gold shaking table

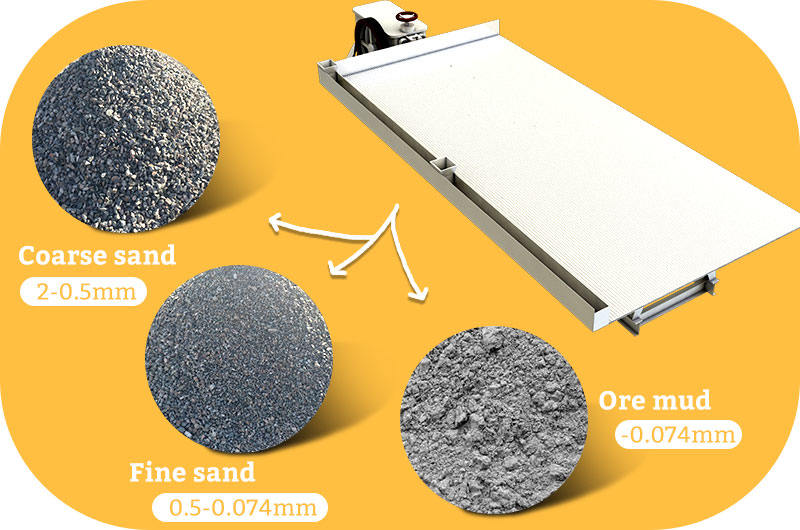

Shaking table is widely used in many industries, and can be used for rough selection and sweeping of materials. Its main materials are various metals and heavy metal materials such as gold, silver, zinc, tungsten, iron, manganese, lead, coal, etc. The size of coarse sand is 2-0.5mm, and the fine sand is 0.5-0.074mm. The effective recycling range of shaking table is 2-0.22mm when processing the tungsten, tin and other metal ore materials.

Applicable materials of shaking table

The gold shaking table is made up of table surface, main frame, transmission device and motor. Moreover, the gold shaking table will be armed with the water filling chute, feeding chute and engine base.

1.The shaking table is easy to be installed, has simple operation. And the gold shaking table cost is low, while its cost-effective is high.

2.The efficiency of the selection is good, and the concentrate and tailings can be obtained for one time.

3.Compared with the traditional process, this kind of shaking table doesn’t use the pharmacy, has low energy consumption and is easy to maintain.

4.High enrichment ratio, easy control, low investment and quick results.

5.Consumables have a long service life and do not need to be replaced frequently.

| Name | Grit concentrator table |

Fine sand concentrator table |

Sludge concentrator table |

|

| Bed surface Dimensions |

Length (mm) |

4450 | 4450 | 4450 |

| Driving part Width (mm) |

1855 | 1855 | 1855 | |

| Concentrate part Width (mm) |

1546 | 1546 | 1546 | |

| Max.feeding size(mm) |

2 | 0.5 | 0.15 | |

| Feeding amount (t/d) |

30-60 | 10-20 | 15-25 | |

| Feeding thickness (%) |

25-30 | 20-25 | 15-25 | |

| Stroke (mm) |

16-22 | 11-16 | 8-16 | |

| Frequency (f) |

45-48 | 48-53 | 50-57 | |

| Bed surface Water quantity (t/d) |

80-150 | 30-60 | 10-17 | |

| Bed surface Horizontal obliquity(°) |

2.5-4.5 | 1.5-3.5 | 1-2 | |

| Bed surface Portrait obliquity(%) |

1.4 | 0.92 | ---- | |

| Table board corner(°) |

32-42 | 40 | 42 | |

| Concentrating area(㎡) |

7.6 | 7.6 | 7.6 | |

| Bed surface Length ratio |

2.6 | 2.6 | 2.6 | |

| Shape of side-bed surface |

Rectangle | Zigzag | Triangle | |

| Motor power(kw) |

1.1 | 1.1 | 1.1 | |

| Transmission device |

Eccentricity Linkage | |||

The motor of the shaking table drives the crankshaft to rotate the rocker through the belt and then moves up and down. When the rocker moves downward, the mineral material enters through the mining channel on the inclined surface. Shaker sink provides lateral impact water.

The material with different specific gravity, particle size, and density flushed with rinsing and will be selected and output from the concentrate mouth of shaking table, and the tailings mouth. Thus, the processed ore is the high-quality concentrate. However, because of the replacement of mining gold shaking table, FTM Machinery, as the gold shaking table supplier, had improved a lot in term of its throughput and accuracy.

The shaking table is working

1.Quality Inspection before installing. Users should check whether the parts is conplete and parts of the bed meet the requirements of the drawings.

2.When the hammock is used, you should prevent partial deformation of the side plate and must not hit the bed surface.

3.Install the connector and four connecting blocks before hoisting the table, and adjust the height and exact position. Table surface installation center is consistent with bedside connector center.

4.After checking the installation connections, the empty shaking table runs for 1-2 hours to check whether the bed surface is running smoothly, whether the connection is loose, shaking or sliding, whether the lubrication is good, and 2whether the lateral slope adjustment is flexible and stable.

5.After the shaking table is installed, the connection screw hole should be in line. The gap between support and connection area cannot be too large to prevent the generation of noise and abrasion.

6.If there is no problem with empty shaking table, you can put the ore there. according to the ore transportation and zoning on the shanking table surface, adjusting the ore concentration and concentration, stroke, cross slope and flushing water volume, etc.

| Name | Max.feeding size(mm) |

Bed surface Water quantity (t/d) |

| Grit concentrator table |

2 | 80-150 |

| Fine sand concentrator table |

0.5 | 30-60 |

| Sludge concentrator table |

0.15 | 10-17 |

| Name | Grit concentrator table |

Fine sand concentrator table |

Sludge concentrator table |

|

| Bed surface Dimensions |

Length (mm) |

4450 | 4450 | 4450 |

| Driving part Width (mm) |

1855 | 1855 | 1855 | |

| Concentrate part Width (mm) |

1546 | 1546 | 1546 | |

| Max.feeding size(mm) |

2 | 0.5 | 0.15 | |

| Feeding amount (t/d) |

30-60 | 10-20 | 15-25 | |

| Feeding thickness (%) |

25-30 | 20-25 | 15-25 | |

| Stroke (mm) |

16-22 | 11-16 | 8-16 | |

| Frequency (f) |

45-48 | 48-53 | 50-57 | |

| Bed surface Water quantity (t/d) |

80-150 | 30-60 | 10-17 | |

| Bed surface Horizontal obliquity(°) |

2.5-4.5 | 1.5-3.5 | 1-2 | |

| Bed surface Portrait obliquity(%) |

1.4 | 0.92 | ---- | |

| Table board corner(°) |

32-42 | 40 | 42 | |

| Concentrating area(㎡) |

7.6 | 7.6 | 7.6 | |

| Bed surface Length ratio |

2.6 | 2.6 | 2.6 | |

| Shape of side-bed surface |

Rectangle | Zigzag | Triangle | |

| Motor power(kw) |

1.1 | 1.1 | 1.1 | |

| Transmission device |

Eccentricity Linkage | |||

| Name | Max.feeding size(mm) |

Feeding amount (t/d) |

| Grit concentrator table |

2 | 30-60 |

| Fine sand concentrator table |

0.5 | 10-20 |

| Sludge concentrator table |

0.15 | 15-25 |

Related:

Contact

E-mail:vip@sinoftm.com

Address: No.168 Wutong Street, High-Tech Industrial Development Zone of Zhengzhou City, China.

Hot Products

Future Prospect

We would like to cooperate with customers all around the world, and welcome you sincerely !

Inquiry Online 7×24 Online